Master-Control Communication Setup

This guide shows you how to set up Master-Control communication with a JAKA robot.

Check Controller and Software Compatibility

|

The models and versions listed below are tested and can be used. For other models and versions, you may refer to this guide for operation. If any issues occur, please contact Mech-Mind Technical Support. |

-

Controller version: 1.5.12, 1.5.13, 1.7.0 or 1.7.1

Click

in the upper-right corner of the main interface to check the controller version.

in the upper-right corner of the main interface to check the controller version. -

JAKA APP version: The JAKA APP version must correspond to the controller version.

Set up the Network Connection

Connect the Hardware

You can select one of the following two methods to complete hardware setup:

-

Plug the IPC’s Ethernet cable into the Ethernet interface inside the accessory panel on the front of the controller, as shown below.

-

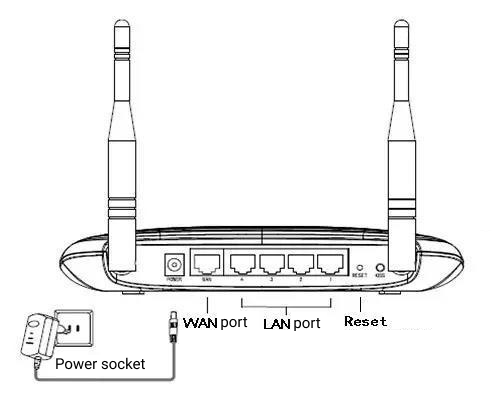

Connect both the IPC and the controller to the same router with Ethernet cables. The IP addresses of the two must be in the same subnet.

Install JAKA APP

Download and install JAKA APP mobile version or PC version. JAKA APP replaces the bulky handheld robot teach pendant. You can simply install it on a mobile device or PC, ensure it is on the same local network as the robot, and connect to the robot to operate it.

| If you are using multiple cameras, make sure the router has enough LAN ports for the IPC and cameras. |

Set the IP Address

-

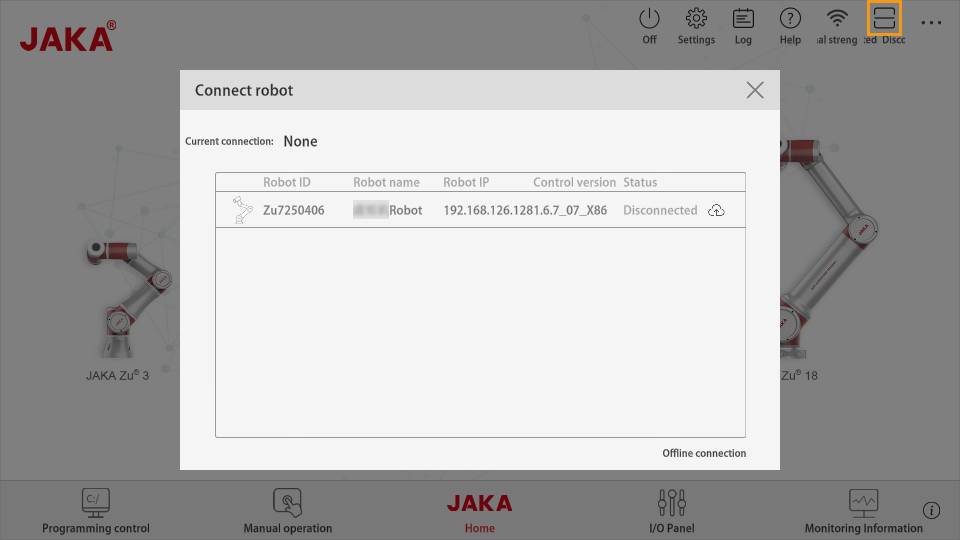

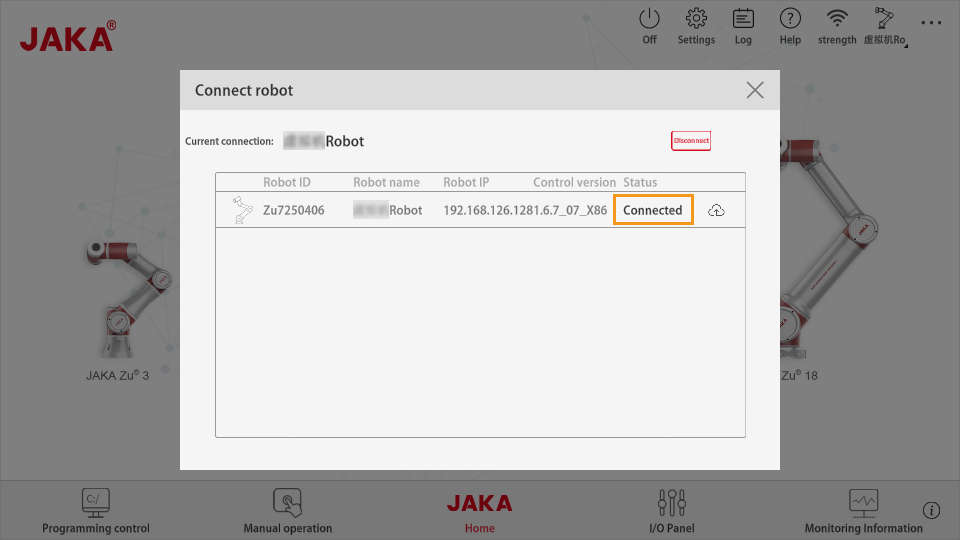

Open JAKA APP, click Disconnected in the upper right to Connect robot, and then click

to enter the password.

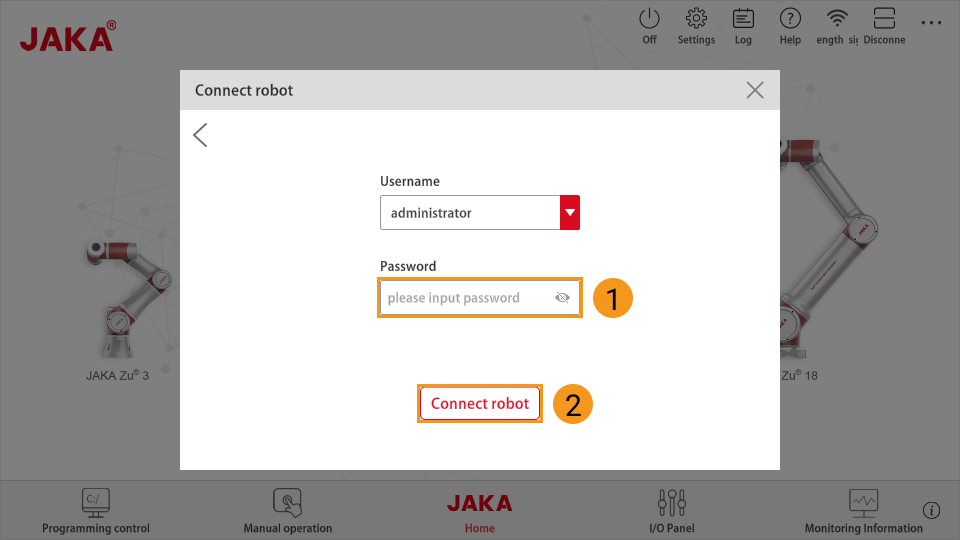

to enter the password.

-

Enter the password for administrator (the default password is jakazuadmin), and click Connect robot.

-

If successfully connected, the Status of the robot should change to Connected.

-

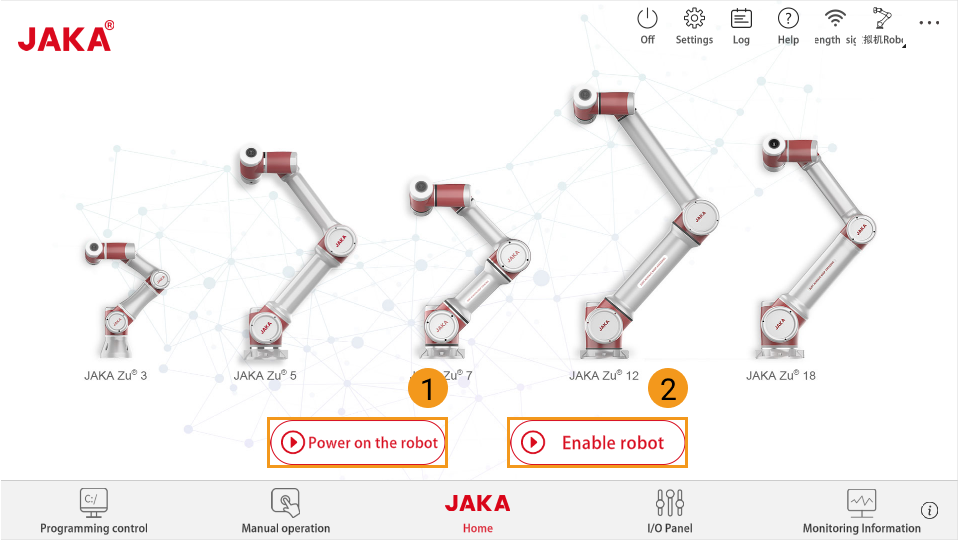

Click Power on the robot and then Enable robot to power on the robot.

After powering on the robot, make sure to enter the end-effector load value. Otherwise, the robot may experience significant up-and-down fluctuation at the moment of startup, which can lead to potential dangers.

-

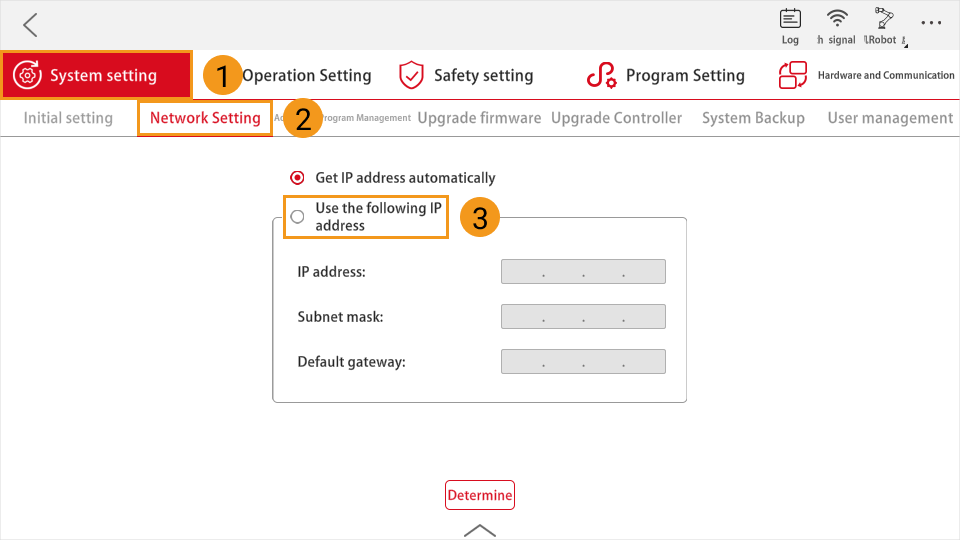

Click settings

in the upper right. Go to to set the IP address. JAKA APP should be in the same subnet as the IPC.

in the upper right. Go to to set the IP address. JAKA APP should be in the same subnet as the IPC.

Test Robot Connection

Create a Mech-Viz Project

-

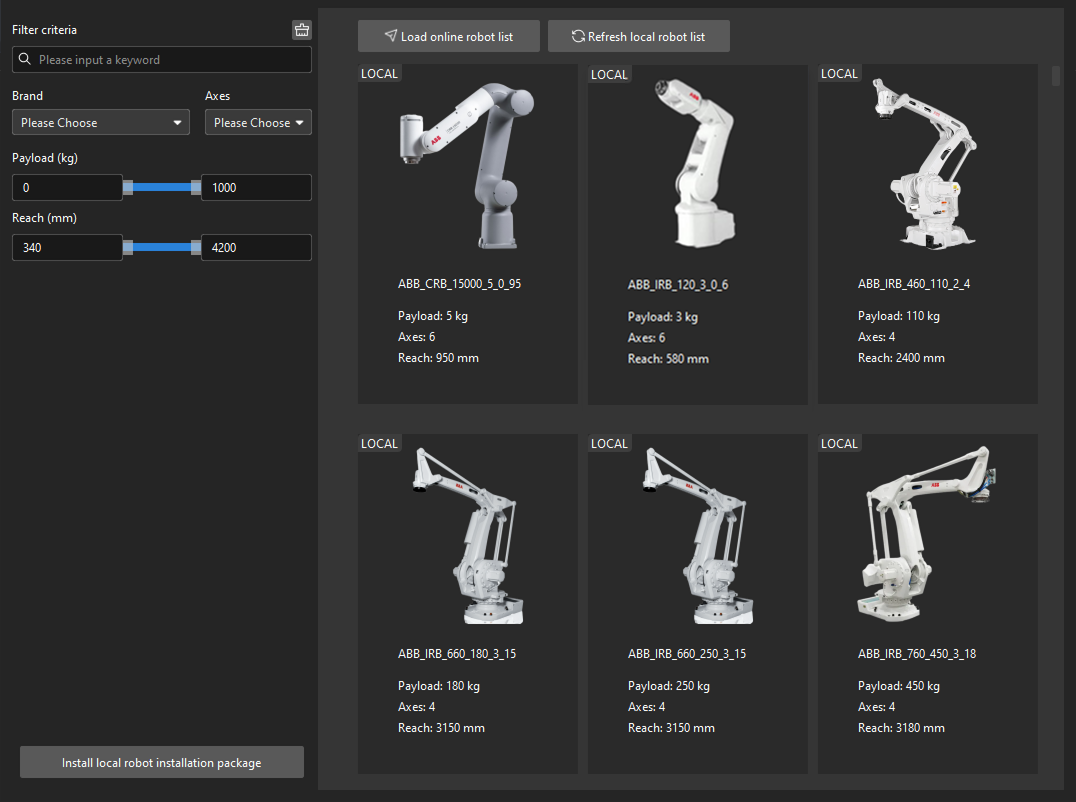

Open Mech-Viz, press Ctrl + N on the keyboard to create a new project. Select the robot model corresponding to your real robot brand and model on the interface as shown below.

-

Press Ctrl + S and create or select a folder to save the project.

-

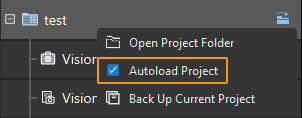

Right-click the project name in the left panel in Mech-Viz and select Autoload Project.

Connect to the Robot

-

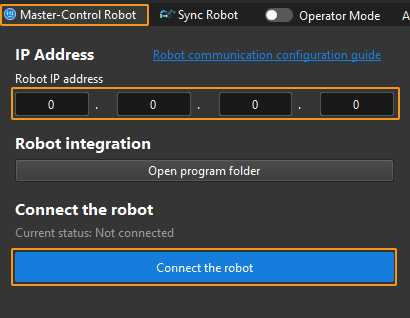

Click Master-Control Robot on the toolbar of Mech-Viz.

-

Input the IP address of the real robot in Robot IP address (the IP address in the picture is only an example). Click Connect the robot.

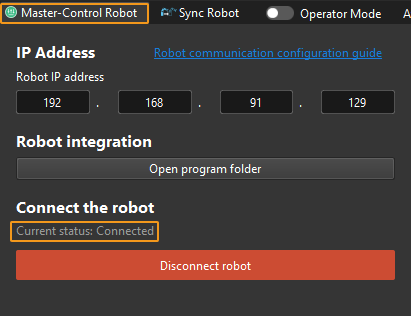

If Mech-Viz successfully connects the real robot, the current status will change to Connected. Meanwhile, the icon in the toolbar will turn from blue to green.

If the connection fails, please double-check the robot IP address.

Move the Robot

|

Before using Mech-Viz to control the robot, please pay attention to the following points:

|

-

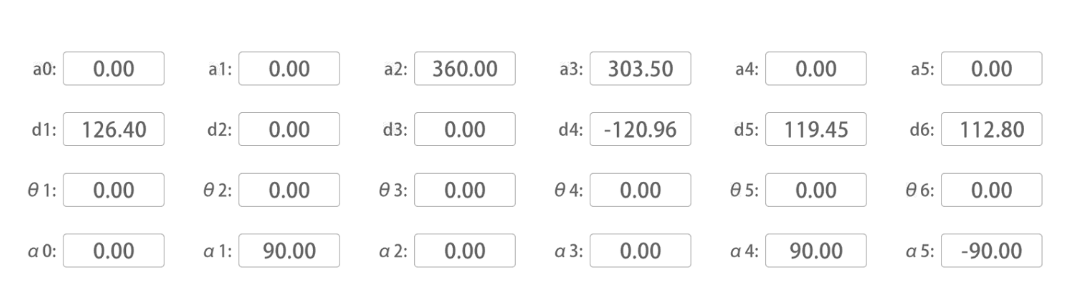

The following steps describe how to set the DH parameter.

-

After connecting to the robot, click the upper left logo icon 10 times, and then enter the password (default is JAKAAMAZING). The following interface will show up.

-

On the left side of Mech-Viz, right-click the robot name, select Open Robot File Directory, and then open the

xxxx_algo.jsonfile. -

Enter the [d1, a2, a3, d4, d5, d6] values in the above image to the dh field in the

xxxx_algo.jsonfile.Then, open and save thexxxx_algo.jsonfile. -

On the left side of Mech-Viz, right-click the robot name and select Reload Robot.

Due to the inability to adjust the shoulder_offset and elbow_offset values in the file of xxxx_algo.json.json, there may still be some errors in the robot’s motion.

-

-

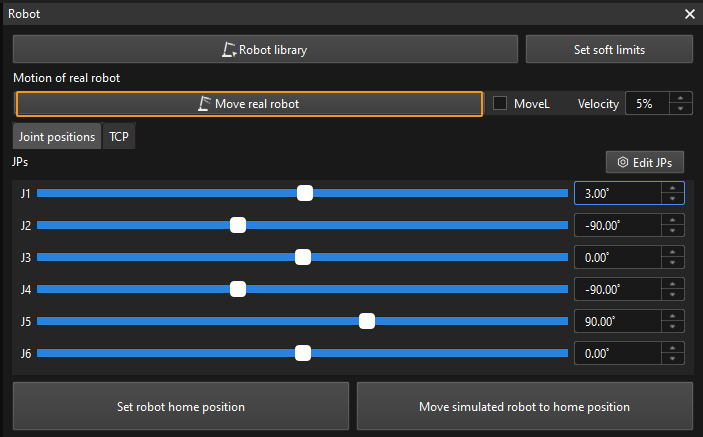

In the toolbar of Mech-Viz, change the “Vel.” (velocity) and “Acc.” (acceleration) parameters to 5%.

-

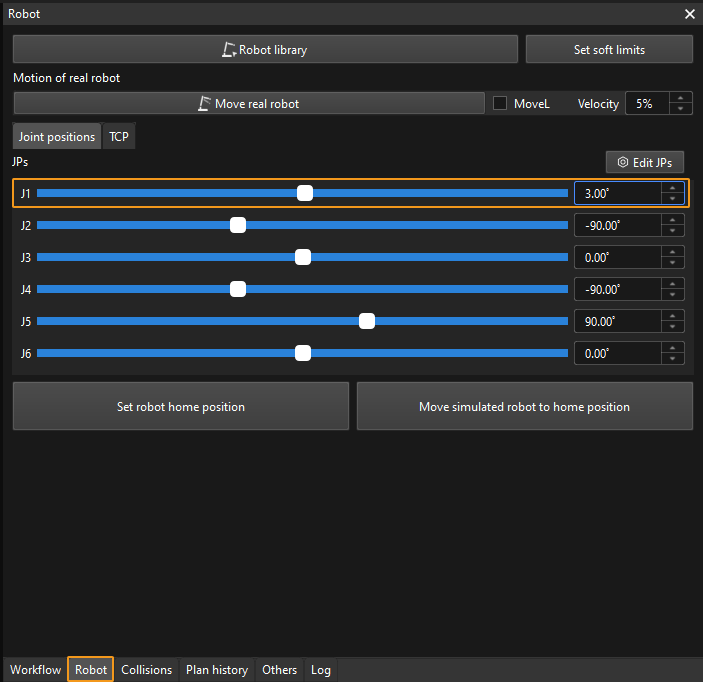

Click Sync Robot in the toolbar, and you can synchronize the poses of the simulated robot in the 3D simulation space with the poses of the real robot. Then click Sync Robot again to unselect it.

-

In the Robot tab, slightly adjust the value of “J1”, for example, from 0˚ to 3˚. This operation will move the simulated robot.

-

Click Move real robot and check if the real robot has moved. If the real robot has reached the JPs set for the simulated robot, the master-control communication is working.

When moving the robot, please ensure the safety of personnel. In the case of an emergency, press the emergency stop button on the teach pendant!