Manual Re-Calibration in the Eye-to-Hand Setup (Four-Axis Robots - Using Multiple Random Calibration Board Poses Method)

This how-to guide introduces how to complete the manual re-calibration for four-axis robots using the multiple random calibration board poses method in the eye-to-hand (ETH) setup.

Preparation before Calibration

Before hand-eye re-calibration, you need to finish the following preparations:

-

Locate the calibration board provided with the project. Ensure that the circles of the calibration board are clearly visible and without obvious scratches, and the board does not suffer from deformations.

Please prepare the calibration board according to the following requirements:

-

Ensure that the circles of the calibration board are clearly visible and without obvious scratches, and the board does not suffer from deformations.

-

Mount the robot-specific bracket for calibration board onto the robot flange, and then mount the calibration board onto the bracket. Make sure that the calibration board is attached securely, and that the board is parallel to the XY plane of the robot flange frame.

If an undetachable gripper is connected to the robot flange, you can attach the calibration board directly to the gripper.

-

Clear the workstation of any materials to ensure that the calibration area is free of obstructions.

-

Manually control the robot to move the calibration board to the starting point. For the automatic calibration in the ETH setup, the starting point is the bottom center of the camera’s field of view (the robot will move the calibration board upwards during calibration).

Adjust the Effect of Calibration Board’s Point Cloud

-

Open Mech-Eye Viewer to adjust camera parameters.

-

Adjust the 2D parameters to make sure that the 2D image of the calibration board is clear and neither overexposed nor underexposed.

-

Adjust 3D parameters to make sure that the point clouds of the circles on the calibration board are complete and have clear contours. It is recommended to set Surface Smoothing and Outlier Removal to Normal in the Point Cloud Processing section to reduce the point cloud fluctuation range.

-

Make sure that the images and point cloud of the calibration board are up to standard after completing the preceding steps.

Normal Overexposed Underexposed 2D image

Point cloud

Pre-calibration Configuration

-

Open Mech-Vision, select a project in the project list, and then click the Camera Calibration (Standard) button in the toolbar. The Configuration before Calibration window will be prompted.

-

In the Select how to calibrate window, select the Load calibration parameters radio button, select the parameters that were calibrated for the project, and then click the Next button.

-

In the Select parameter usage window, select Continue working on the calibrated camera radio button, and then click the Next button.

Camera status should be displayed as connected. -

In the Select calibration task window, select Recalibrate from the start radio button, and then click the Calibration button. The Calibration (Eye to Hand) window will be prompted.

Till now, you have completed the pre-calibration configuration and can start the calibration procedure.

Calibration Procedure

Connect to Camera

By default, the camera used in the project is set to be connected. Please click the Next button to continue the calibration procedure.

If the camera is not connected, please complete the camera connection by referring to the following instructions:

-

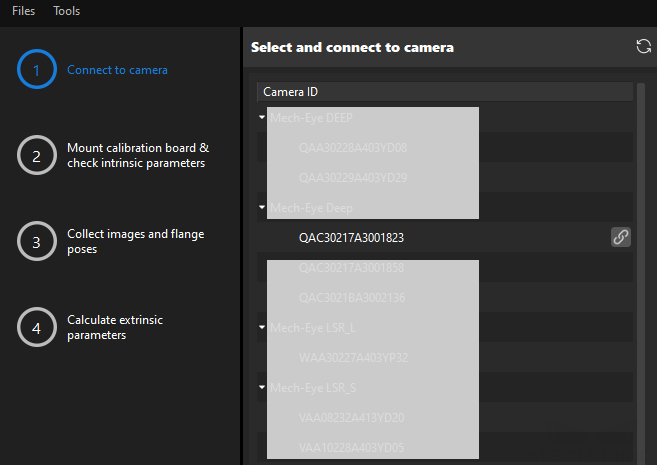

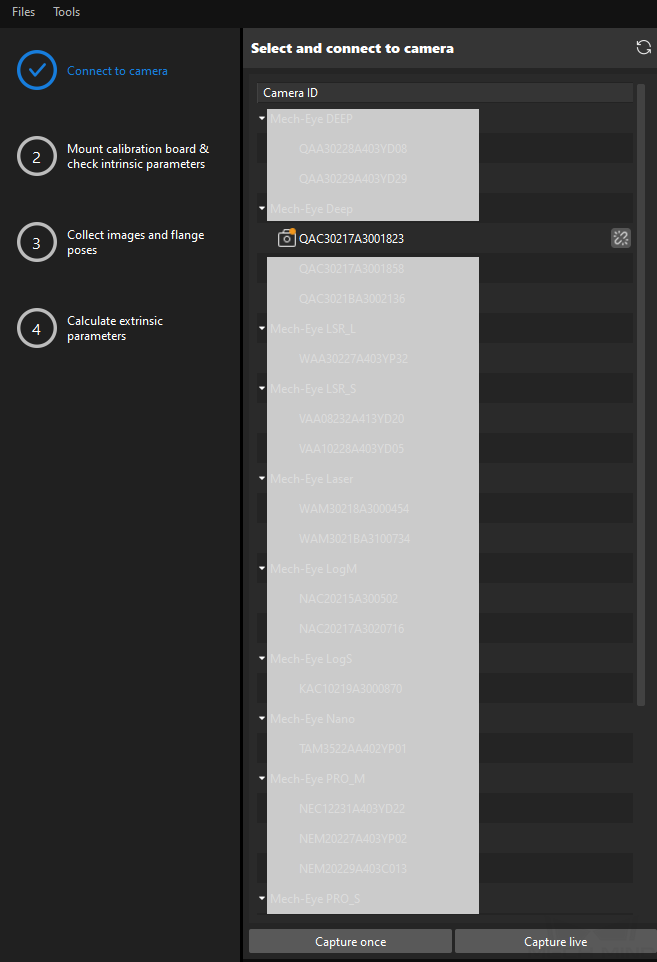

In the Connect to camera step, select the camera to connect in the Camera ID list, and then click the

button or double-click the camera entry to connect to it.

button or double-click the camera entry to connect to it.

-

After the camera is connected, click the Capture live or Capture once button.

-

In the Image viewer panel, ensure that the camera can capture images normally and click the Next button on the bottom bar.

Mount Calibration Board & Check Intrinsic Parameters

-

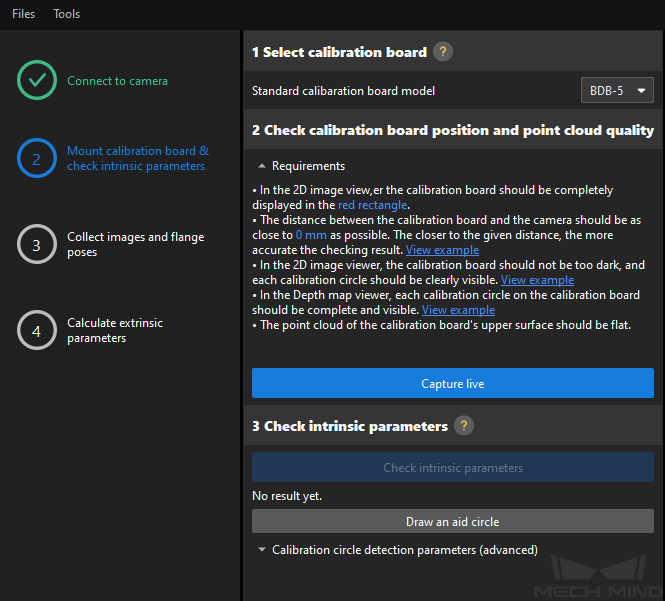

In the Mount calibration board & check intrinsic parameters step, select the calibration board model for the Standard calibration board model parameter according to its model nameplate in the 1 Select calibration board area.

-

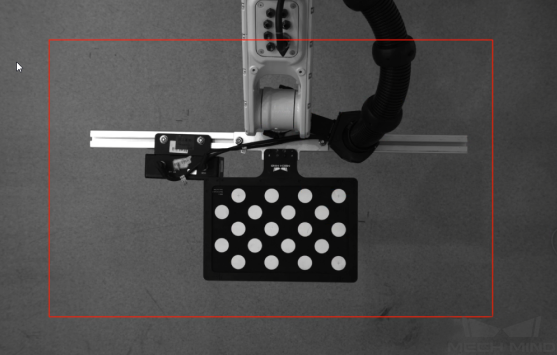

In the 2 Check calibration board position and point cloud quality area, read carefully the requirements on the calibration board position and point cloud quality, and then click the Capture live button. The Capture live button will turn into Stop capturing and detect position.

-

Control the robot to move the calibration board to the proper position (in the red rectangle), and ensure that the 2D image and depth map of the calibration board meet the requirements, and then click the Stop capturing and detect position button.

If the captured images do not meet the requirements, click Open Mech-Eye Viewer button to open the Mech-Eye Viewer software, adjust the 2D and 3D exposure parameters and re-capture images. Please note that you need to change the Parameter group parameter to “calib” first.

-

In the 3 Check intrinsic parameters area, click the Check intrinsic parameters button.

-

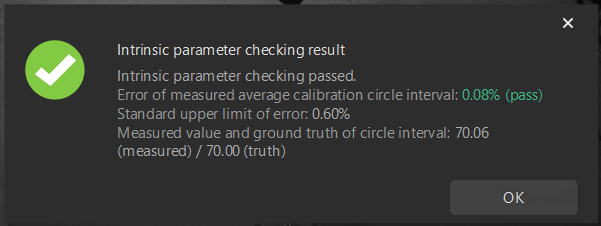

Confirm the results of the camera intrinsic parameter check.

-

If the camera intrinsic parameter check passes, click the OK button in the prompted window, and then click the Next button on the bottom bar.

-

If the camera intrinsic parameter check fails, adjust detection parameters by drawing aid circles or manually adjusting the calibration circle detection parameters, and then click the Recheck intrinsic parameters button. If the intrinsic parameter check still fails, please contact Technical Support.

-

Draw Aid Circle

-

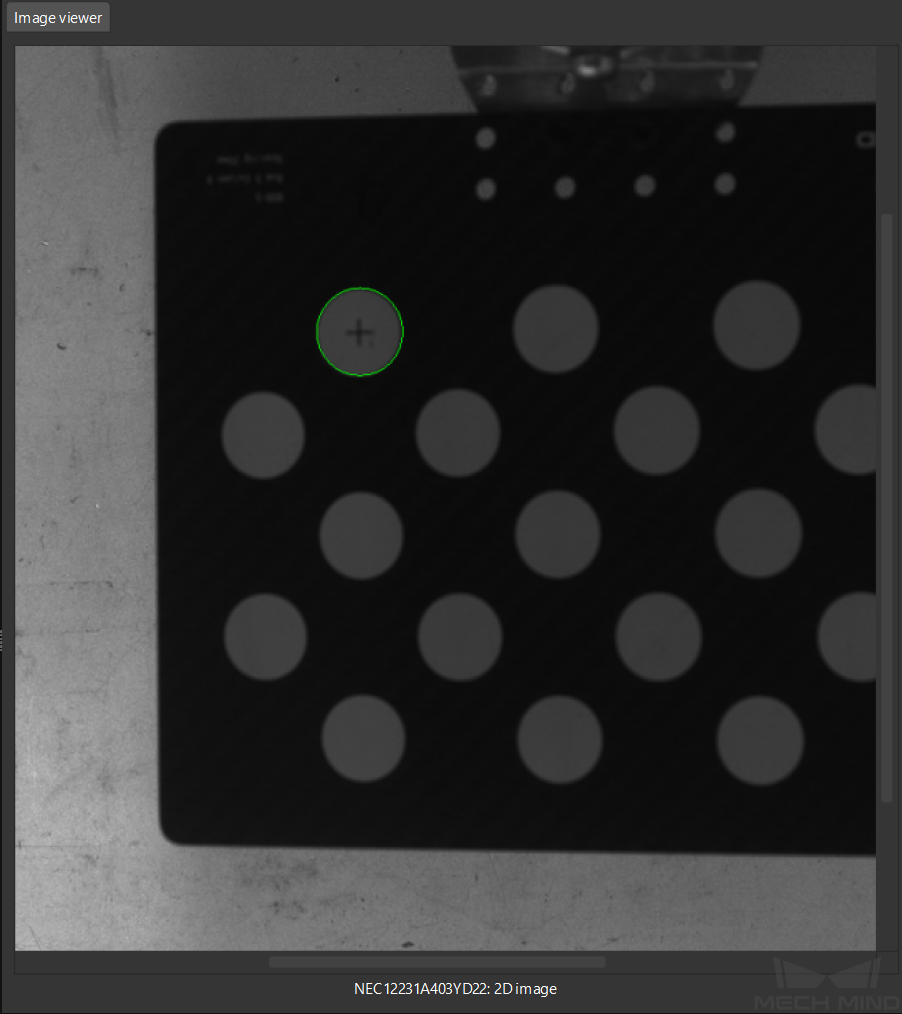

To draw an aid circle, click the Draw an aid circle button.

-

In the right Image viewer panel, right-click the calibration board image, clear the Fit to window checkbox, press the Ctrl key and drag the roller to adjust the image to a suitable size.

-

Move the mouse pointer to the cross center point of the calibration circle, press the left mouse button and make the aid circle completely include the calibration circle and then release it.

-

Click the Recheck intrinsic parameters button, and confirm that the camera intrinsic parameter check passes.

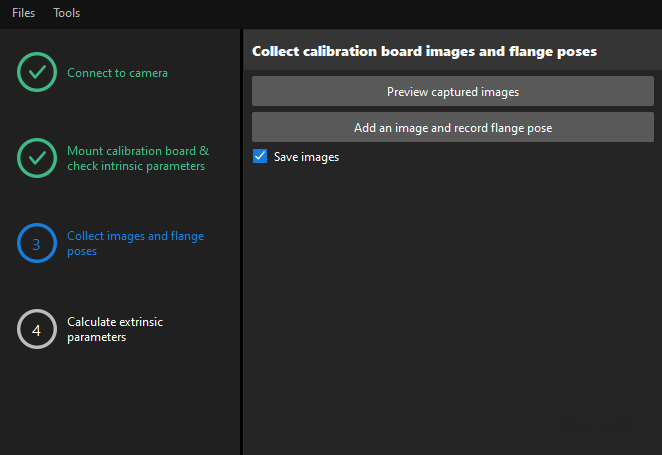

Collect Images and Flange Poses

-

In the Collect images and flange poses step, select the Save images checkbox (selected by default, recommended). If you do not need to save images of calibration boards, clear this checkbox.

-

Control the robot to move to different calibration points and then click the Add an image and record flange pose button.

Please refer to the calibration point poses recorded during the project deployment phase for the robot’s movement calibration. -

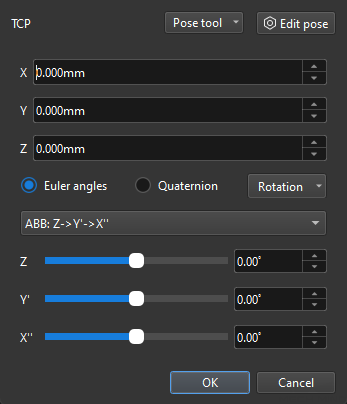

In the prompted window, enter the robot flange pose.

-

Confirm that the number of the currently recognized calibration circles meets the requirements, and then click the Next button on the bottom bar.

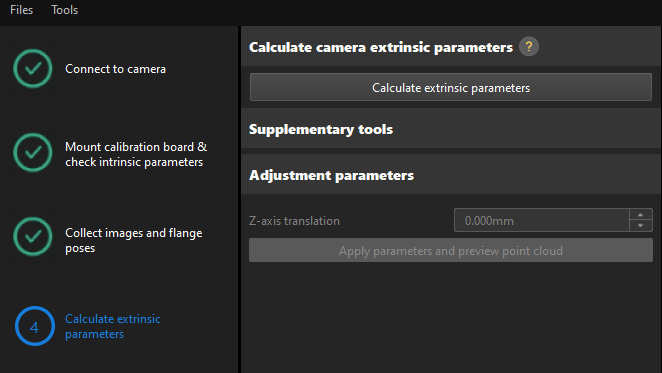

Calculate Extrinsic Parameters

-

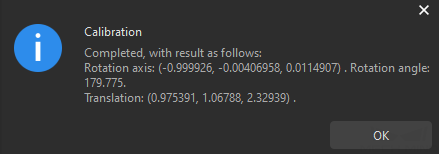

In the Calculate extrinsic parameters Step, click the Calculate extrinsic parameters button.

-

In the prompted window indicating calibration success, click the OK button.

-

Calculate the Z-axis translation of the extrinsic parameters.

Due to the lack of degrees of freedom in rotation in four-axis robots, the captured images during calibration may lack the images for calibration board rotation. After calibration, you need to manually adjust the Z-axis value of the extrinsic parameters. -

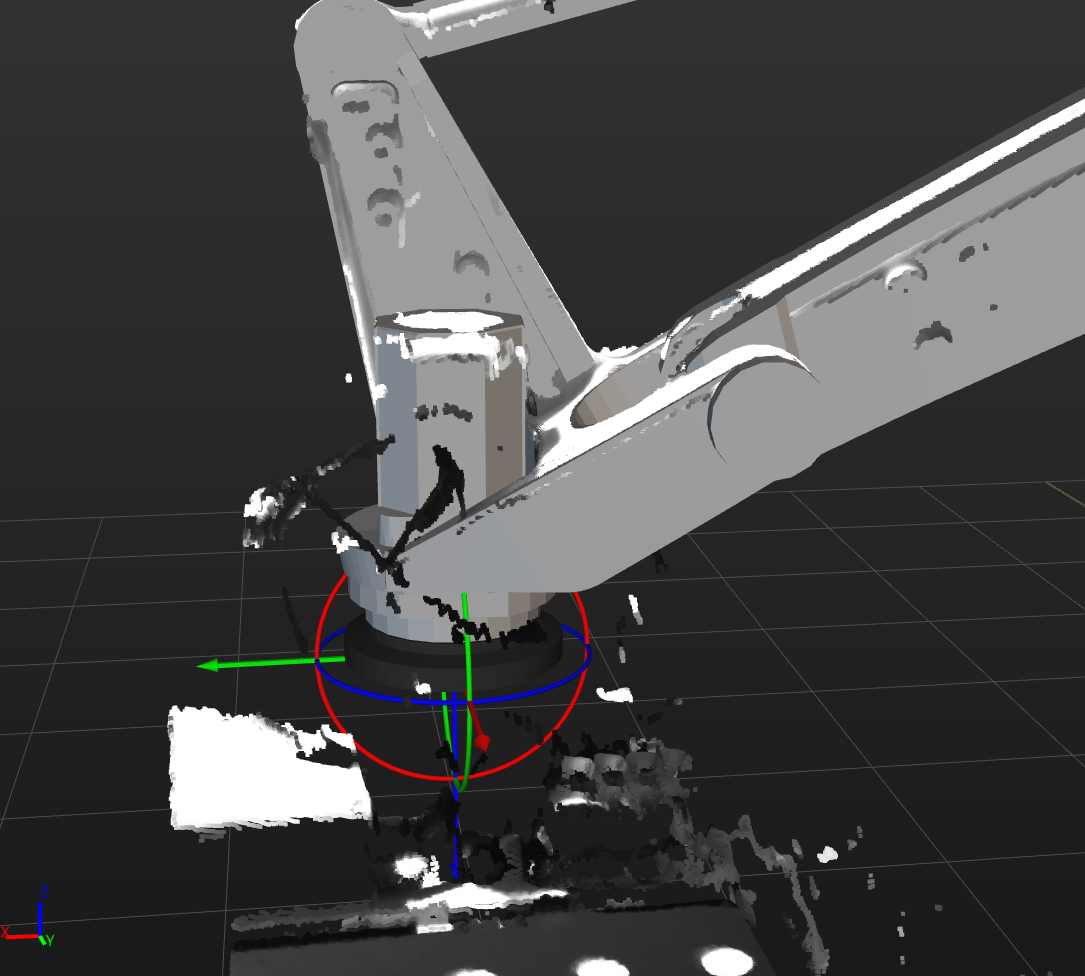

Control the robot to move to a position in the camera’s field of view, and then click the Apply parameters and preview point cloud button in the Adjust parameters area.

-

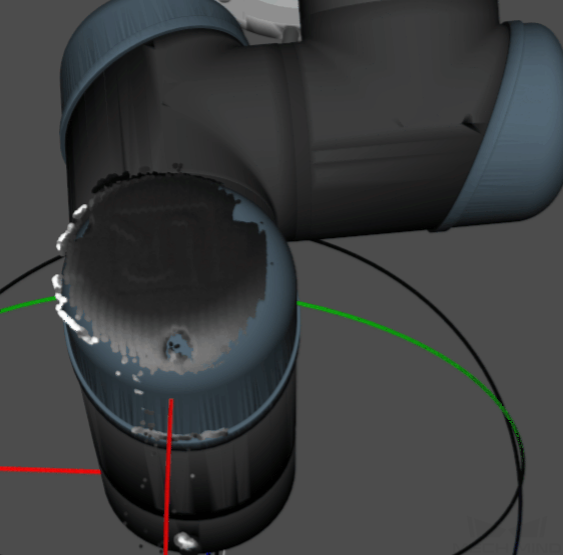

In Mech-Viz, confirm whether the robot’s actual point cloud coincides with the robot model.

-

Check the robot’s current pose in the teach pendant, and enter the robot’s current JPs in the Robot panel of Mech-Viz.

-

In the 3D Simulation Area of Mech-Viz, confirm whether the robot’s actual point cloud coincides with the robot model. If yes, proceed to the next step. Otherwise modify the value of the Z-axis translation parameter in Mech-Vision, and click the Apply parameters and preview point cloud button. Repeat this operation until the robot’s actual point cloud coincides with the robot model.

-

-

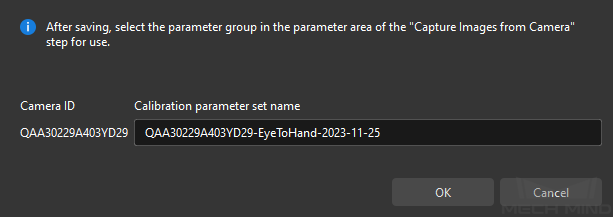

Click the Save button on the bottom bar. In the prompted Save Calibration Files dialog box, click the OK button. The camera calibration result will be automatically saved in the “calibration” directory of the project.

Till now, the calibration process is completed.

Verify Calibration Results

After calculating the extrinsic parameters, you can use any of the following methods to verify if the calibration results are valid.

View Extrinsic Parameter Calibration Report

After calculating the extrinsic parameters, you can click View extrinsic parameter calibration report button. The extrinsic parameter calibration report will be automatically displayed after it is generated.

If the calibration results of the Euler angle convention check, camera accuracy check, and robot absolute accuracy check are all “Pass” (or there is no significant error), then the extrinsic parameters are calibrated successfully and can be used.

If any of the checks fails, please follow the recommendations provided in the report and re-calibrate the extrinsic parameters until the check passes.

Roughly Check Coincidence Degree between the Point Cloud of the Robot and the Robot Model in Scene Viewer

-

After calibration, move the robot arms into the field of view of the camera.

-

In the Calculate extrinsic parameters step, click the Calculate extrinsic parameters button. This operation will trigger the camera to capture images and generate the point clouds of the robot.

-

Click Scene viewer to check the coincidence degree between the point cloud of the robot and the robot model.

If the point cloud of the robot roughly coincides with the robot model, the calibration is successful.

Change the Extrinsic Parameter File

After hand-eye calibration, it is necessary to change the extrinsic parameter file used in the current Mech-Vision project to a new one.

-

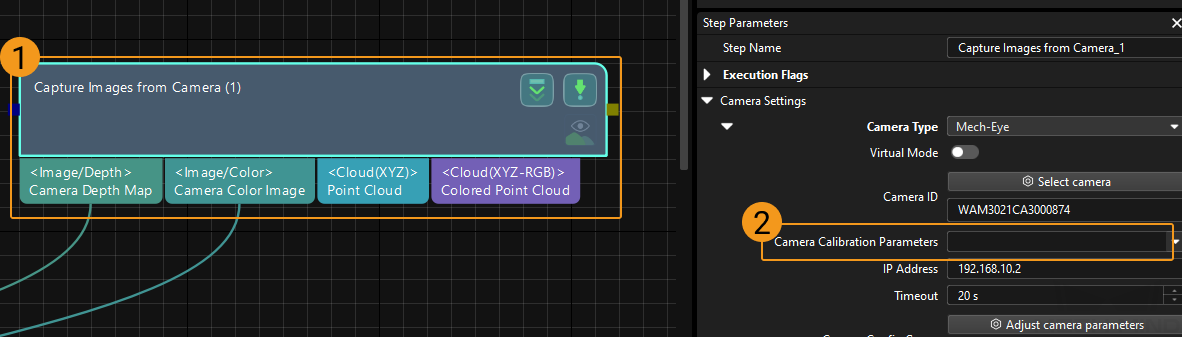

Select the Capture Images from Camera Step.

-

In the Step Parameters panel, click

of the Camera Calibration Parameters parameter, and select the newly calibrated extrinsic parameter file.

of the Camera Calibration Parameters parameter, and select the newly calibrated extrinsic parameter file.