Risk Assessment and Fixes

During the deployment of the solution, there will be several risks, and this section will evaluate the possible risks and provide corresponding fixes.

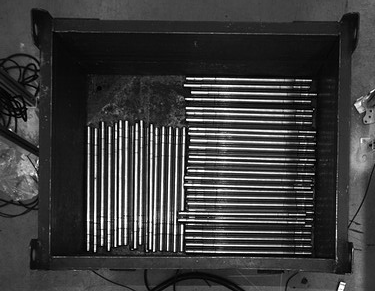

The Shafts Are Too Long

-

Risk: When the length of the shaft is beyond the field of view of the camera, the camera can only identify one end or the center of the shaft and cannot obtain the point cloud of the complete shaft. Under this circumstance, it is difficult to accurately obtain the center position of the shaft in the axial direction.

-

Fix: For scenarios where the placement accuracy in the length direction is high, auxiliary devices such as cylinders can be used to make the ends of the shafts aligned.

Adhesion of Other Substances on Workpiece Surface

-

Risk: The incoming workpieces have significant oil stains and iron filings on the surface, making it easy for the magnetic gripper to lose grip.

-

Fix:

-

Use claw grippers or other robot tools.

-

Before using the magnetic gripper, clean the iron filings and oil stains on the surface of the shaft.

-

Reflective Shafts

-

Risk: The shafts with reflective surfaces are more susceptible to the influence of external light, resulting in the partial loss of the obtained shaft point cloud, which affects the success rate of vision recognition and locating accuracy.

-

Fix: Build a shading or take other shading measures, such as applying shading film, to provide a stable lighting environment for the camera, so as to improve the quality of the point cloud obtained. For detailed instructions, refer to Shading Solution.

Partitions of Transparent Material

-

Risk: The partitions are made of highly transparent material, allowing the camera to easily recognize the lower-level workpieces through the partitions.

-

Fix: Use non-transparent or frosted partitions.

Low Rigidity of Partitions

-

Risk: The low rigidity of partitions leads to the following problems during actual usage.

-

The partitions are prone to deformation, causing grippers unable to lift them.

-

After the gripper picks the partition, the partition may easily fall.

-

-

Fix: Use partitions of high-strength materials or add reinforcement bars to the partition to enhance the strength of the partitions.

Reflective Bin Walls

-

Risk: The inner walls of the bin are reflective, showing the reflection of the shafts, which will cause more noise in the shaft point cloud and misidentifications by deep learning.

-

Fix: It is recommended to replace the bin or make the inner walls of the bin non-reflective.

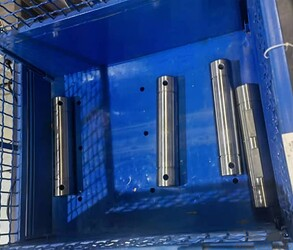

Low Rigidity of Bin Walls

-

Risk: The bin walls are welded by iron mesh, and the following problems are encountered in actual use.

-

After long-term use, the bin walls are seriously deformed (convex or concave), which brings great difficulty to picking.

-

The point clouds on the upper edge of the bin walls are sparse, making it difficult to accurately locate the bin when the bin pose is updated dynamically.

-

-

Fix: The bin walls should be made of square steel or other high-strength materials, and should be constantly checked and maintained during later use.

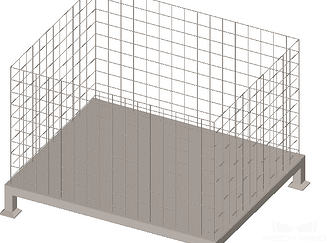

Mesh Bin Walls

-

Risk: The spaces in the bin wall are larger than the cross-sectional area of the shaft, and the shaft can easily stick out of the bin and cannot be picked.

-

Fix: Use a bin with sealed bin walls.

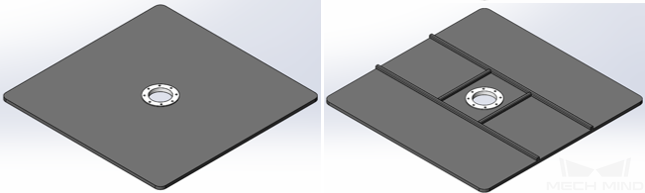

Smooth Bottom Surface of the Bin

-

Risk: The bottom surface of the bin is smooth and flat, and the shafts are prone to roll through the bin. After the camera captures the images and the shaft poses are calculated, the actual positions of the shafts may change due to rolling, making it difficult for the robot to pick accurately.

-

Fix: Place high-friction pads or other materials that can serve the same function on the bottom surface of the bin.

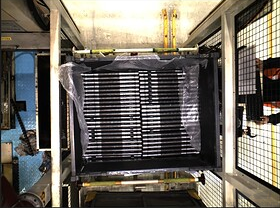

The Film in the Bin Obscures the Shaft

-

Risk: When there is film attached to the inner walls of the bin, the film may obscure the shaft, resulting in the shaft not being recognized, or the clamp collides with the film during robot picking, so that the shaft cannot be picked accurately.

-

Fix: Remove the film, and change to other packaging forms or unify the conditions of incoming workpieces to ensure that the film in the bin does not obscure the workpiece.

Reflective Shafts with Random Incoming Orientations

-

Risk: For reflective shafts incoming in an orderly manner, the angle between the axis direction of the shaft and the structured light direction of the camera is random. When the axis direction of the shaft is parallel to the structured light direction of the camera, the point cloud quality obtained by the camera is the worst, which affects the success rate and locating accuracy of vision recognition.

-

Fix:

-

It is recommended to unify the orientations of the incoming shafts into one direction.

-

Use a dual-camera solution, and the two cameras are mounted perpendicular to each other so that the field of view can cover the entire bin.

-

Deformed Bin

-

Risk: Serious deformation of the bin will lead to difficulty in bin identification, and collisions are prone to occur when the shaft is picked.

-

Fix: Limit the allowable degree of deformation of the bin in the technical agreement.

Insufficient Locating Accuracy and Stability of the Slide Rail

-

Risk:

-

In applications where the camera is mounted on a moving rail, the low repeatability of the rail positioning may cause the extrinsic parameters of the camera to change, resulting in inaccurate robot picking.

-

In applications where the camera is mounted on a moving rail, the instability of the rail can affect the camera, leading to changes in both its intrinsic and extrinsic parameters, consequently causing inaccuracies in object recognition and picking.

-

-

Fix:

-

It is highly recommended that the camera be mounted on a moving rail with high repeatability. Also, the motion should be slowed down as much as possible while satisfying the cycle time.

-

It is recommended to install two or more cameras in a fixed position to avoid the risk of camera movement described above.

-

Weak Magnetic Suction Force

-

Risk: When using magnetic grippers to pick up workpieces such as shafts (excluding non-ferromagnetic workpieces such as stainless steel), there is a potential risk that the suction force will decrease and the shaft will fall off due to the small contact area.

-

Solution: The magnetic gripper can be designed as a V-shaped structure to expand the contact area between the gripper and the shaft, and it is suitable for picking shafts of various diameters.