Basics

This section introduces the basic information about the single-case carton depalletizing solution, including the applicability, unsupported functions and technical specifications.

Applicability

This section introduces the applicability of the single-case carton depalletizing solution from the aspects of carton types, project requirements, carton surface features, etc.

Carton Types

The table below illustrates the solution’s applicability to carton types.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

Regular paper cartons with a standard rectangular upper surface. |

|

Flattened irregular rectangular cardboard, waste cartons, etc. |

|

Project Requirements

The table below illustrates the solution’s applicability to project requirements.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

Single-Case Carton Depalletizing |

|

Mixed-Case Carton Depalletizing |

|

Single-Case Carton Palletizing |

|

Mixed-Case Carton Palletizing |

|

Pick one box at a time, pick multiple boxes at a time, pick an entire row at a time, pick one layer at a time, pick as many boxes as possible at a time, divide the vacuum gripper into sections, etc. |

Customize picking rules or quantity. |

Carton Surface Features

The table below illustrates the solution’s applicability to carton surface features.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

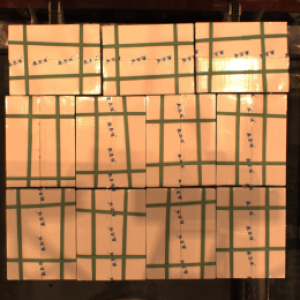

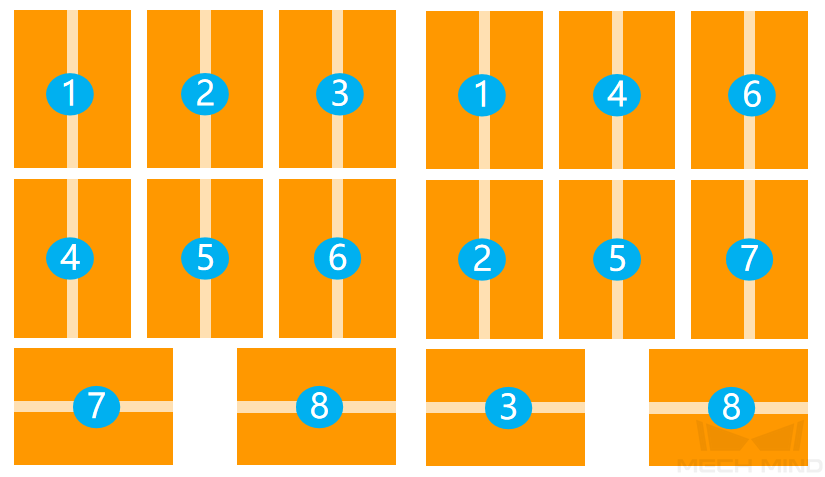

Carton edges are clear. The carton’s surface can be either a single color or plain, , and it can feature patterns, text, strapping, or tapes. |

|

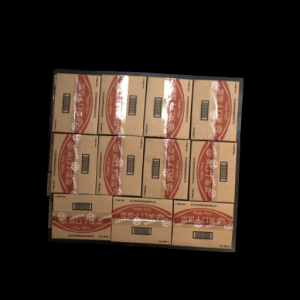

Unable to clearly distinguish whether the cartons are single or multiple. For example, the carton body is divided by distinct patterns or stripes, or the cartons are closely packed together. |

|

Carton Placement

The table below illustrates the solution’s applicability to carton placement.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

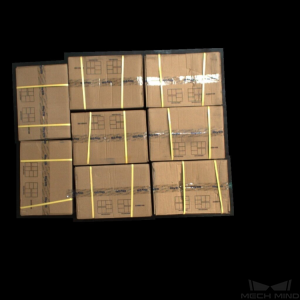

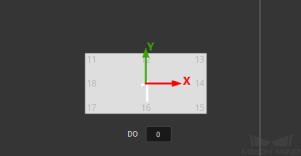

Individual carton sizes are moderate, that is, each carton occupies an appropriate proportion within the camera’s field of view. |

|

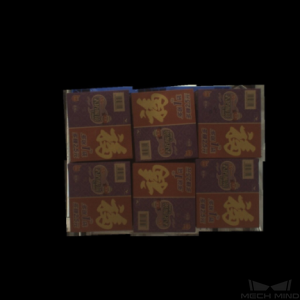

Individual carton sizes are excessively large, with each carton occupying the entire camera field of view, which could potentially impact the effectiveness of deep learning recognition. |

|

The camera is horizontally placed within the camera’s field of view, and the angle between the carton and the camera ranges from 0° to 45°. |

|

The camera is inclined within the camera’s field of view, and the angle between the carton and the camera is greater than 45°. This may lead to deep learning recognition errors. |

|

Object Carriers

The table below illustrates the solution’s applicability to object carriers.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

Cartons are placed on a pallet. |

|

Cartons are placed in four-wall bins, containers, or turnover boxes, or there are other obstructions around the carton pallet. |

|

Vacuum Gripper Design

The table below illustrates the solution’s applicability to vacuum gripper design.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

Single-section vacuum gripper |

|

Multi-row, multi-section vacuum gripper |

|

Single-row, multi-section vacuum gripper |

|

Dimensions

The table below illustrates the solution’s applicability to carton dimensions.

| Feasible | Not feasible |

|---|---|

Ensure the dimensions of the real carton input to the software are accurate. |

Not applicable for cartons with unknown dimensions. |

Sorting Methods for Carton Poses

The table below illustrates the solution’s applicability to sorting methods for carton poses.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

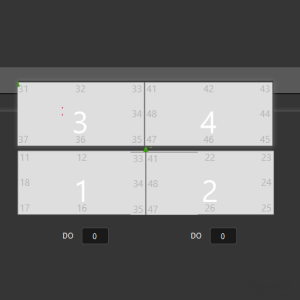

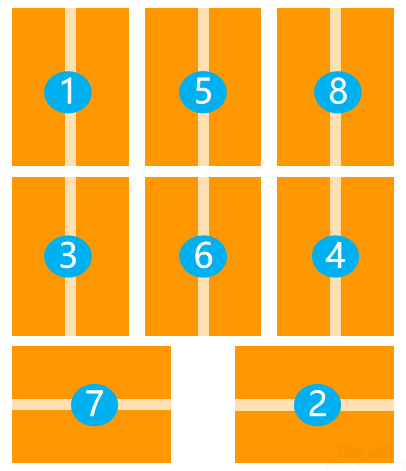

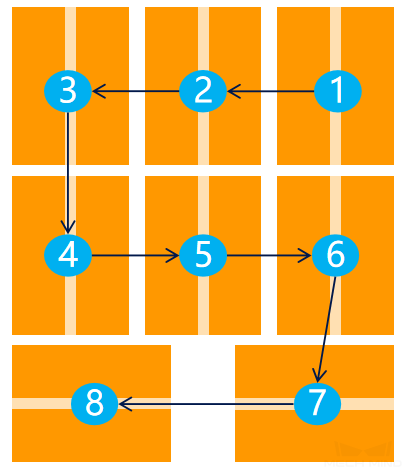

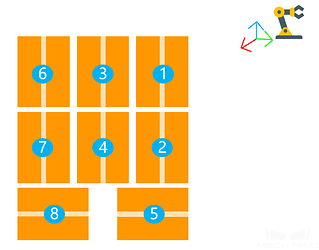

Sort by rows/columns. |

|

Custom sorting by pallet pattern, gripper picking method, etc. |

|

Sort by S shape on plane. |

|

||

Sort by the horizontal and vertical distance from the carton to the robot base. |

|

Carton Orientation during Picking/Placing

The table below illustrates the solution’s applicability to carton orientations during picking/placing.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

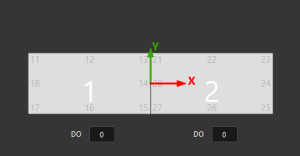

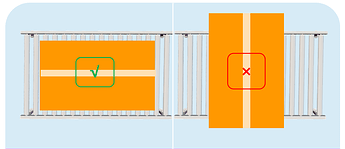

When the conveyor belt is too narrow, the carton should be placed in the center, and the carton’s long side should align with the direction where the conveyor belt moves. |

|

|

|

Collision Detection

The table below illustrates the solution’s applicability to collision detections.

| Feasible | Not feasible |

|---|---|

|

Detect collisions between objects with dynamically changing shapes, such as highly flexible dresspacks or dynamic robot tools that may be switched during picking. |

Unsupported Functions

The single-case carton depalletizing solution does not support the following functions.

-

Identification of the carton orientation. When the difference between the length and width of the carton is less than 20 mm, this solution does not support the identification of the carton’s orientation.

-

Identification of the carton dimensions. When the carton is deformed, the vision recognition accuracy will be affected. Generally, the identification of carton dimensions is completed by the scanning equipment.

-

Detection of damage on the carton’s surface. This solution does not currently support the defect detection function.

Technical Specifications

The technical specifications for the single-case carton depalletizing solution are as follows.

-

Positioning accuracy: ±5 mm

-

Recognition success rate: more than 99%

-

Execution time of vision system: within 4 s