Getting Started Tutorial: Vision-Guided Robotic Depalletizing of Cartons (Master-Control Communication)

In this tutorial, you will learn how to deploy a simple 3D vision-guided robotic application of depalletizing cartons in the Master-Control communication mode.

Application Overview

-

Camera: Mech-Eye DEEP camera, mounted in eye to hand (ETH) mode

-

Calibration board: It is recommended to use the calibration board CGB-050

-

Robot: ABB_IRB_1300_11_0_9

-

Workobject: single-case cartons

-

IPC: Mech-Mind IPC STD

-

Used software: Mech-Vision 1.8.2, Mech-Viz 1.8.2, Mech-Eye Viewer 2.3.1

-

Communication mode: Master-Control communication

|

If you are using a different camera model, robot brand, or workobject than in this example, please refer to the reference information provided in the corresponding steps to make adjustments. |

Getting Started Tutorial: Vision-Guided Robotic Depalletizing Overview

|

Explanation of Terms

Pallet |

A platform device used to hold goods (such as cartons) |

Depalletizing |

A task that a robot performs to disassemble objects from a pallet as required under the vision guidance |

Palletizing |

A task that a robot performs to place objects at specified positions on a pallet under the vision guidance |

Single-case depalletizing |

Depalletize single-case cartons (with the same dimensions) from a pallet |

Mixed-case depalletizing |

Depalletize single-case cartons (with different dimensions) from a pallet |

How to Deploy a Vision-Guided Robotic Application?

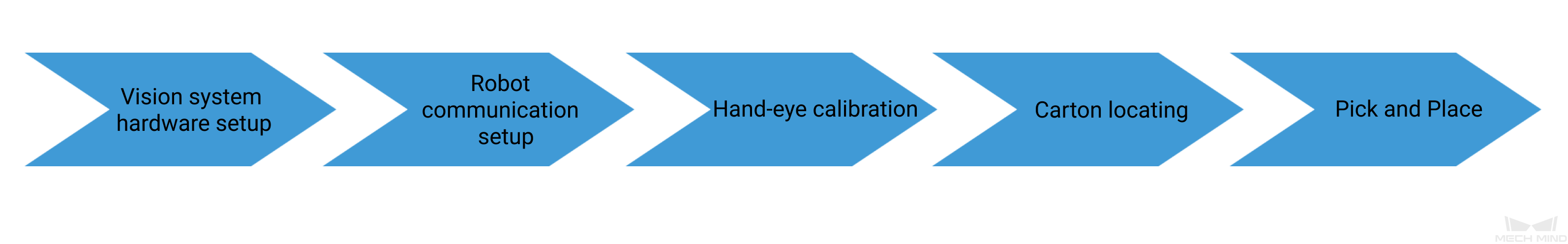

The deployment of the vision-guided robotic application can be divided into six phases, as shown in the figure below:

The following table describes the six phases of deploying a vision-guided robotic application.

| No. | Phase | Description |

|---|---|---|

1 |

Vision Solution Design |

Select the hardware model according to the project requirements, determine the mounting mode, vision processing mode, etc. (This tutorial has a corresponding vision solution, and you do not need to design it yourself.) |

2 |

Vision system hardware setup |

Install and connect hardware of the Mech-Mind Vision System. |

3 |

Robot communication setup |

Load the robot master-control program and the configuration files to the robot system and set up the communication between the vision system and the robot, thus helping the Mech-Mind Vision System obtain control over the robot. |

4 |

Hand-eye calibration |

Perform the automatic hand-eye calibration in the eye-to-hand setup, to establish the transformation relationship between the camera reference frame and the robot reference frame. |

5 |

Carton locating |

Use the case project “Single_Case_Cartons” to locate cartons and provide guidance for accurate robot picking. |

6 |

Pick and place |

Build the workflow for a Mech-Viz project to plan a collision-free robot path for picking and placing cartons. |

Next, follow subsequent sections to complete the application deployment.