Risk Assessment and Fixes

During the deployment of the solution, there will be several risks, and this section will evaluate the possible risks and provide corresponding fixes.

Material Spillage over the Turnover Box Edge

-

Risk: Material inside the turnover box overflows above the top edge, obscuring the edge features of the turnover box.

-

Solution: Enforce strict control over incoming materials to ensure none exceed the turnover box boundaries.

Partition Flush with Turnover Box Edge

-

Risk: There are partitions in the turnover box. The partitions are flush with the top edge of the turnover box.

-

Solution: Use deep learning to segment the turnover box edge features, or use 2D image thresholding to segment the edges before matching.

Complex Ambient Lighting Conditions

-

Risk: Complex and varying ambient lighting can cause turnover box surfaces to be overexposed or underexposed, leading to visual recognition anomalies.

-

Sunlight or ambient light interference in the factory may cause the turnover box surfaces to be overexposed.

-

Shadows from walls or columns may cause the turnover box surfaces to be underexposed.

-

Significant differences between daytime and nighttime lighting may result in overexposed or underexposed turnover box surfaces.

-

Solution: Provide supplemental light and shading according to the actual situation of the workstation. Please refer to Shading Solutions for details.

Low Positioning Accuracy of the Camera Mounting Frame Slide Rail

-

Risk: When a sliding device is used for the camera bracket, the low positioning accuracy of the sliding rail can result in inaccurate robot picking.

-

Solution: It is recommended to use a steel-frame camera mounting structure. When a sliding device is required, use a servo motor with a rail positioning accuracy of less than 0.1 mm.

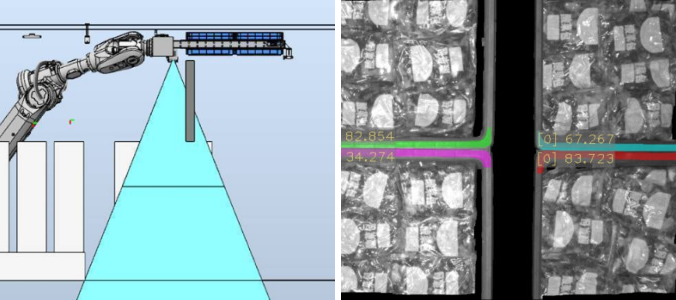

Inappropriate Camera Mounting Height

-

Risk: When using the Eye-in-Hand mounting method, the camera is fixed on the robot arm. The robot arm’s reachability and the on-site height limitations may prevent the camera’s field of view from covering the entire turnover box stack.

-

Solution: When mounting the camera in Eye-in-Hand mode, verify the robot’s reachability and ensure the camera’s field of view fully covers the entire turnover box stack as much as possible.

Improper Turnover Box Pallet Pattern

-

Risk: When the turnover box stack extends beyond the camera’s field of view or working distance, it may result in incomplete image capture or poor-quality point clouds.

-

Solution: Mount the camera according to its working distance, or add a lifting device to adjust the camera’s height.

Communication between One IPC and Multiple Robots

-

Risk: Using one IPC to communicate with multiple robots simultaneously leads to communication challenges.

-

Solution: Equip each robot with a separate IPC to ensure that one IPC communicates with only one robot.

High Requirement on Vision Cycle Time

-

Risk: When the requirement of vision cycle time is high, the vision system may not provide the vision result within the specified time frame.

-

Solution: The time from receiving commands to responding with vision information is typically less than 4 seconds. If you need to speed up the cycle time, you can mount the camera in Eye to Hand mode to incorporate the visual recognition time into the robot’s motion cycle.

Inconsistent Turnover Boxes

-

Risk: Turnover boxes used for a long time may become deformed or warped, affecting the stability of visual recognition.

-

Solution: Conduct picking stability tests on such turnover boxes in the early stages to ensure reliable picking.

Improper Robot Selection

-

Risk: The slot gap between the upper and lower turnover boxes is small. Using a four-axis robot may lead to unstable palletizing.

-

Solution: It is recommended to use a six-axis robot for turnover box palletizing.

Improper Gripper Design

-

Risk: When turnover boxes are tightly stacked, the gripper cannot simultaneously grasp all four edges of a box.

-

Solution: It is recommended to use adjacent-edge clamping or single-sided fixation grippers, and to validate the gripper’s load-bearing capacity.