Basics

This section introduces the basic information about the single-case sack depalletizing solution, including the applicability, unsupported functions, and technical specifications.

Applicability

The applicability of the single-case sack depalletizing solution can be described from the aspects of sack types, project requirements, sack surface features, etc.

Sack Types

The table below illustrates the solution’s applicability to sack types.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

Neatly arranged woven bags, sacks, paper bags, etc. These sacks should have a nearly rectangular upper surface as in the case of ordinary plastic woven bags and kraft paper bags. |

|

Randomly stacked, transparent, or overly small bags, such as snack bags and saline bags. |

|

Project Requirements

The table below illustrates the solution’s applicability to project requirements.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

Single-case sack depalletizing |

|

Multi-case sack depalletizing |

|

Sack Surface Features

The table below illustrates the solution’s applicability to sack surface features.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

The edges of the sacks are clear so that they can be distinguished by deep learning. The sacks can be colored or monochromatic or have patterns or texts on their surface. |

|

The edges of the sacks are not clear so they cannot be distinguished by deep learning. The sacks have complex surface patterns or are closely placed or stacked together, which may lead to unstable recognition performance. |

|

Sack Placement

The table below illustrates the solution’s applicability to sack placement.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

The sack is placed horizontally in the camera’s field of view, with a tilt angle of 0° to 45°. |

|

The sack is placed at an angle of greater than 45° in the camera’s field of view. This may lead to wrong deep learning–based recognition results. |

|

Workobject Carriers

The table below illustrates the solution’s applicability to workobject carriers.

| Feasible | Illustration | Not feasible | Illustration |

|---|---|---|---|

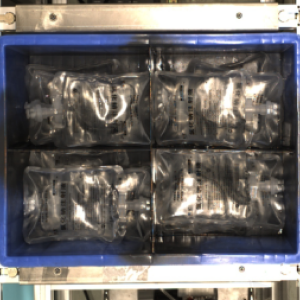

Sacks placed on a pallet |

|

Sacks placed in a stack rack |

|

Dimensions

The table below illustrates the solution’s applicability to sack dimensions.

| Feasible | Not feasible |

|---|---|

Because Mech-Vision requires the actual dimensions of the sacks to be input, only sacks with known dimensions can be recognized. |

Because Mech-Vision requires actual sack dimensions to prevent incorrect recognition by deep learning, sacks with unknown dimensions are not suitable for recognition. |

Unsupported Functions

The single-case sack depalletizing solution does not support the following functions:

-

Recognition of sack fronts and backs, sack orientations, and sack models. If you need to implement this function, there should be noticeable differences between the front and back features and differences in diverse orientation features and model features of the sacks. On this basis, it is necessary to obtain the color image of a single sack first and then use the object detection model to distinguish between the front and back of the sack and recognize the orientation of the sack mouth and the model of the sack.

-

Recognition and grasping of the pallet. In addition to this solution, you need to build a pallet recognition project so as to achieve this purpose.

-

Capturing a single image to achieve the picking of multiple objects with a dual gripper. For this function, it is essential to first recognize all the topmost sacks, perform a specific sorting of sack poses, and then send all the sack poses to the robot.

-

Recognition of sack pallet patterns. For this function, it is necessary to identify all sacks in the top layer and define the possible pallet patterns beforehand. Then the pallet pattern can be determined according to the poses of the topmost sacks.

-

Recognition of sack specifications. Sacks can hardly have a fixed shape, which may affect the vision recognition accuracy.

Technical Specifications

The technical specifications for the single-case sack depalletizing solution are as follows.

-

Positioning accuracy: ±20 mm

-

Recognition success rate: more than 99%

-

Execution time of vision system: within 4 s