Solution Deployment FAQs

This section introduces the common problems, possible causes, and solutions for the Small Sheet Metal Parts solution.

Problem 1: Long Path Planning Time

Possible Causes

-

The pose sequence output by Mech-Vision is unreasonable, leading to an increased number of path-planning failures in Mech-Viz.

-

There is a problem with the Mech-Viz project parameter configuration.

-

Multiple unnecessary attempts based on the rotational symmetry were made when using Mech-Viz for path planning.

Solution

-

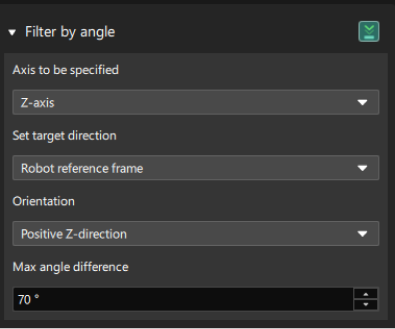

Use the pose adjustment tool to filter poses, such as using the Filter by angle method to filter out poses with inappropriate picking angles.

-

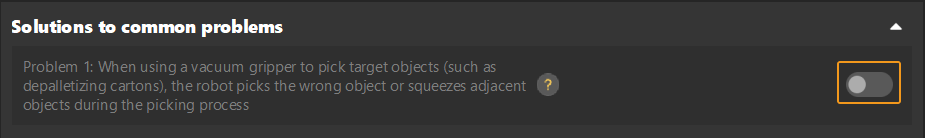

Disable time-consuming and unnecessary features in Mech-Viz, such as turning off the switch next toProblem One under Solutions to common problems in the Collisions functional panel, i.e., do not remove the point cloud of the target object.

-

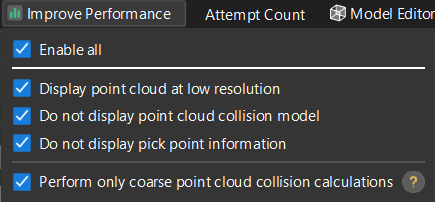

Make sure that all options under Improve Performance in the Mech-Viz toolbar are selected.

-

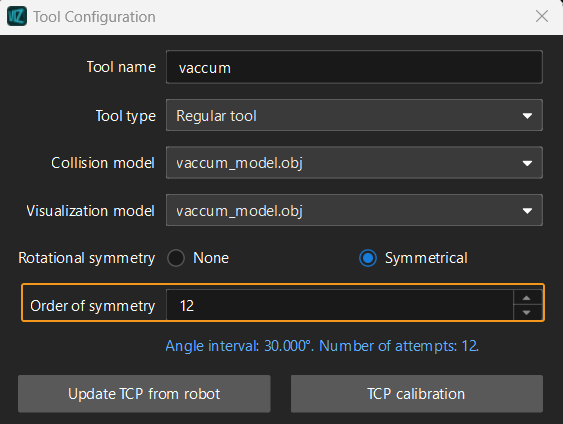

When configuring end tools, set the Order of symmetry value according to the actual situation, reducing unnecessary picking attempts.

Problem 2: Path Planning Failure

Possible Causes

-

The target object poses output by Mech-Vision are beyond the robot workspace.

-

The waypoint settings in Mech-Viz are unreasonable, resulting in collisions between the robot and scene objects.

-

When picking a target object with a tool, the tool collides with the point cloud representing the target object surface and the collision volume exceeds the Collision detection threshold.

Solution

-

Check if the target object poses output by Mech-Vision are correct.

-

Add appropriate intermediate waypoints in Mech-Viz according to the actual situation.

-

Consider whether collisions are allowed when the tool picks the target object.

-

If collisions are allowed, turn on the switch on the right of Problem 2 under Solutions to common problems in the Collisions functional panel and set the Non-detection range. Once this option is enabled, point cloud collisions in the adjacent area to the pick point will not be detected.

-

If collisions are not allowed, check if the Collision detection threshold is too small. If this parameter value is appropriate, but the target object does collide with the tool, other picking strategies may be considered.

-

Problem 3: Point Cloud Model Matching Failure or Missed Recognition of Target Object

Symptom

During point cloud model matching, there are instances of matching failures or missed target objects.

Possible Causes

-

The maximum number of poses obtained by matching has been reached.

-

The score of the matched pose is below the Confidence threshold.

-

Some target objects are overlapped by others and the Overlap ratio threshold is exceeded, leading to missed recognition.

-

Missing points in the target object point cloud results in missed recognition.

Solution

-

Increase the value of the Max outputs parameter.

-

Adjust the value of the Confidence threshold parameter according to the actual situation to remove the lower score poses.

-

In actual applications, a larger Coincidence ratio threshold and Overlap ratio threshold can be used if picking of the overlapped and coinciding target objects is allowed.

-

Adjust camera exposure parameters in Mech-Eye Viewer, and set the Fringe Coding Mode to Reflective to obtain a complete point cloud of the target object. For detailed descriptions of the camera parameters, please refer to Camera Parameter Reference.

Problem 4: Low Bin Clearance Rate

Possible Causes

-

The tool collided with the bin when picking target objects in the corners of the bin, and the target object failed to be picked.

-

Target objects are entwined or overlapped, resulting in matching failure.

-

When only the target objects with narrow surfaces facing up are left in the bin, the vacuum gripper with a single suction cup cannot pick these target objects.

Solution

When it is detected that there are target objects in the bin that cannot be picked, you can use other devices to shake the bin. For example, use a conveyor belt with a ridged roller to move the bin, allowing the ridged roller to shake the bin as the conveyor belt moves. If you find that the target objects in the bin cannot be picked, you can change the positions of the target objects by shaking the bin, and then try to pick them again.

The effect of shaking the bin in actual projects is shown below.