Basics

This section introduces the basic information about the Small Metal Parts in Deep Bin solution, including its applicability, advantages, technical specifications, etc.

Applicability

The table below introduces the applicability of this solution in terms of object types, object materials, placement, carriers, etc.

| Feasible | Illustration | |

|---|---|---|

Object type |

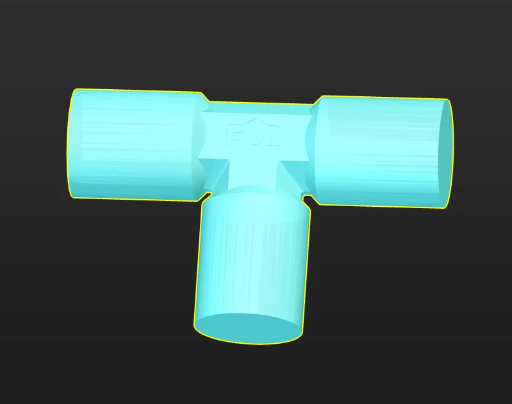

Small metal parts of different types, such as straight, elbow, three-way, and four-way |

|

Object material |

Non-reflective or slightly reflective |

|

Placement |

Randomly arranged |

|

Object carrier |

Deep bin |

|

Solution Advantages

The advantages of this solution are as follows:

-

Suitable for picking small metal parts in various types, small batches, and mixed-case production environments.

-

The intelligent planning of the picking sequence and picking method enables a stable picking of randomly stacked small metal parts.

-

The overall productivity can be improved with 3D vision-guided robot picking.

-

By exploring typical cases in the software with the guidance of this document, beginner engineers can quickly deploy a vision solution.

Technical Specifications

The following table describes the technical specifications of the solution.

| Positioning accuracy | Recognition success rate | Execution time of vision system | Bin clearance rate | Tuning duration |

|---|---|---|---|---|

±2 mm |

More than 99% |

Less than 3 s |

More than 97% |

8 h × 2 (single type target object)

|

Project Difficulties

The difficulties of this solution are as follows:

-

Positioning accuracy: The metal parts are small and randomly stacked in a deep bin. The vision system is required to generate high-quality point clouds and calculate the poses of small metal parts for high-accuracy positioning.

-

Picking strategy: For small metal parts that are randomly stacked and have different orientations, considering factors such as the pose of the metal parts, robot path constraints, and collision avoidance, the appropriate pick points and picking strategy should be selected to ensure the bin clearance rate.

-

Flexible and easy to use: Suitable for picking target objects of different specifications. The vision solution needs to be easy to deploy while meeting user requirements for efficiency, cost control, and other factors.