Data Acquisition Examples

This topic provides data acquisition examples for some algorithm modules, demonstrating how to acquire high-quality datasets in practical applications.

Instance Segmentation

-

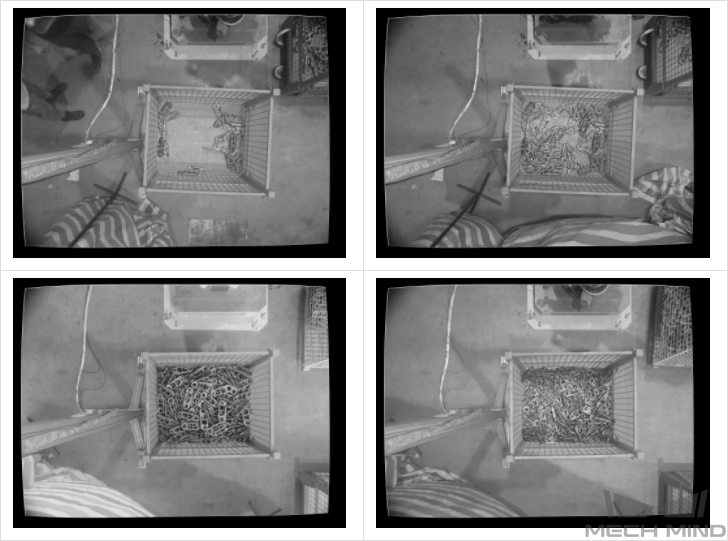

A metal piece project involves objects of a single class, and thus 50 images were acquired. Object placement conditions of lying down and standing on the side need to be considered. Object positions at the bin center, edges, corners, and at different heights need to be considered. Object positional relationships of overlapping and parallel arrangement need to be considered. Samples of the acquired images are as follows:

-

A grocery project involves seven classes of mixing objects, which requires classification. The objects of one class placed in different orientations and mixing objects of multiple classes need to be considered to fully capture object features. Number of images for objects of one class = 5 × number of object classes. Number of images for mixing objects of multiple classes = 20 × number of object classes. The objects may come lying flat, standing on sides, or reclining, so images containing all faces of the objects need to be considered. The objects may be in the center, on the edges, and in the corners of the bins. The objects may be placed parallelly or fitted together. Samples of the acquired images are as follows:

-

Placed alone

-

Mixedly placed

-

-

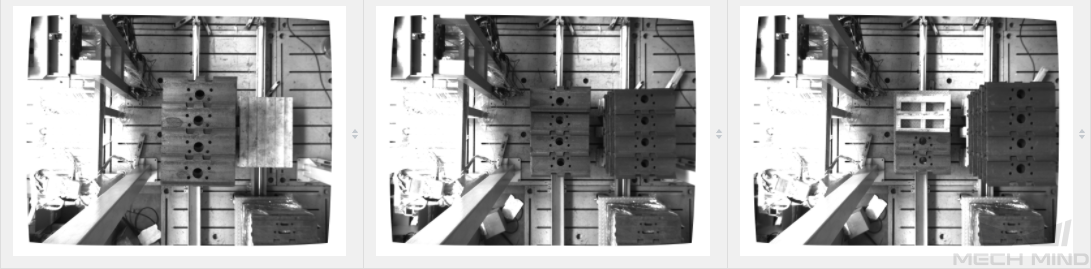

A track shoe project involves track shoes of many models, and thus the number of images acquired was 30 multiplied by the number of models. The track shoes only face up, so only the facing-up condition needs to be considered. They may be on different heights under the camera. In addition, they are arranged regularly together, so the situation of closely fitting together needs to be considered. Samples of the acquired images are as follows:

-

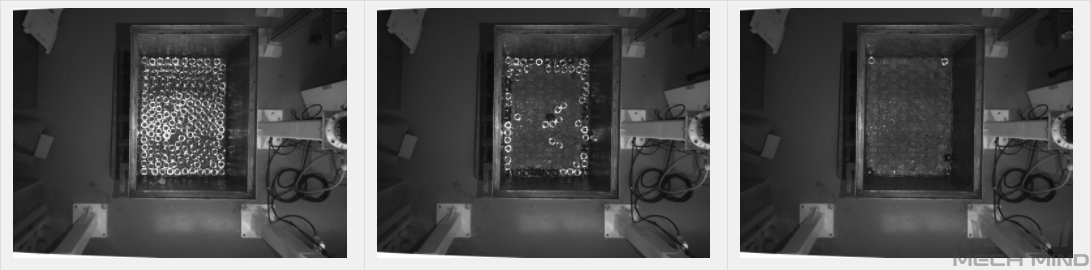

A metal piece project involves metal pieces presented in one layer only, and thus, only 50 images were acquired. The metal pieces only face up. They are in the center, edges, and corners of the bin. In addition, they may be fitted closely together. Samples of the acquired images are as follows:

-

A metal piece project involves metal pieces neatly placed in multiple layers, and thus, 30 images were acquired. The metal pieces only face up. They are in the center, edges, and corners of the bin and are at different heights under the camera. In addition, they may be fitted closely together. Samples of the acquired images are as follows:

Classification

-

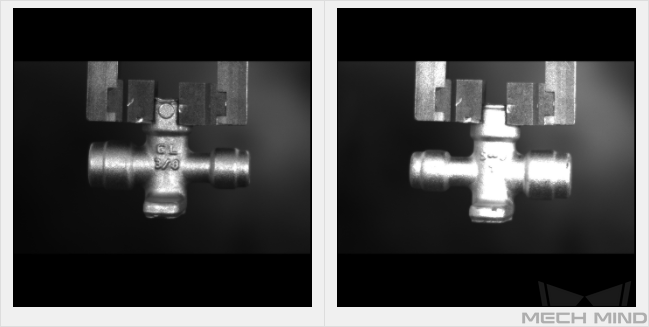

A valve tube project: Single object class. Distinguishing between the front and back sides of the valve tubes is needed. Positions are generally fixed with small deviations. Fifteen images for the front and back sides each were acquired.

-

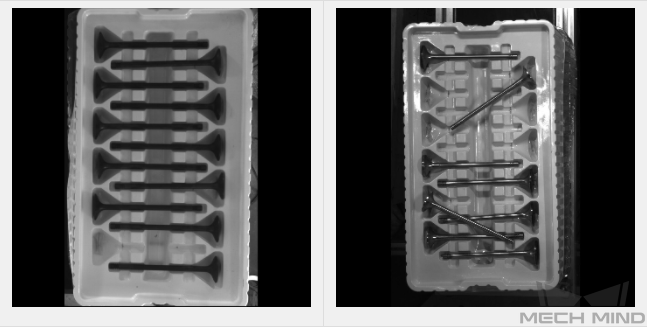

An engine valve assembly project: Single object class. Determining whether the object is correctly placed in the slot is needed. Since outside the slot, the object may appear in various positions and orientations, it is necessary to consider different positions and orientations, and 20 images were acquired for objects outside the slot. In the slot, only the factor of different positions needs to be considered, so 10 images were acquired for objects inside the slot.

-

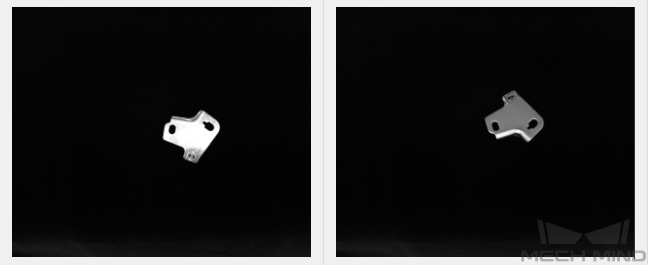

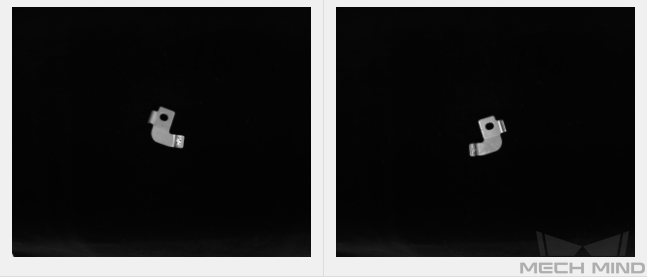

A sheet metal project: Two object classes. Different object sizes need to be recognized. Objects may come in different positions and orientations. Twenty images were acquired for the front and back sides each.

Object Detection

-

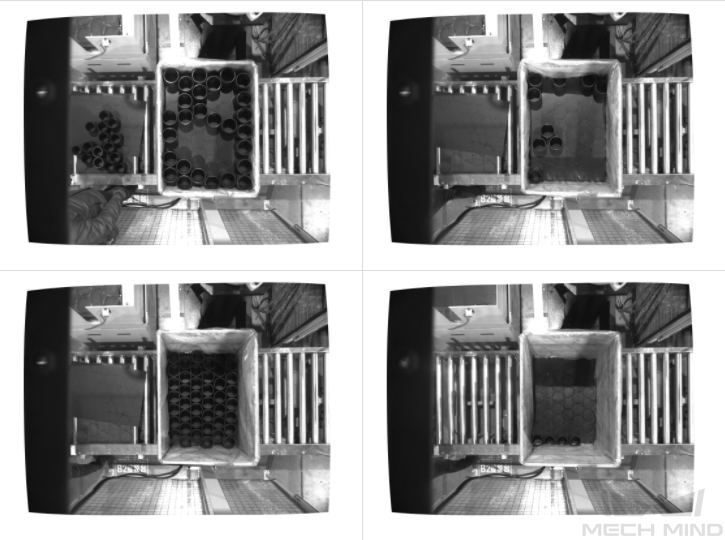

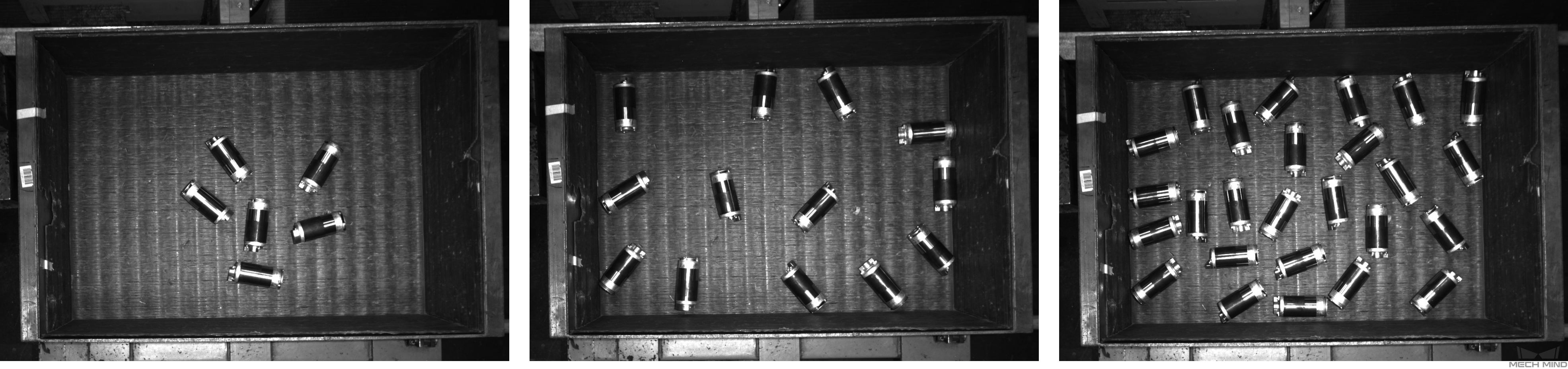

An object inspection project: The incoming objects are rotors scattered randomly. The project requires accurate detection of all rotor positions. Thirty images were acquired.

-

Positions: In the actual application, the rotors may be in any position in the bin, and the quantity will decrease after picking each time.

-

Positional relationships: The rotor may come scattered, neatly placed, or overlapped.

-

-

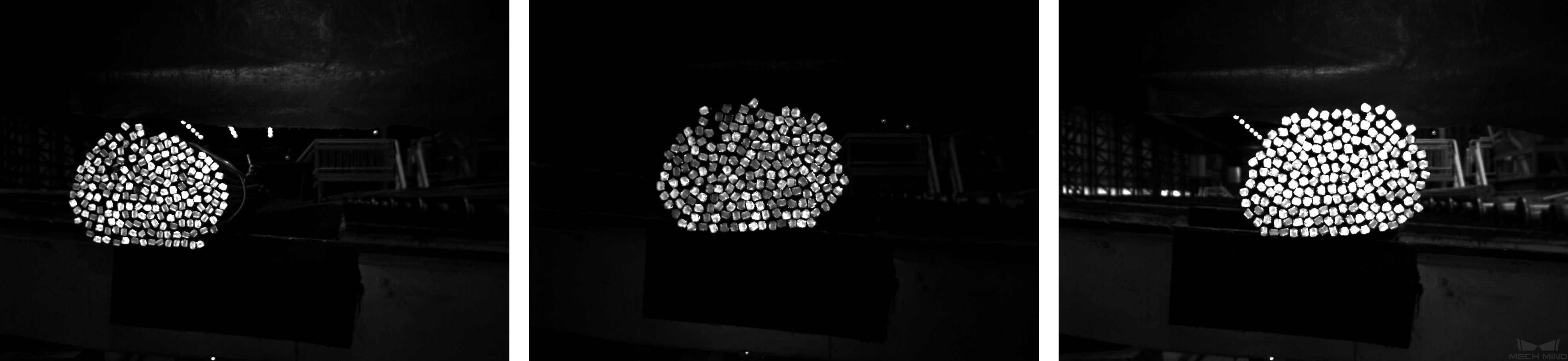

A steel bar counting project: The incoming objects are steel bars in bundles. The project requires accurate counting of steel bars. Twenty images were acquired.

-

Steel bars have relatively simple features, so only the variations of object positions need to be considered. Images in which steel bars are in any position in the camera’s field of view were acquired.

-