Detect and Measure Hole on Surface

Description

This Step is used to detect the hole on a surface and output the location and radius of the detected hole.

Usage Scenario

Quality inspection, equipment calibration, object recognition, and positioning can be performed by locating and measuring holes on the surface of the workpiece.

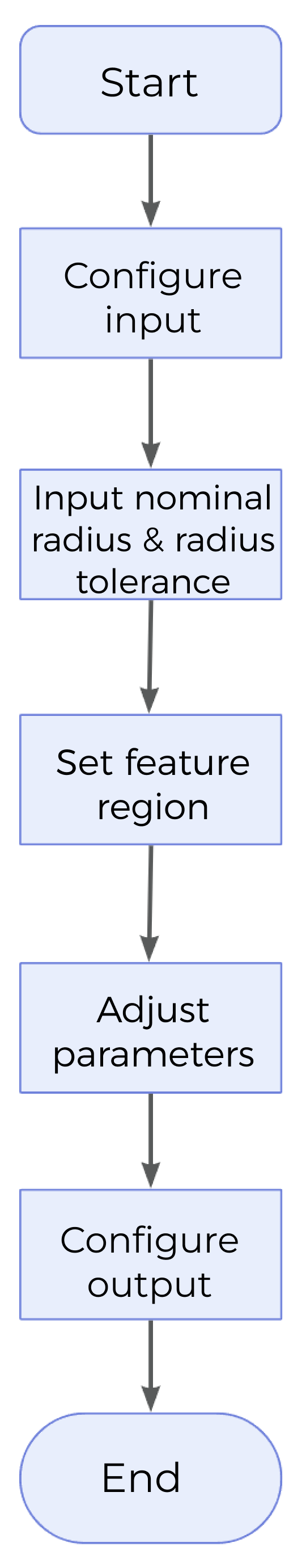

Workflow

The process of configuring this Step is shown below.

-

Configure the input. Connect the ports manually or select the input(s) under Input in the parameter configuration panel.

-

Set Nominal Radius and Radius Tolerance under Parameters.

-

Configure the feature region and reference plane (optional).

-

Select the desired output(s) under Output. For an expandable output item, click ▶ and configure the Min and Max values of the acceptable range.

Parameter Description

- Nominal Radius

-

The expected radius of the hole, i.e. the standard radius of the hole.

- Radius Tolerance

-

The allowable maximum variation of measured radius from the nominal radius (+ / - from the nominal radius).

- Use Local Detection

-

The center of the hole to be detected must be within the feature region. For Use Local Detection to be selected, this condition must be met, otherwise no measurement can be performed effectively.

-

Unselected (default): The hole to be detected is completely within the feature region.

-

Selected: Only part of the hole is within the feature region.

-

- Use Depth Limit

-

Once this option is selected, set Depth Threshold for data points. Points with depth values (relative to the measurement plane or reference plane) above the set threshold will be removed from hole calculation.

- Feature Region

-

Configure the feature region to ensure that the hole to be detected is within the feature region. For more information on how to set the feature region, please refer to Set the Feature Region.

The data in the feature region can be used to fit a measurement plane as a reference. Once set, the reference plane will be used as reference. - Use Reference Plane

-

In cases where the surface around the hole is not flat, you can set a Reference Region to fit the reference plane so that the detected hole is on the reference plane.

-

Unselected: All data points in the feature region will be used to fit a measurement plane.

-

Selected: Once the option is selected, you can set One or Two reference region(s) to fit a reference plane aligned with the hole to be detected.

-

- Tilt Correction

-

The plane where the detected hole is located may be tilted compared to the actual plane, which can corrected in one of the following ways:

Options: Autoset, Custom

-

Autoset: The tilt of the hole relative to the measurement plane or reference plane is automatically detected and corrected.

-

Custom: Set X Angle and Y Angle manually to correct the tilt of the hole.

-

Output Description

Select the output item(s) according to the actual measurement requirements. Then the corresponding data will be output after the Step is run.

|

If you select an expandable output item, you must expand it by clicking ▶, and then set the Min and Max values to determine the acceptable range. If the output value falls within the qualified range, the measurement is judged as passing (OK), or else it is judged as failing (NG). |

| Output Item | Description |

|---|---|

Hole Center X |

The X value of the hole center. |

Hole Center Y |

The Y value of the hole center. |

Hole Center Z |

The Z value of the hole center. |

Radius |

The radius of the hole. |

Hole Center |

The center point of the hole. |

Troubleshooting

Invalid ROI

| No. | Error | Possible Causes | Solution |

|---|---|---|---|

1 |

Insufficient data points defined by the feature region |

- |

Adjust the feature region so that sufficient data points are included. |

2 |

Insufficient data points defined by reference region(s) |

- |

Adjust the reference region so that sufficient data points are included. |

3 |

No hole detected |

|

|

4 |

Failure to reproject |

|

|

5 |

Insufficient data points involved in hole detection in the feature region |

|

|

Invalid Parameter

| No. | Error | Possible Causes | Solution |

|---|---|---|---|

1 |

Unreasonable nominal radius |

The set nominal radius is too large or too small. |

Reset Nominal Radius appropriately. |

2 |

Large difference between the measured radius and the set nominal radius |

- |

Reset Nominal Radius, Radius Tolerance, or adjust the feature region. |

3 |

Unreasonable radius tolerance |

The set radius tolerance is too large or too small. |

Reset Radius Tolerance appropriately. |