NANO ULTRA

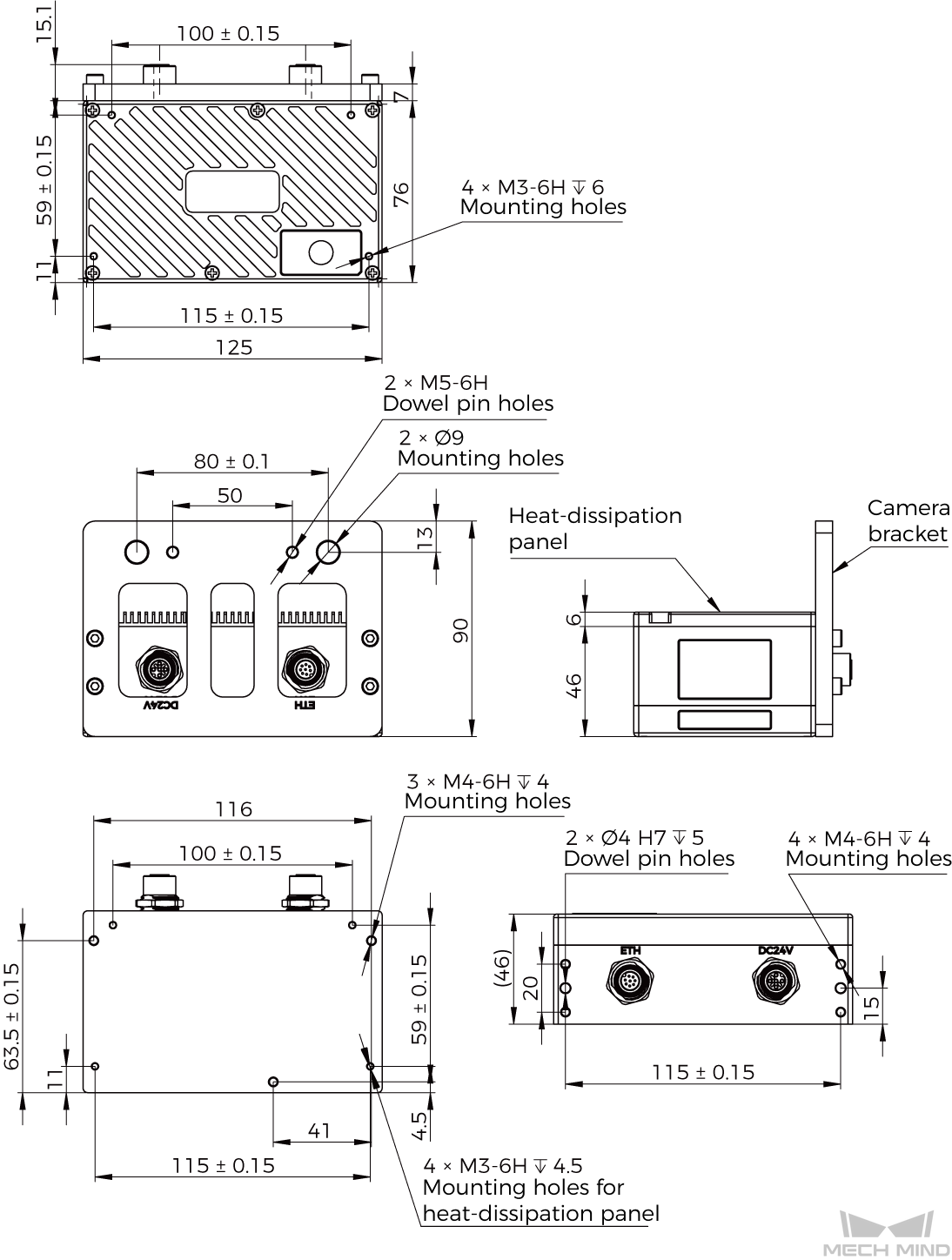

Physical Specifications

Model |

NANO ULTRA |

|---|---|

Dimensions(1) |

125 × 46 × 76 mm |

Weight(1) |

0.7 kg |

Baseline |

86 mm |

Light source |

Blue LED (440 nm, RG2) |

2D image color |

Monochrome |

Operating temperature |

0–45°C |

Operating humidity |

0–85%RH, non-condensing |

Storage temperature |

-20–60°C |

Communication interface |

Gigabit Ethernet |

Input |

24 VDC, 3.75 A |

Power |

Idle: 8 W Average: 12 W Peak: 37 W |

IP rating(2) |

IP65 |

Cooling |

Passive |

Flatness tolerance for mounting surface(3) |

± 0.05 mm |

Vibration tolerance(4) |

Sinusoidal vibration along the X-, Y-, and Z-axes, 10–57 Hz, 1.5 mm peak-to-peak value, 3 hours per axis |

Shock tolerance(5) |

Half sine shock pulses along the positive and negative directions of the X-, Y-, and Z-axes, 147 m/s2 (15 g), 11 ms, 3 shocks per direction, 18 shocks in total |

(1) Heat-dissipation panel not included.

(2) Test implemented based on IEC 60529. 6: dust-tight; 5: protected against water jets.

(3) The flatness of the surface used to mount the camera should satisfy this requirement.

(4) Test implemented based on IEC 60068-2-6.

(5) Test implemented based on IEC 60068-2-27.

Performance Specifications

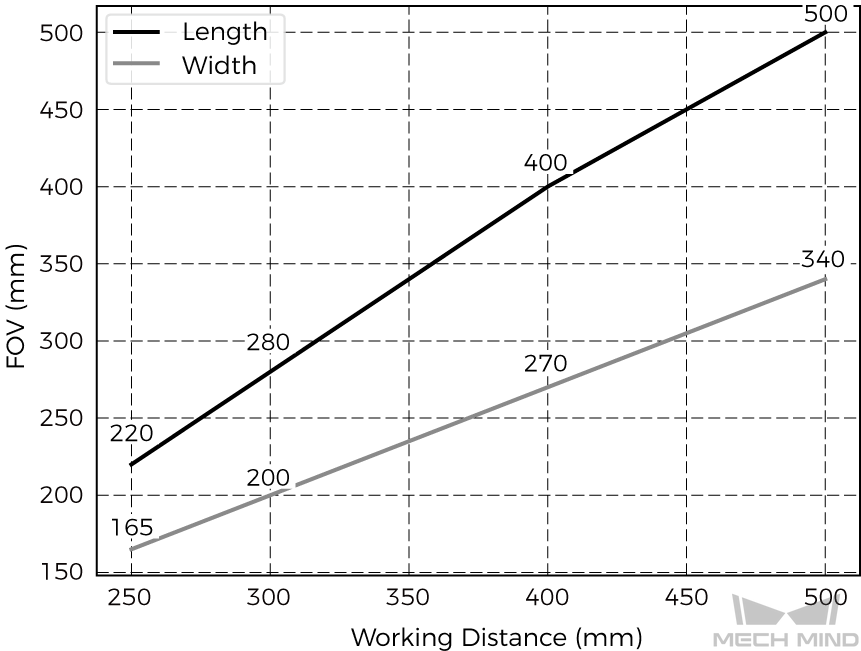

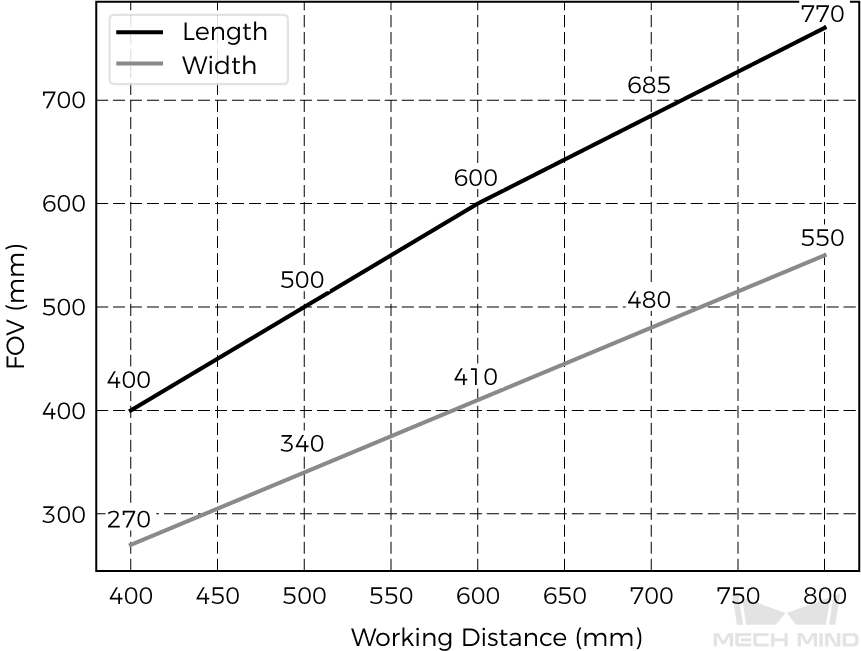

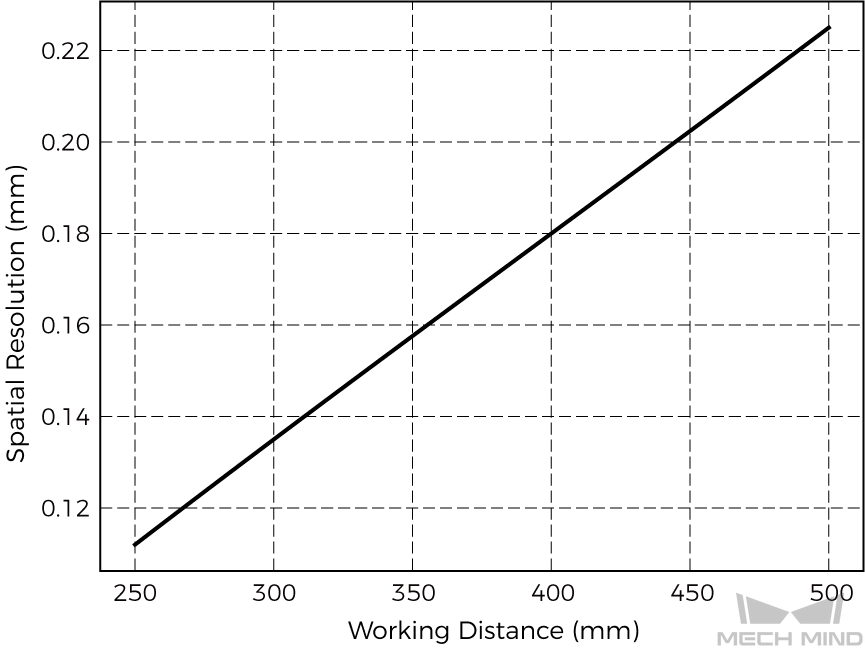

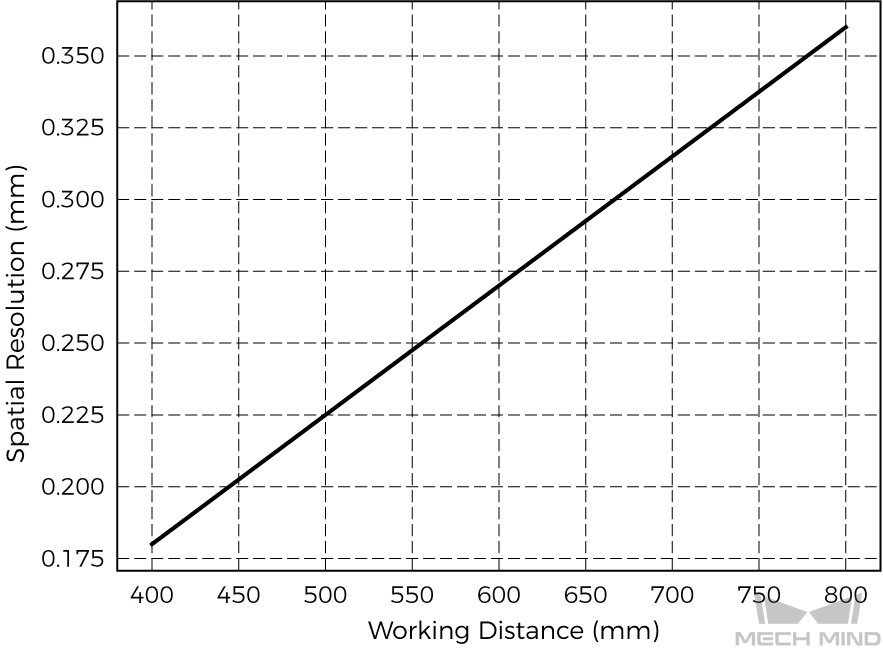

| Working distance | 250–500 mm | 400–800 mm |

|---|---|---|

Recommended working distance |

250–500 mm |

400–800 mm |

Object focal distance(1) |

350 mm |

700 mm |

FOV (near) |

220 × 165 mm @ 0.25 m |

400 × 270 mm @ 0.4 m |

FOV (far) |

500 × 340 mm @ 0.5 m |

770 × 550 mm @ 0.8 m |

Resolutions(2) |

2400 × 1800 |

|

Typical capture time(3),(4) |

0.5–0.9 s |

|

Recommended warm-up time(3),(5) |

30 min |

|

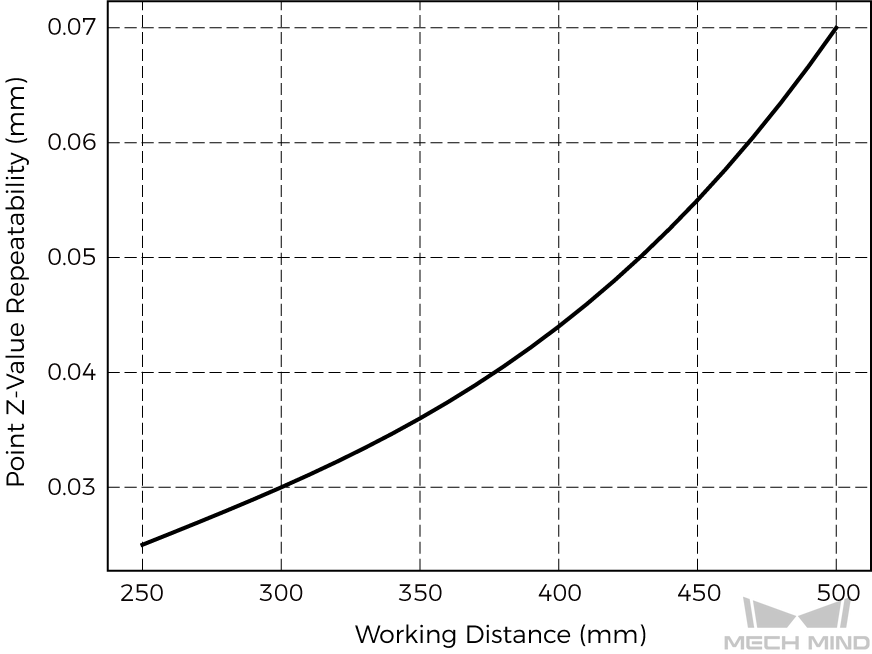

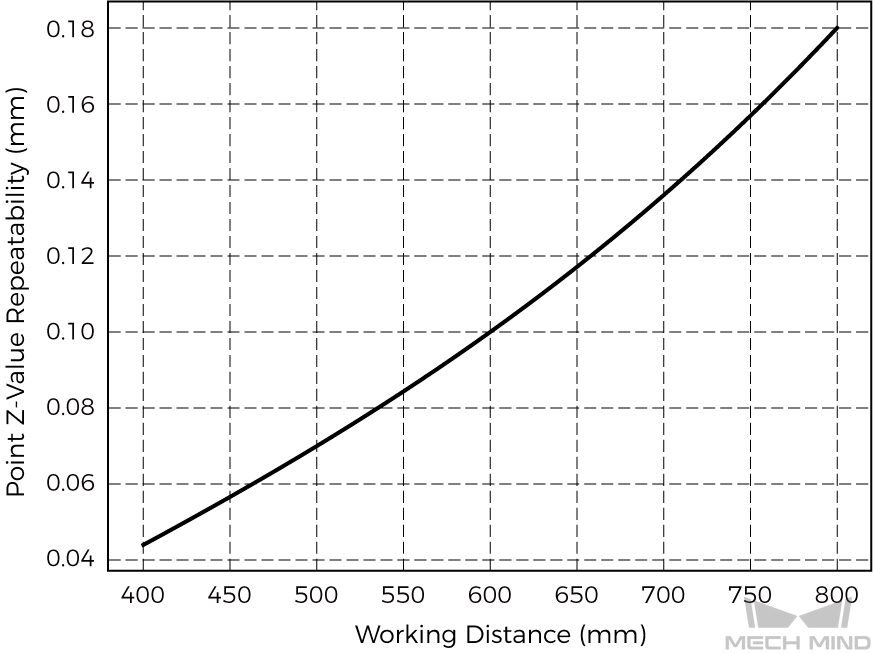

Point Z-value repeatability (1σ)(3),(6) |

0.045 mm @ 0.4 m |

0.1 mm @ 0.6 m |

Measurement accuracy (VDI/VDE)(3),(7) |

0.1 mm @ 0.4 m |

0.1 mm @ 0.6 m |

(1) The object focal distance of the 2D camera inside the product.

(2) Can be changed to 1200 × 900 through Mech-Eye Viewer.

(3) Unless otherwise specified, this test was conducted under the standard test conditions.

(4) The range of time taken to acquire data using Mech-Eye Viewer in the Fast and Accurate fringe coding mode.

(5) The recommended warm-up time required to guarantee data accuracy to the listed values. For the warm-up method, refer to the user manual (The data acquisition interval is 10 s). Please adjust the warm-up time based on the actual data acquisition interval, ambient temperature, and heat-dissipation conditions.

(6) The standard deviation of the 100 measured depth values of each point on the target object was calculated, and then the median of all the standard deviations was taken. The target object was a white ceramic plate with a rough surface. The Point Cloud Processing parameters were set to Off.

(7) Test implemented with reference to VDI/VDE 2634 Part 2.

Certifications

CE

Hereby [Mech-Mind Robotics Technologies Co., Ltd.] declares that [NANO ULTRA] is in compliance with the Electromagnetic Compatibility Directive 2014/30/EU.

The full text of the EU Declaration of Conformity is available at https://downloads.mech-mind.com/?tab=tab-eu-dec

Standard Test Conditions

Working distance(1) |

250–500 mm |

400–800 mm |

||

|---|---|---|---|---|

Ambient temperature |

15–30°C |

|||

Ambient humidity |

0–85%RH, non-condensing |

|||

Ambient light intensity |

200–1000 lx |

|||

Camera parameters(2) |

10 ms |

|||

Timed (Exposure Time: 80 ms) |

||||

0 dB |

||||

High |

||||

Accurate |

||||

Normal |

||||

Normal |

||||

Normal |

||||

Tested region(3) |

Length: 90% of FOV length Width: 90% of FOV width Position: center of FOV |

|||

Resolutions |

2400 × 1800 |

|||

(1) For the object focal distance of 350 mm, the working distance used in tests is 250–500 mm. For the object focal distance of 700 mm, the working distance used in tests is 400–800 mm.

(2) Parameters not listed are set to their default values.

(3) Test data was obtained from this region.