Basics

This section introduces the basic information about the Long Sheet Metal Parts solution, including its applicability, advantages, technical specifications, etc.

Applicability

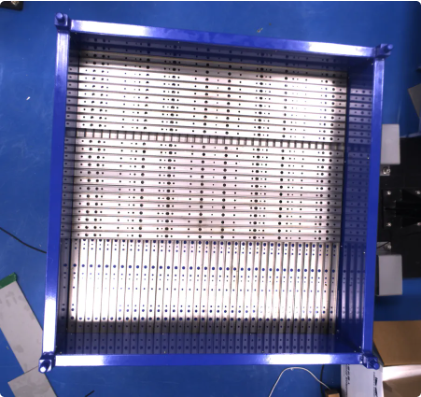

The table below introduces the applicability of this solution in terms of object types, object materials, placement, carriers, etc.

| Feasible | Illustration | |

|---|---|---|

Object type |

Long sheet metal parts |

|

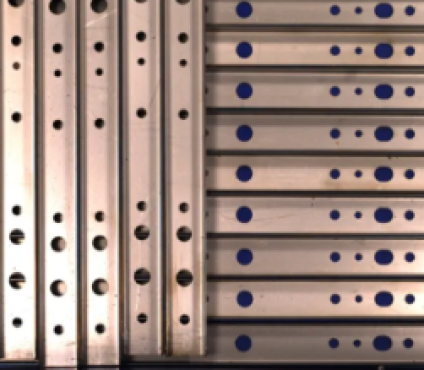

Object material |

Highly reflective |

|

Placement |

Neatly arranged. The target objects can rotate in a plane but cannot be placed on its side or upside down. |

|

Object carrier |

Bin |

|

Solution Advantages

The advantages of this solution are as follows:

-

Use the independently developed 3D positioning algorithm, and use edge matching to locate target objects, thereby greatly improving the accuracy of vision positioning.

-

Use the latest camera imaging algorithms to ensure stable imaging of highly reflective long sheet metal parts.

-

With a long baseline, the new camera model LSR XL provides a higher point Z-value repeatability.

-

By exploring typical cases in the software with the guidance of this document, beginner engineers can quickly deploy a vision solution.

Technical Specifications

The following table describes the technical specifications of the solution.

| Positioning accuracy | Recognition success rate | Execution time of vision system | Bin clearance rate | Tuning duration |

|---|---|---|---|---|

±2 mm |

More than 99% |

Less than 5 s |

More than 99% |

8 h × 2 (single type target object)

|

Project Difficulties

The difficulties of this solution are as follows:

-

Stable imaging: The vision system is expected to generate quality point clouds despite the high reflectivity of the target objects, which poses great challenges to imaging algorithms.

-

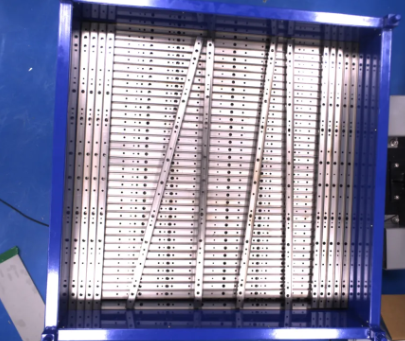

Positioning accuracy: Target objects of this type are thin and narrow. To avoid damaging them, it is necessary to ensure high accuracy in positioning and picking.

-

Object segmentation: The target objects are closely placed together. Without obvious gaps between adjacent target objects, it is difficult to segment them.