Set up Standard Interface Communication with ABB (RobotWare 7)

This guide shows how to load the Standard Interface program files to an ABB robot, and establish the Standard Interface communication between Mech-Mind Vision System and the robot.

| In this section, you will load the robot Standard Interface program and the configuration files to the robot system to establish the Standard Interface communication between the vision system and the robot. |

Preparation

Check Controller and Software Compatibility

-

Controller: OmniCore

-

Controller system software version: RobotWare 7.3 or above

Click here for instructions

-

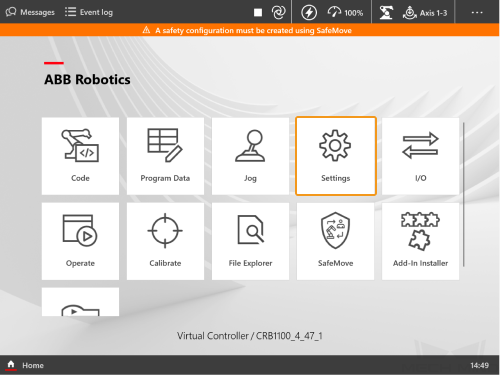

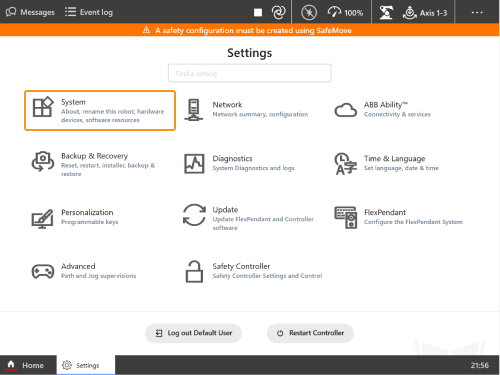

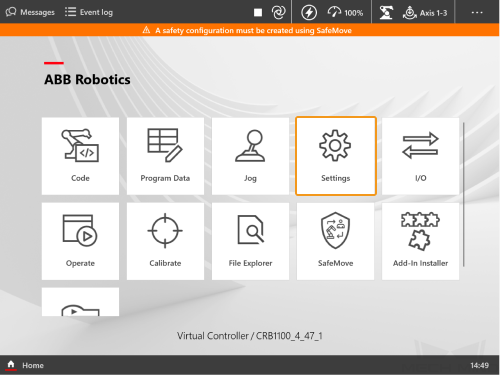

In the Home interface of the teach pendant, select .

-

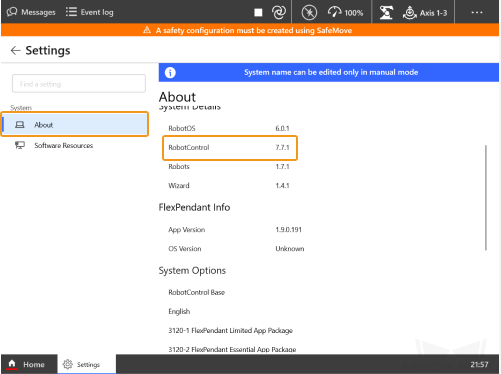

Click About. In the System Details section, check whether the RobotWare version is higher than 7.3.

-

| If the preceding conditions are not met, the vision system cannot communicate with the robot by using the Standard Interface. Contact the robot manufacturer for support. |

Set up the Network Connection

Connect the Hardware

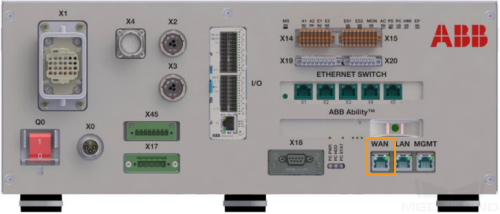

Plug one end of the Ethernet cable into the network port of the IPC and the other end into the WAN port of the robot controller. The following figure shows a sample WAN port.

| The Ethernet cable must be connected to the WAN port. |

Set IP Addresses

-

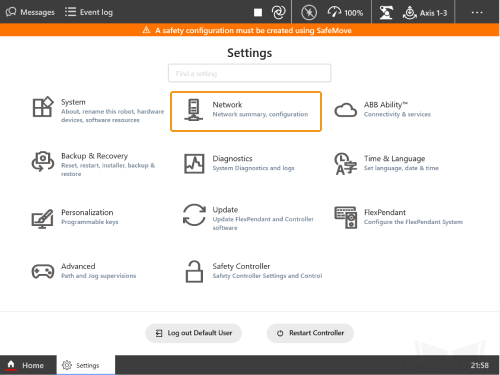

In the Home interface of the teach pendant, select .

-

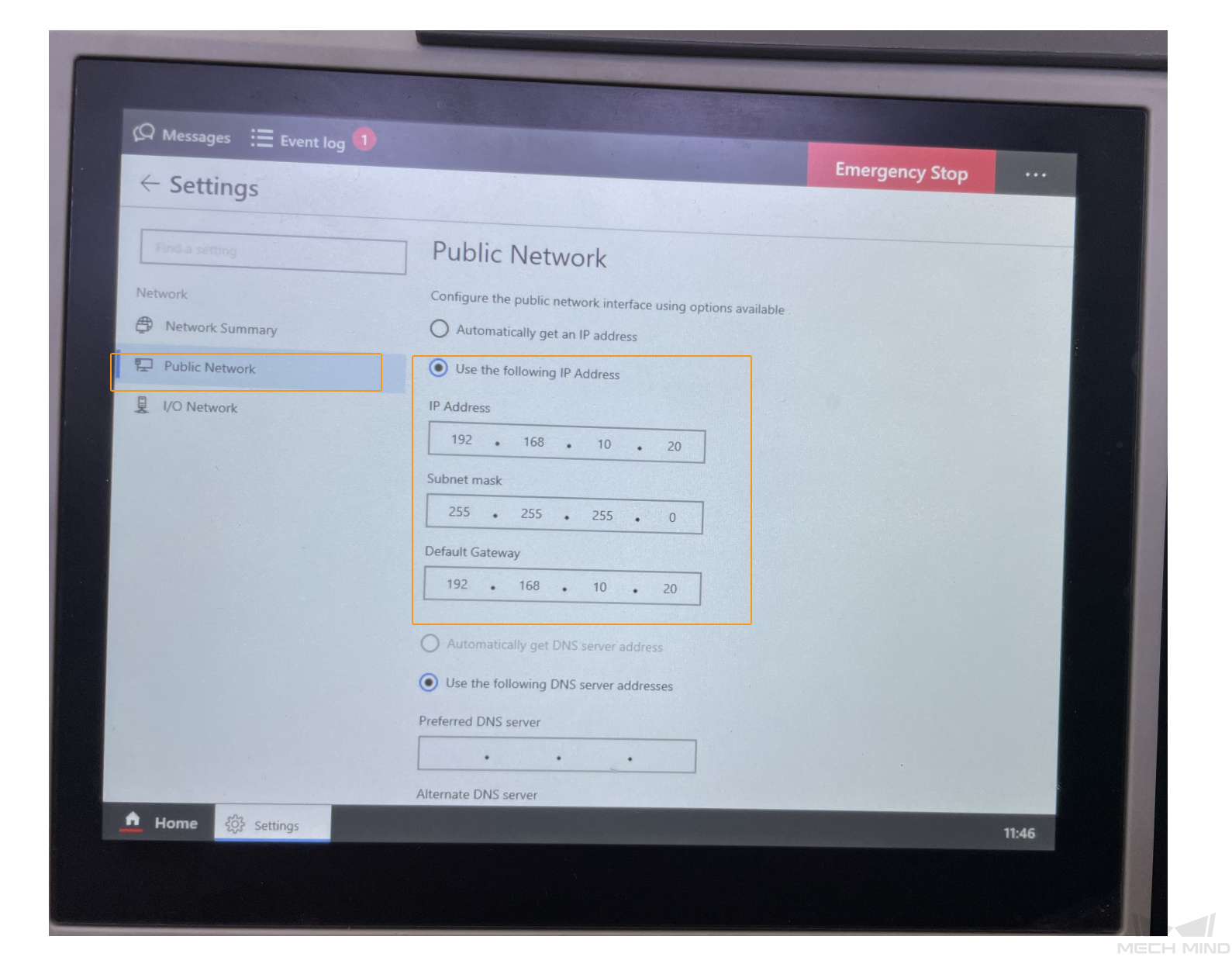

Click Public Network, select Use the following IP Address, and then set IP Address, Subnet mask, and Default Gateway.

When you set IP addresses, differentiate the IP address of the WAN port from the IP address of the LAN port. -

Set IP Addresses on the IPC

To allow communication between the IPC and the robot controller, the IP addresses of the IPC and robot controller must reside in the same subnet. This means that the network portions and subnet masks of the IP addresses should be the same. For example, 192.168.100.169/255.255.255.0 and 192.168.100.170/255.255.255.0 are in the same subnet.

Set up Robot Communication Configuration

-

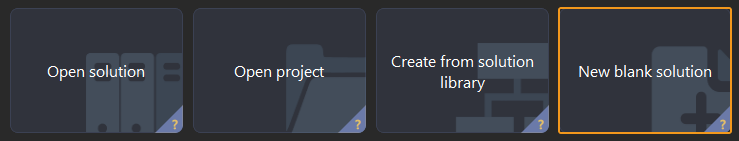

Run Mech-Vision, and you may enter different interfaces. Create a new solution according to the instructions below.

-

If you have entered the Welcome interface, click New blank solution.

-

If you have entered the main interface, click on the menu bar.

-

-

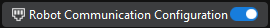

Click Robot Communication Configuration on the toolbar of Mech-Vision.

-

In the Robot Communication Configuration window, complete the following configurations.

-

Click the Select robot drop-down menu, and select Listed robot. Click Select robot model, and select the robot model that you use. Then, click Next.

-

In the Communication mode area, select Standard Interface for Interface service type, TCP Server for Protocol, and HEX (little-endian) for the protocol format.

-

It is recommended to set the port number to 50000 or above. Ensure that the port number is not occupied by another program.

-

(Optional) Select Auto enable interface service when opening the solution.

-

Click Apply.

-

-

On the main interface of Mech-Vision, make sure that the Robot Communication Configuration switch on the toolbar is flipped and has turned blue.

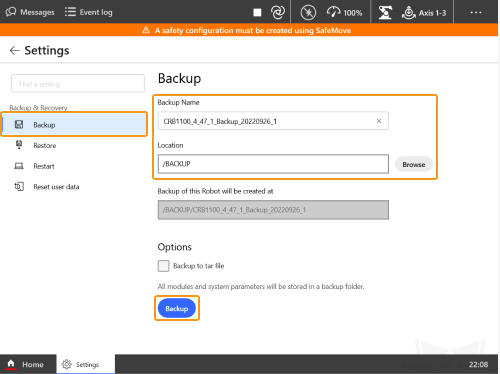

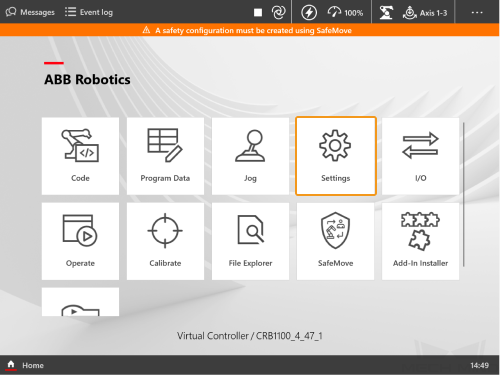

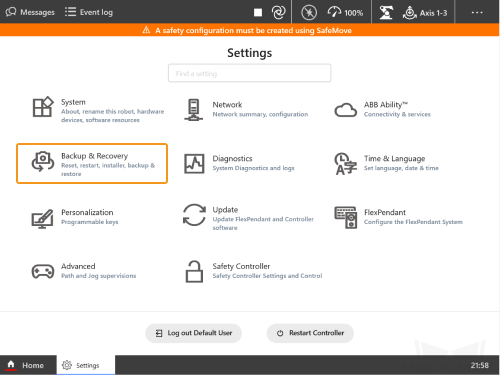

Backup

Back up the robot system before you operate the robot. This way, if any errors occurs, you can restore the robot system.

-

Plug the flash drive into the USB port on the back of the teach pendant.

-

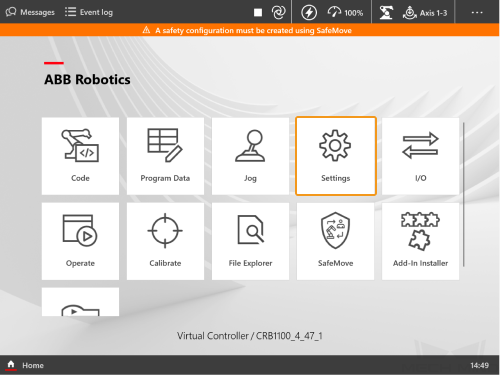

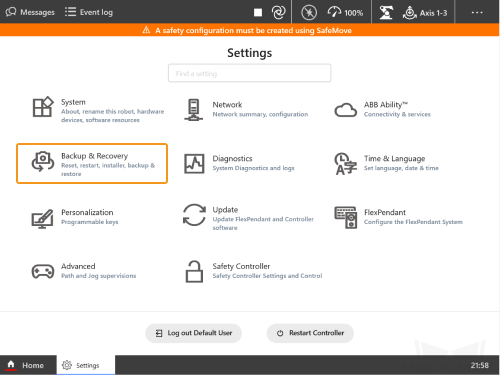

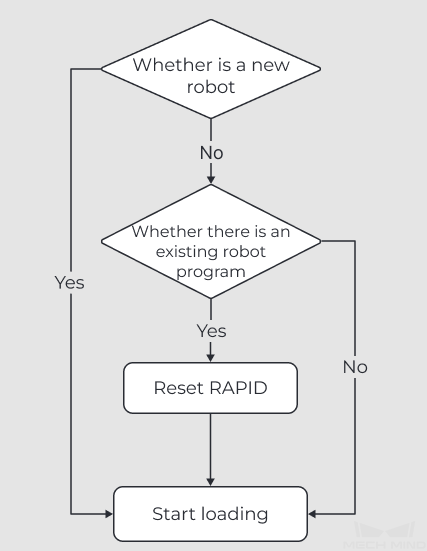

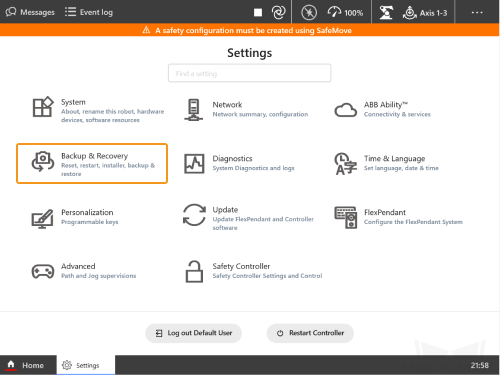

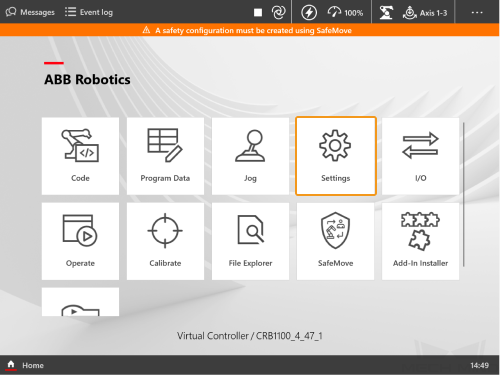

In the Home interface of the teach pendant, select .

-

Select Backup, reset Backup Name and Location, and then click Backup.

-

In the pop-up window, click OK to complete the backup process.

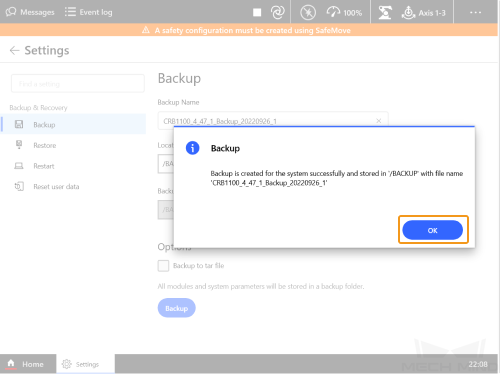

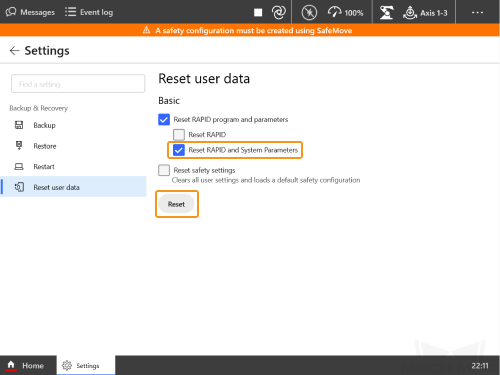

Resetting

Two types of resetting exist: resetting RAPID and resetting the system.

| If the master-control program is already loaded, perform this step to remove the master-control program. Do not use the master-control program together with Standard Interface. |

-

Resetting RAPID deletes the current RAPID program and data and retains system parameter settings.

Click here for instructions

-

Determine whether you need to reset RAPID based on the following flowchart.

-

In the Home interface of the teach pendant, select .

-

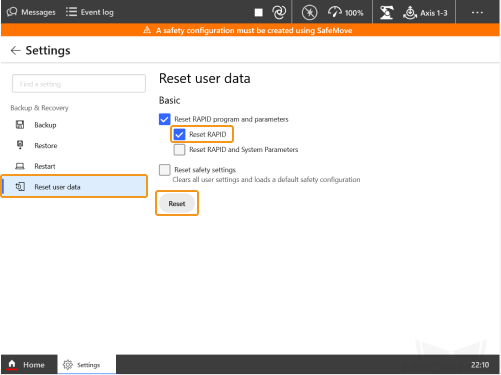

Select Reset user data in the left-side navigation pane, select Reset PAPID, and then click Reset.

-

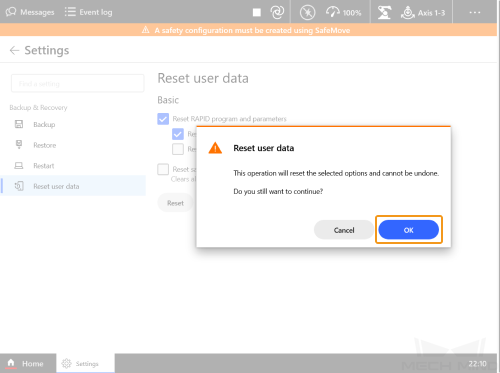

Select OK in the pop-up window.

-

-

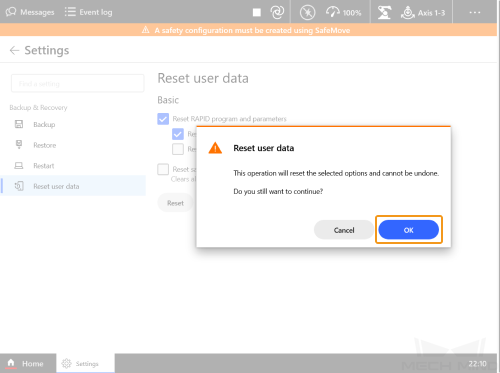

Resetting the system restores factory system settings and the PAPID program and resets I/O settings. If the PCIe card and other communication devices are configured, you must reconfigure them after you restart the system. Excise caution to select the resetting the system option.

Click here for instructions

-

In the Home interface of the teach pendant, select .

-

Click Reset user data in the left-side navigation pane, select Reset PAPID and System Parameters, and then click Reset.

-

Select OK in the pop-up window.

-

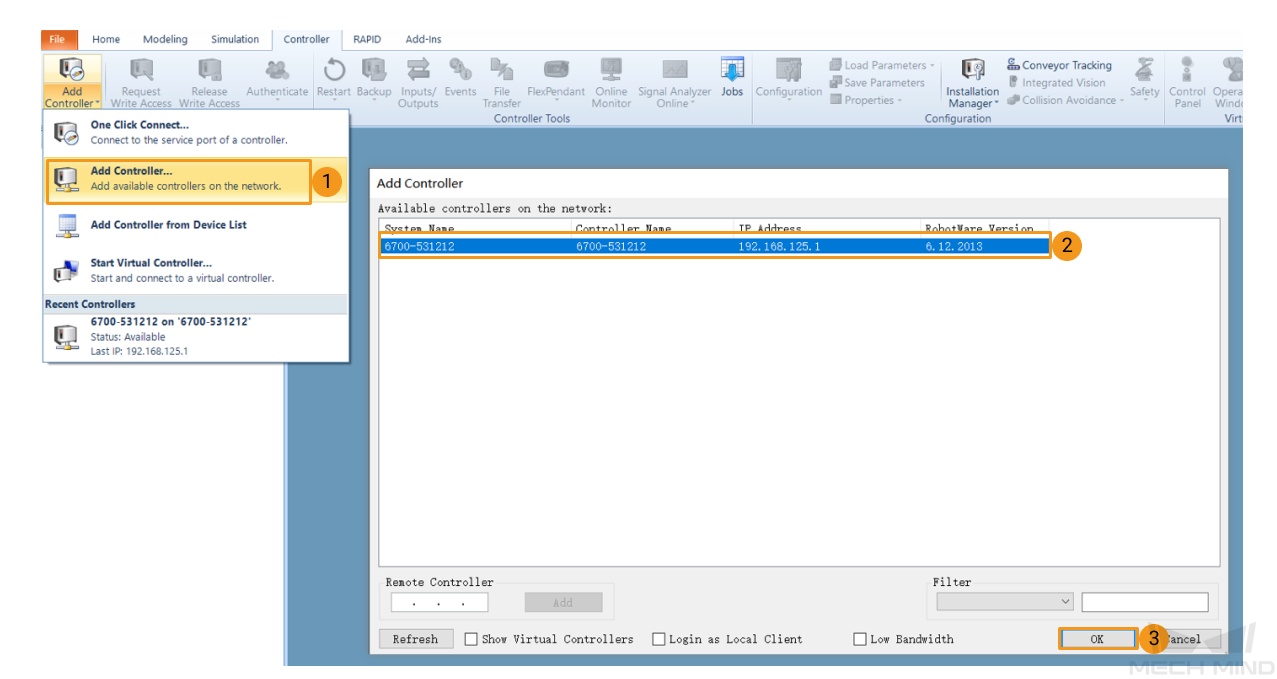

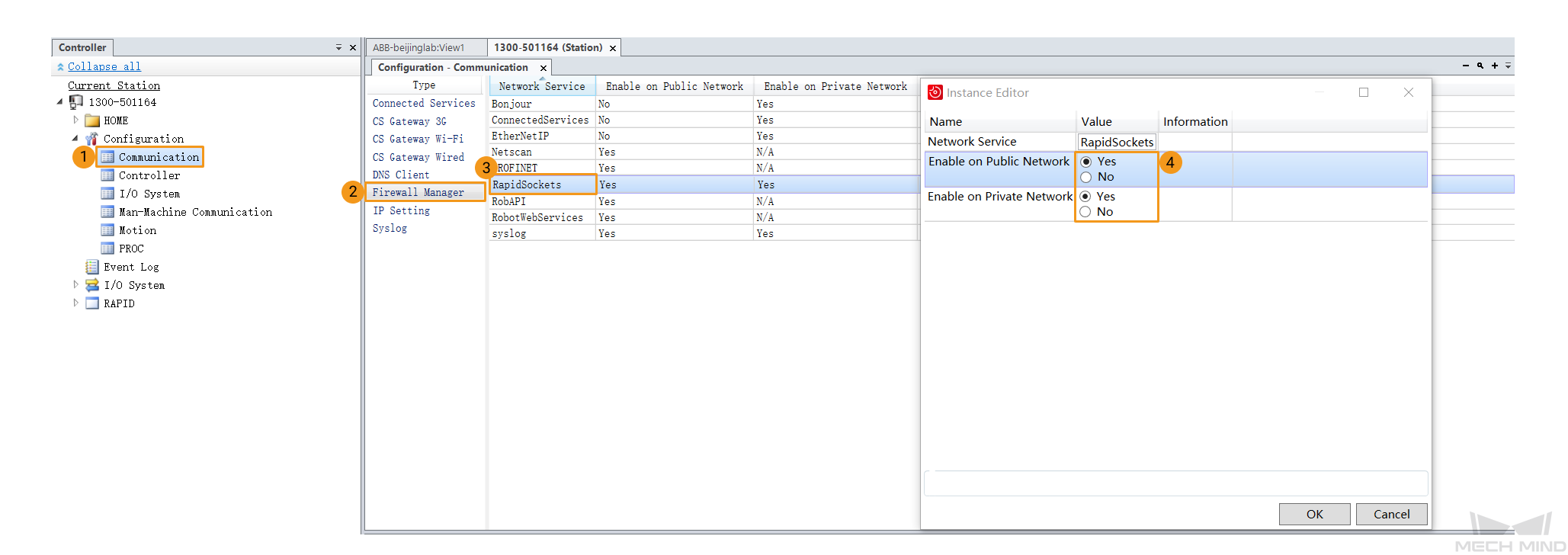

Enable the RapidSockets Network Service

-

The Ethernet cable is connected to the WAN port of the controller. To add the controller, you can open RobotStudio, click Add Controller, and then select the controller and click OK. After the controller is added, the controller management port will be connected automatically.

-

Follow the steps as shown in the figure below to enable the RapidSockets network service.

-

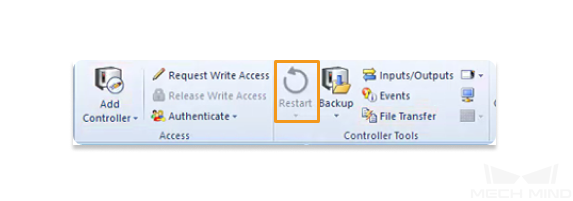

Click Restart to restart the controller. The mortifications take effect only after the controller is restarted.

Prepare Program Files

-

Plug the flash drive into a USB port on the IPC or another computer.

-

Download the

ABB.zipfile by clicking download program files and decompress the file. -

Go to the decompressed

ABBfolder and copy all files in the folder to the flash drive.The files must be MODX files.

Load the Program Files to the Robot

-

Plug the flash drive into the USB port on the back of the teach pendant.

-

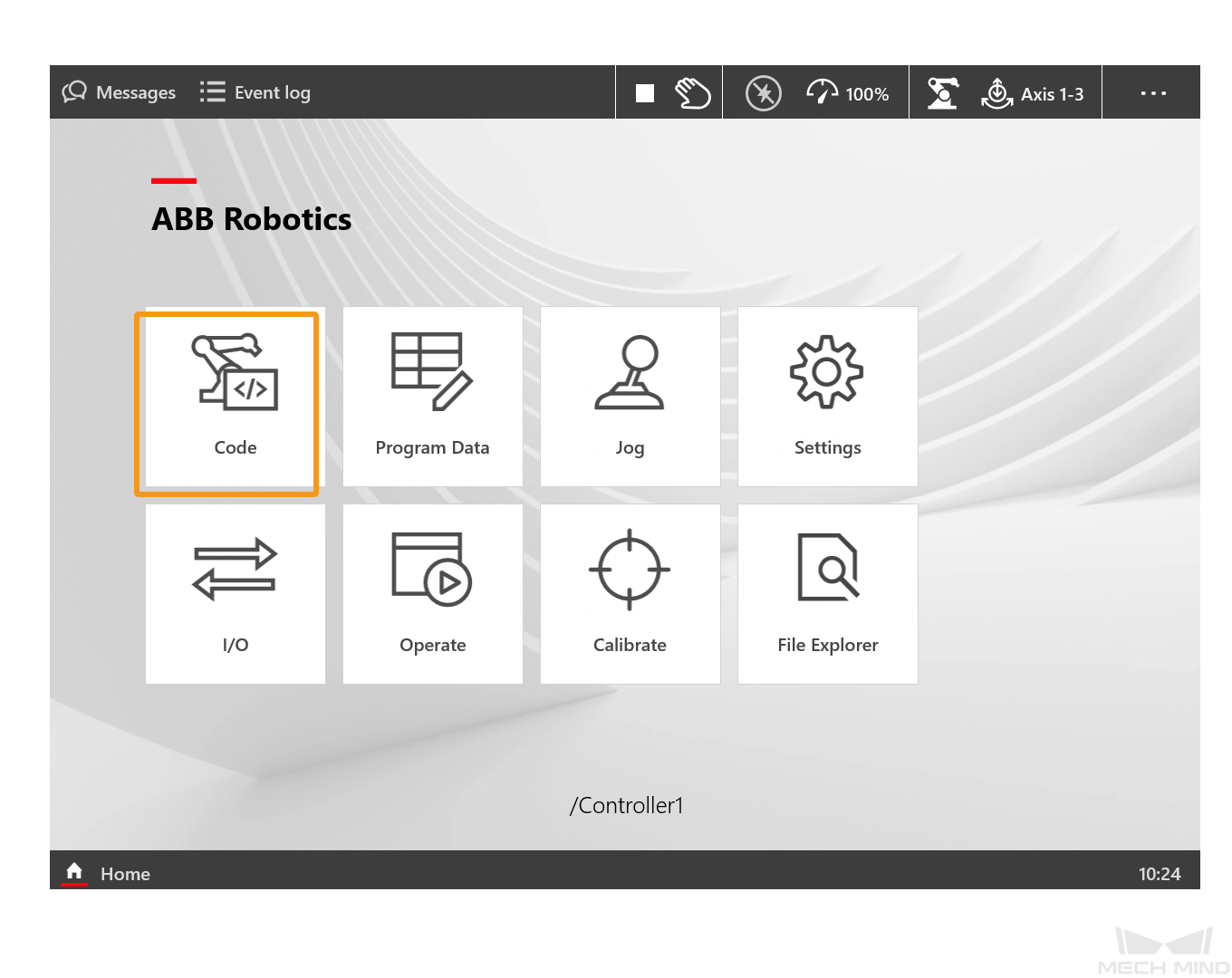

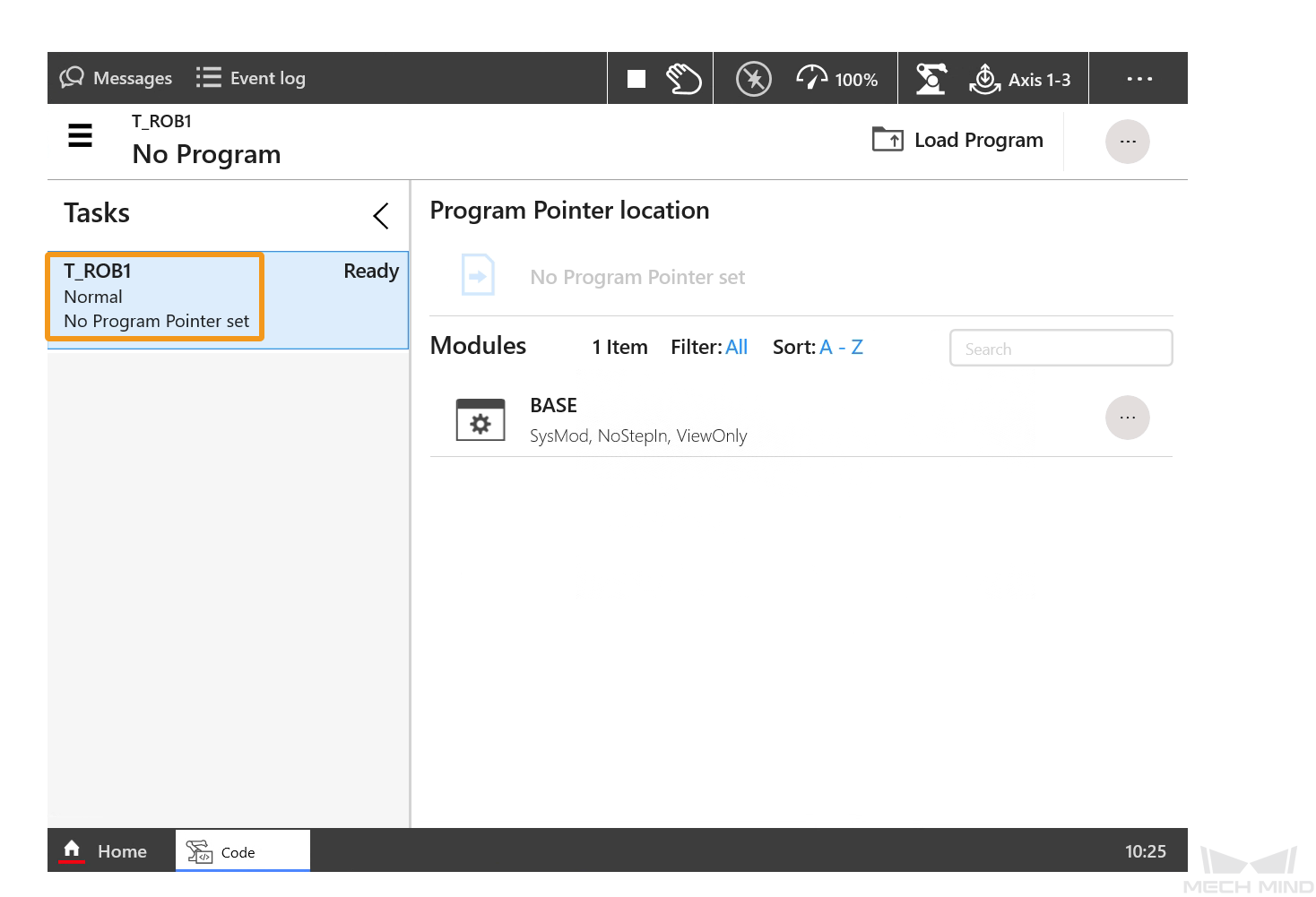

In the Home interface of the teach pendant, click Code.

-

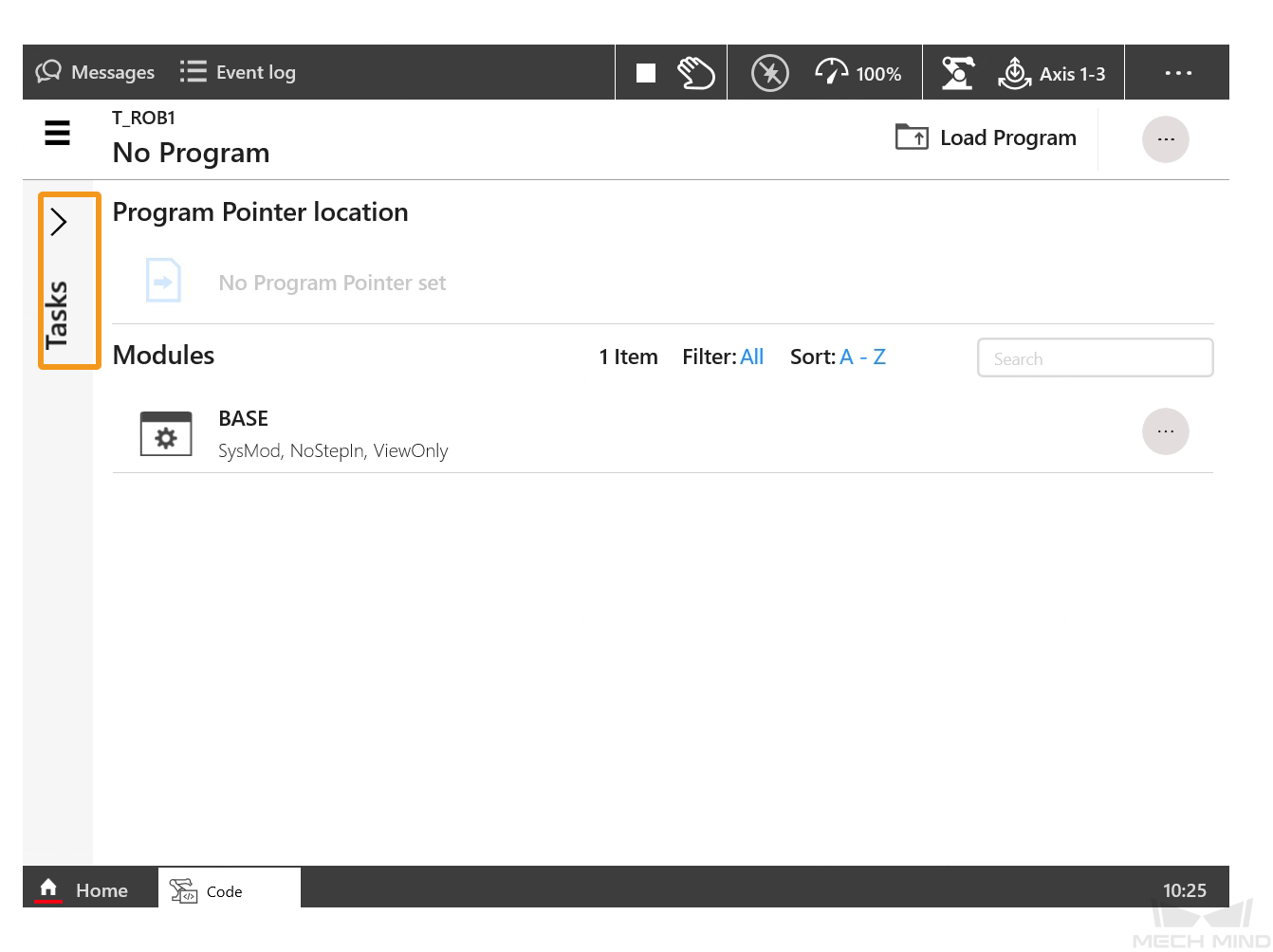

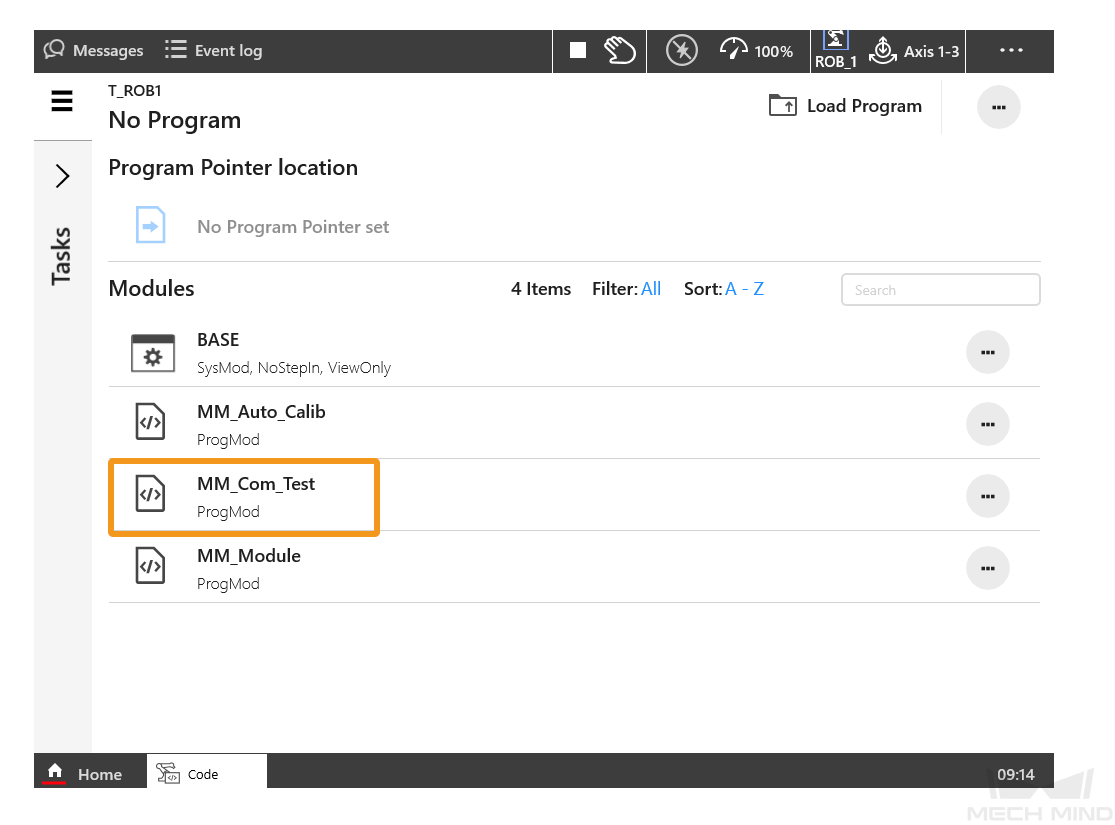

Click Tasks. In the pop-up Tasks panel, select T_ROB1.

-

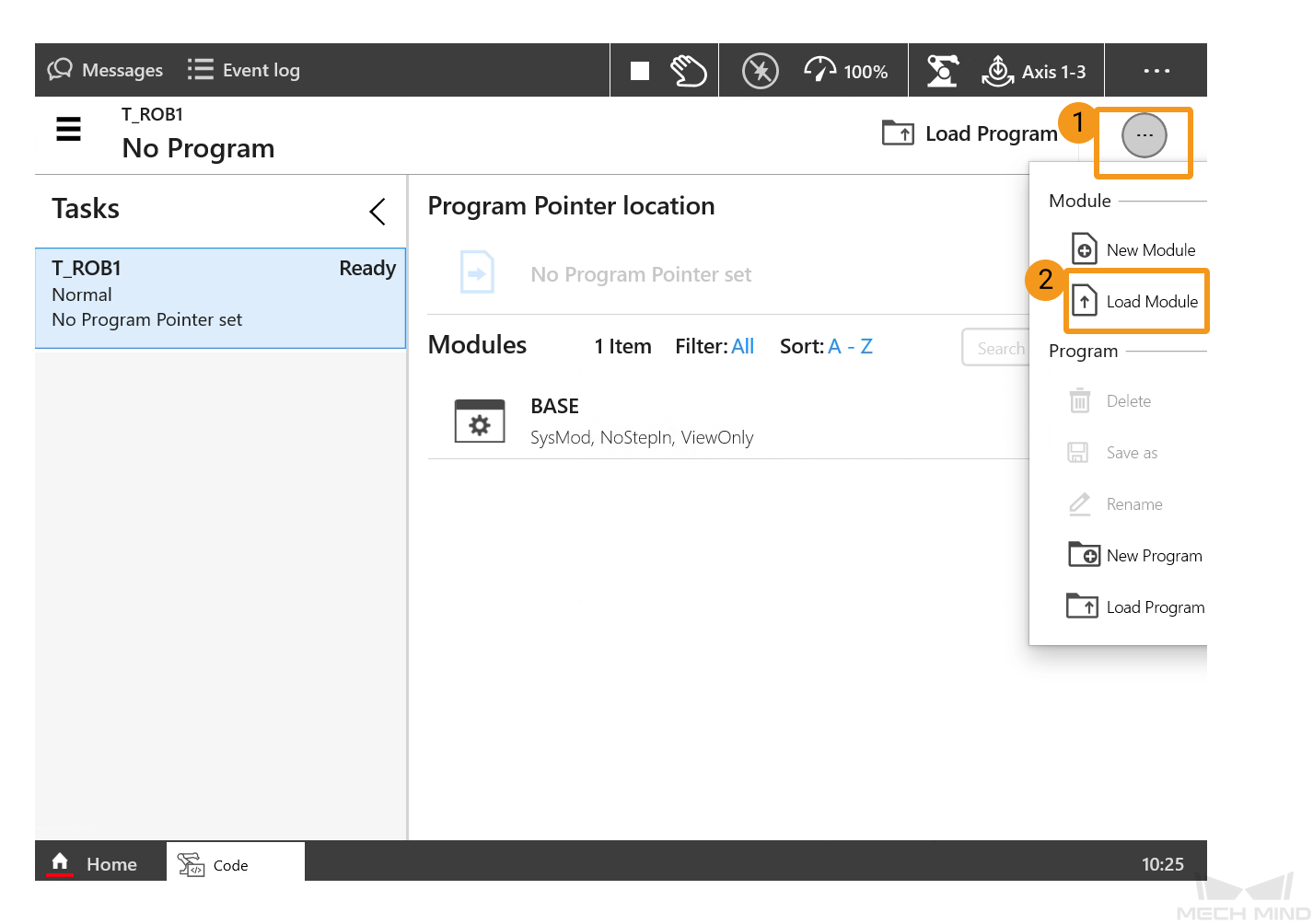

Click the menu in the upper-right corner and then click Load Module.

-

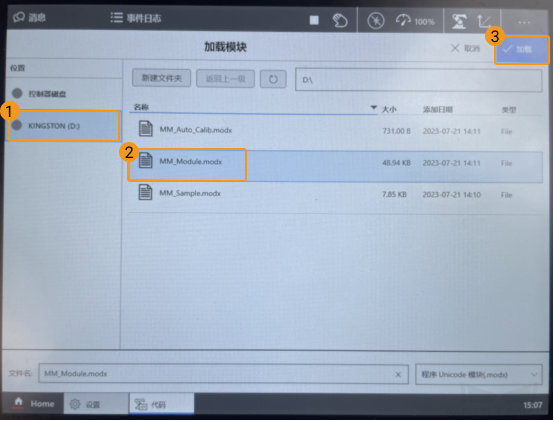

Click KINGSTON(D:), select

MM_Module.modxfrom the flash drive files, and then click Load.In this example, KINGSTON is displayed as a part of the flash drive name. This is because a Kingston flash drive is used. If you use a flash drive of another brand, the band name is displayed as a part of the flash drive name.

-

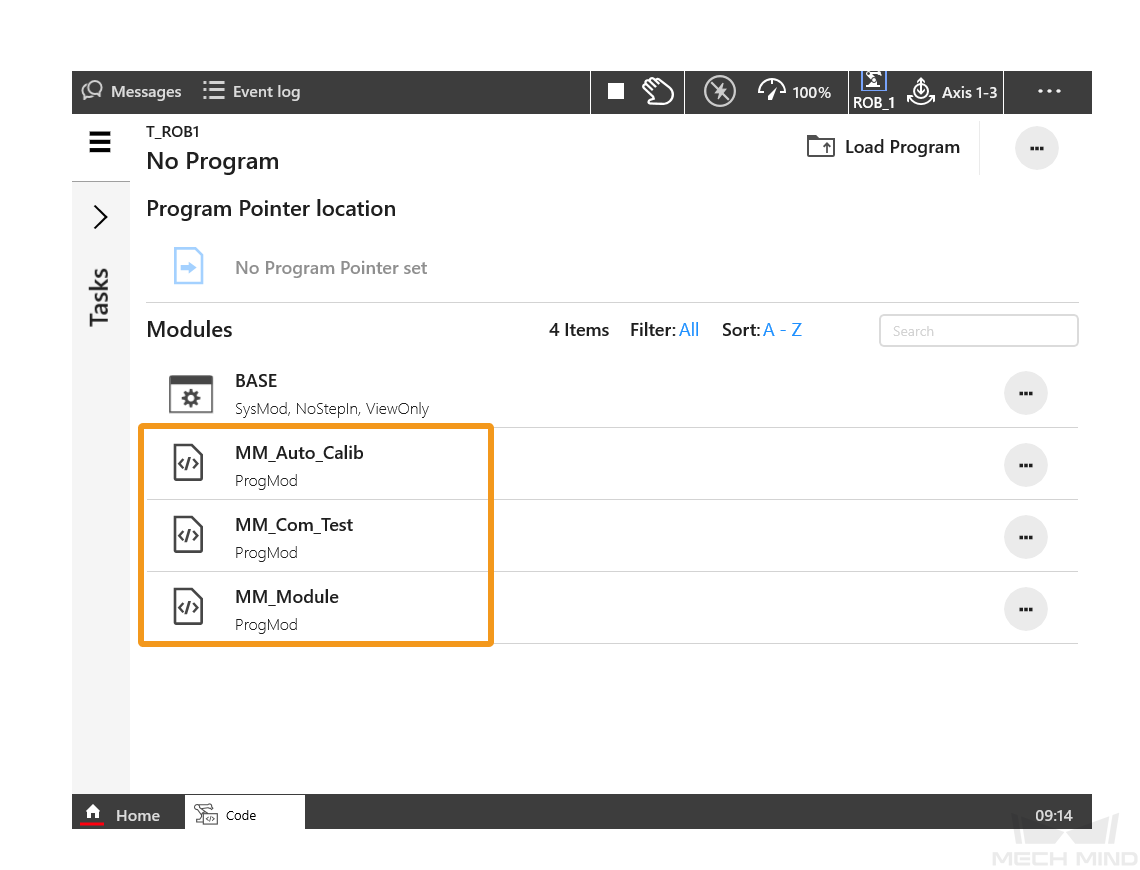

Repeat the preceding steps to copy

MM_Auto_Calib.modxandMM_Com_Test.modxto the robot system. The following figure shows the interface after all three files are loaded.

Test Standard Interface Communication

Select and Modify the Program Used for the Communication Test

-

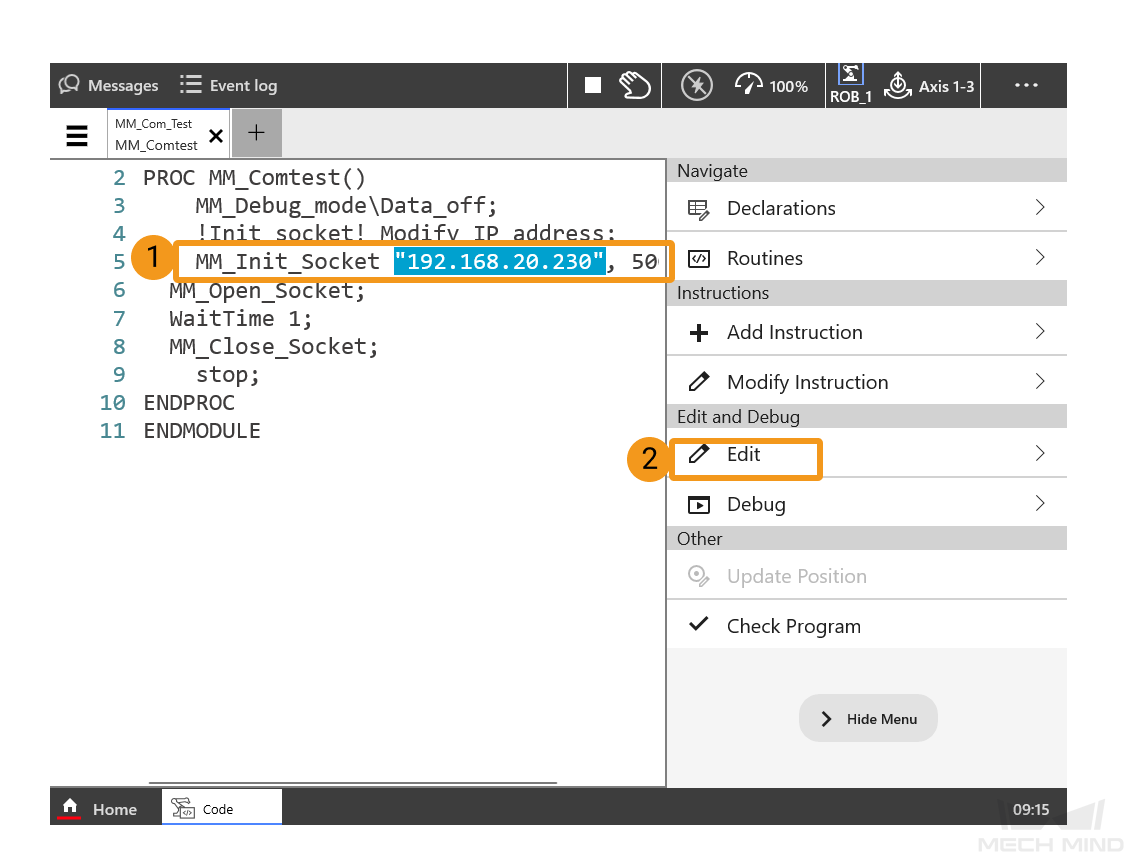

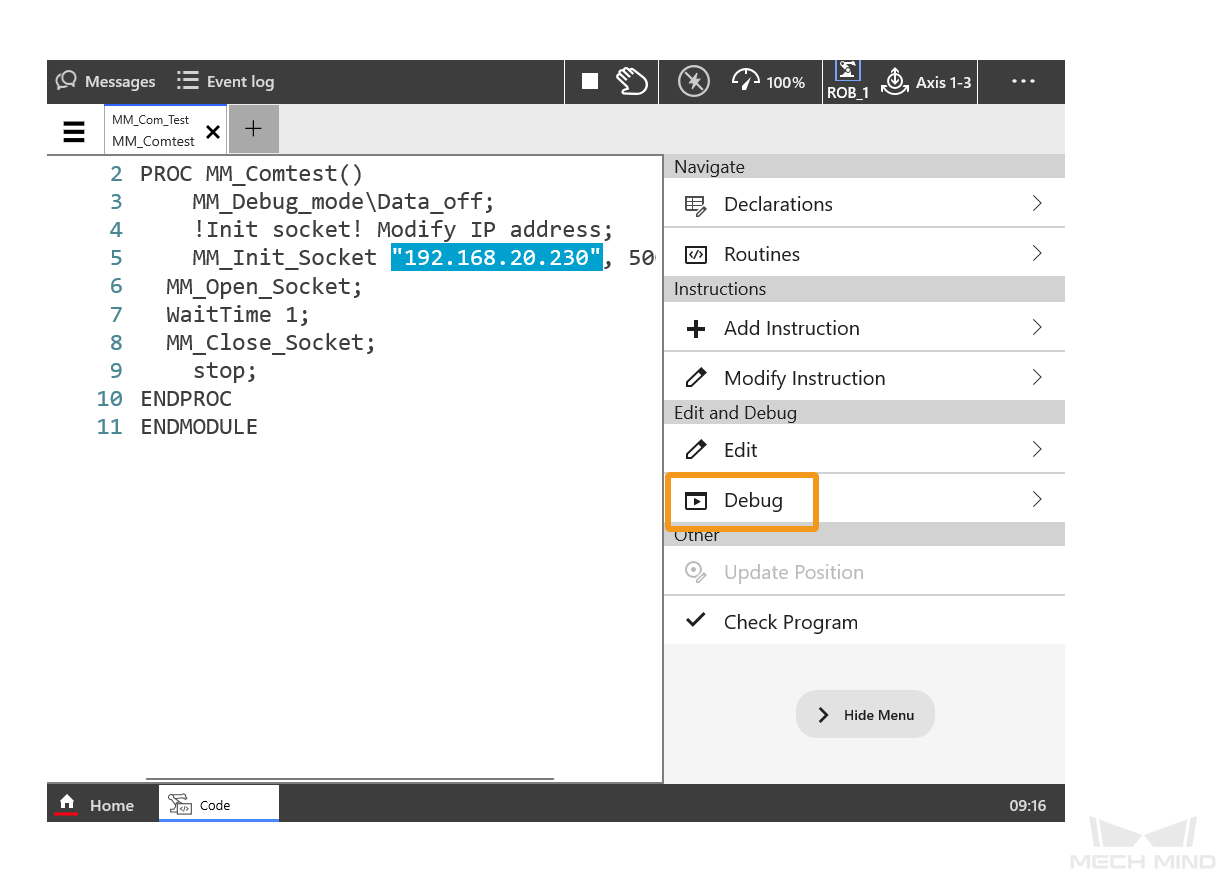

In the code interface, double-click MM_Com_Test.

-

Double-click the IP address of the program and click Edit to change the IP address into the IP address of the IPC. If the host port number set in Mech-Vision is modified, the port number 50000 here should be changed to the host port number in Mech-Vision.

Run the Program and Test Connection

-

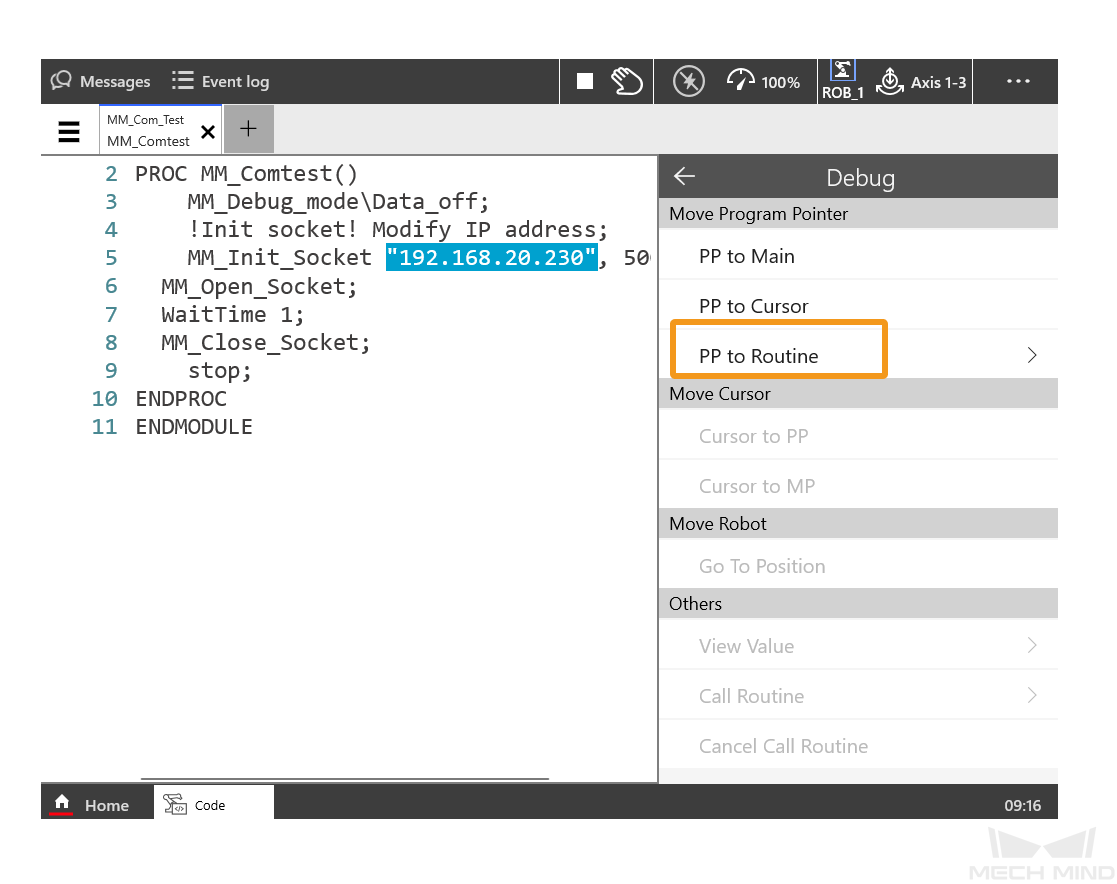

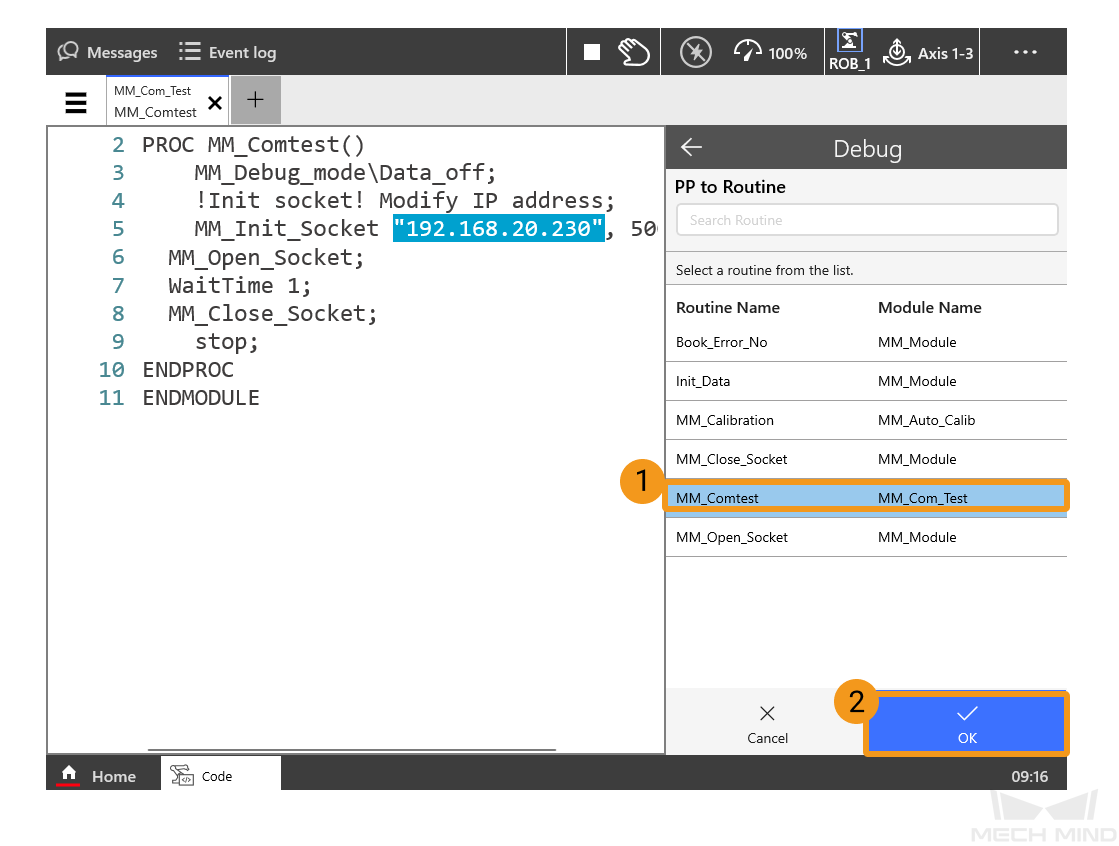

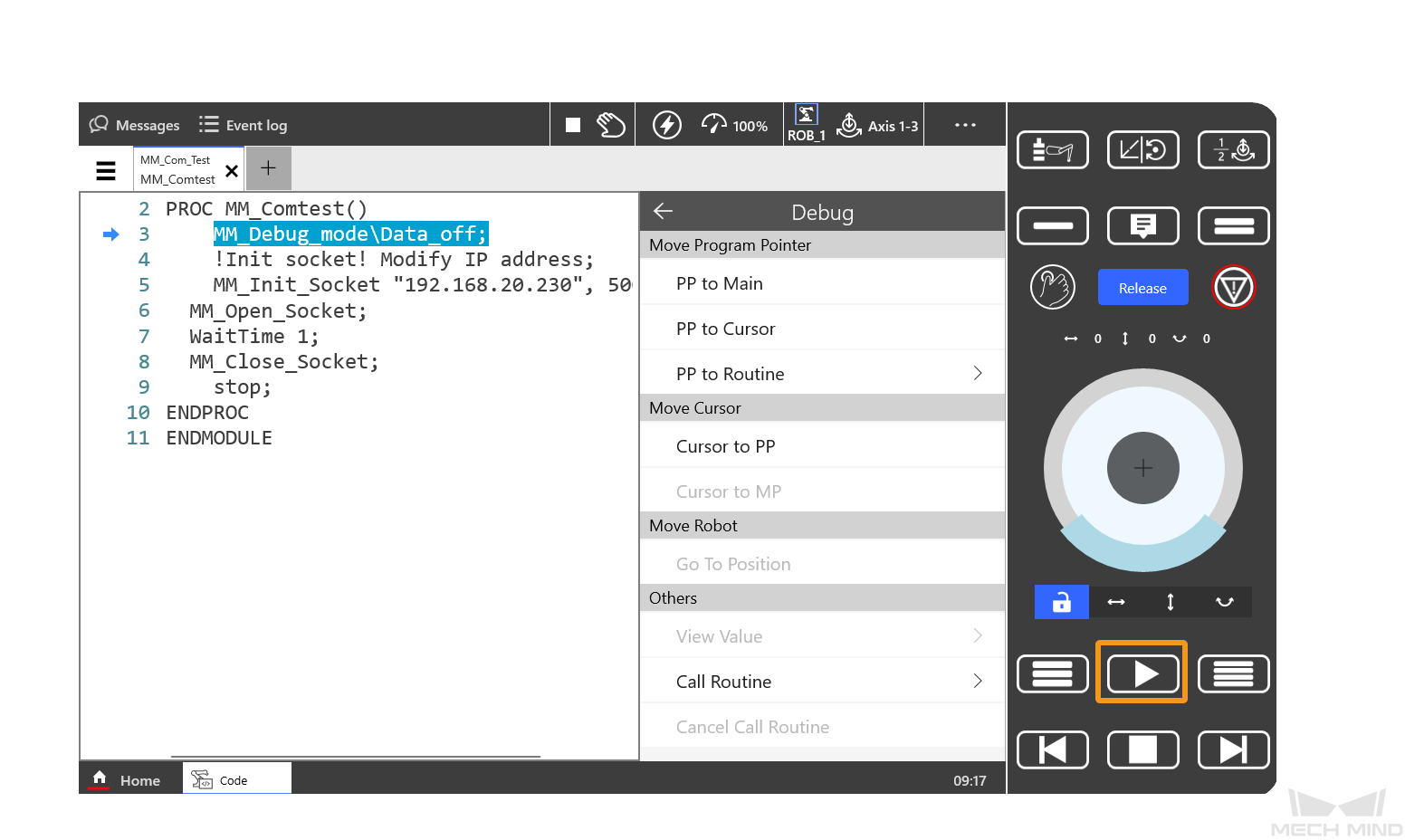

In the following interface, select .

-

Confirm that MM_Comtest is selected and click OK.

-

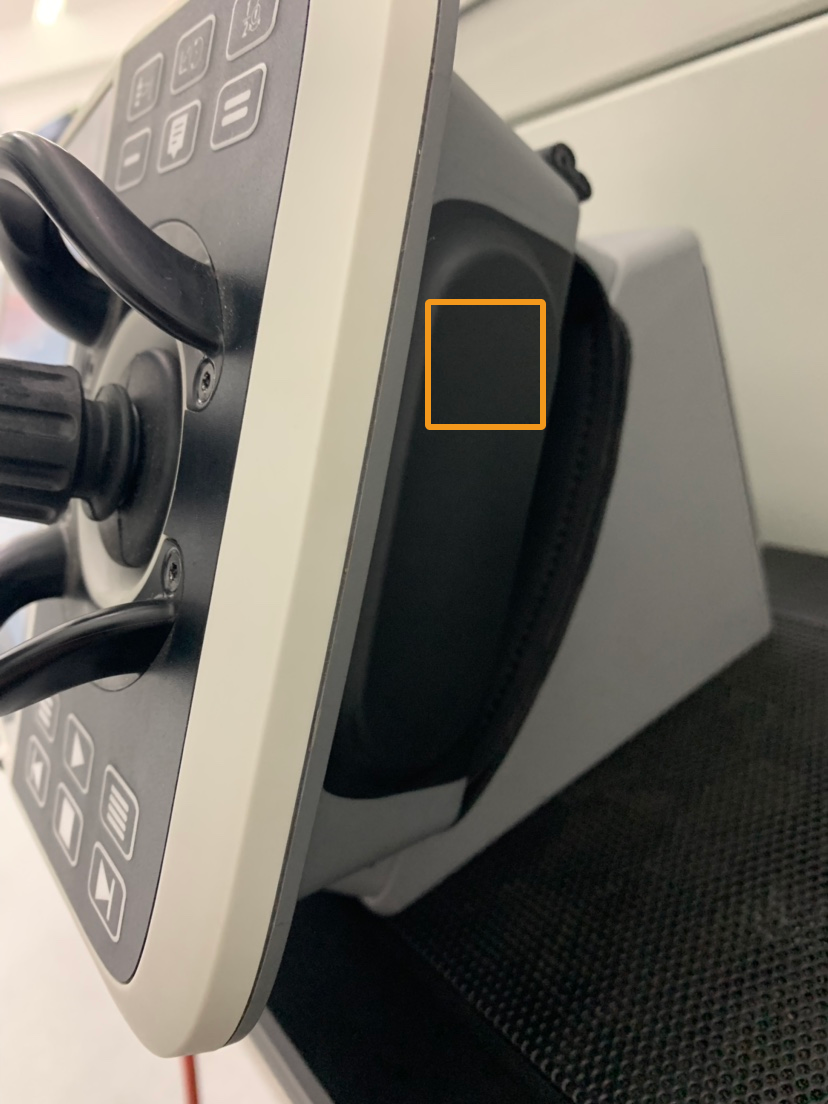

Press and hold the following button to power up the motor. In this case, the status icon on the teach pendant indicates that the motor is powered up.

-

Click the run button on the teach pendant.

-

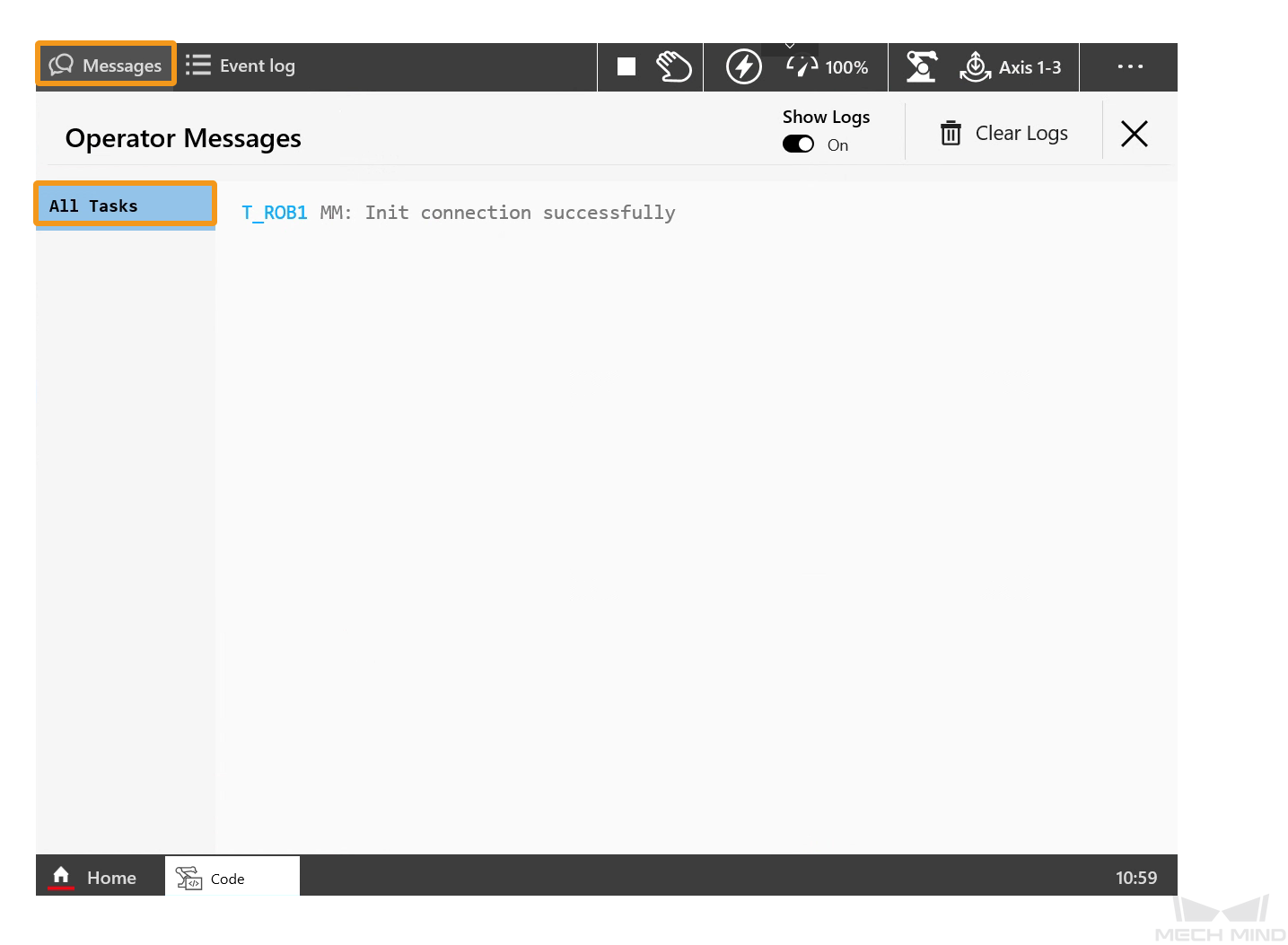

Click Messages in the upper-left corner and select All Tasks. The following message is displayed.

-

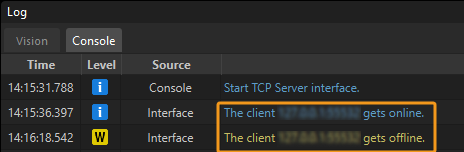

If the communication between the robot and the vision system is set up, a log will be recorded on the Console tab of the Log panel of Mech-Vision.

Troubleshooting

If the program has been loaded but the robot cannot be connected successfully, please check whether the following requirements have been met.

-

IPC side:

-

The firewall is turned off.

-

The IPC can communicate with the robot IP address with the ping command in the command prompt.

-

There is no interference from any antivirus software.

-

Two network ports of the IPC belong to different subnets and there is no conflict.

-

If the IPC is connected via a router, there is no interference from other network cables.

-

-

Robot side:

-

The Ethernet cable is connected to the WAN port of the controller properly.

-

The robot IP address is set correctly. Please ensure that the set IP address is that of the WAN port instead of others.

-

You have run the program on the robot side.

-

Confirm that the robot firewall allows network communication.

-