Bag Opening Device Design

This section introduces the design of bag breaking devices in single-case sack depalletizing. Common bag opening devices include rotary and linear types. The design considerations and structure of both types are described below.

Rotary Bag Opening Device

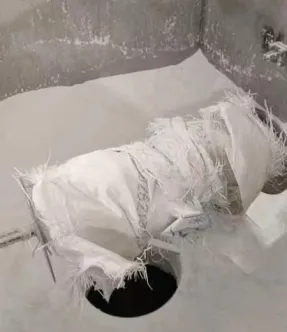

A common rotary bag opening device is shown below. It creates a relatively large cut during bag opening, which facilitates material discharge.

Design considerations for rotary bag opening devices:

-

The cutting teeth of rotary devices are sharp and can easily shred sacks, causing debris to mix with the material. Therefore, in industries such as food and pharmaceuticals, where there are requirements on debris content in the material after bag opening, rotary devices are generally not recommended.

-

The design should prevent packaging material from winding around the blades (as shown below), as this may interfere with subsequent bag-opening operations.

Linear Bag Opening Device

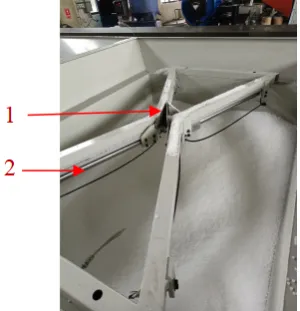

A common linear bag opening device is equipped with a cross-shaped blade, as shown below. During operation, the robot picks up the sack and presses it downward onto the blade to open the bag.

Design considerations for linear bag opening devices:

-

If material inside the sack is heavily clumped, or the cut size is insufficient for smooth discharge, it is recommended to add a cylinder or motor below the blade to extend the cut length. The cylinder structure is shown below, where 1 is the blade and 2 is a rodless cylinder.

-

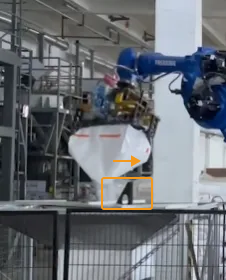

For sacks with good material flow, a single blade can be used as shown below. During operation, the robot picks up the sack and moves in the direction shown below to cut it open.

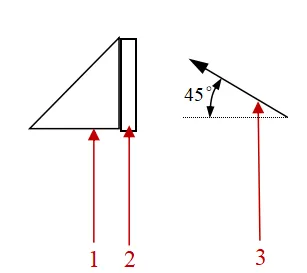

The structure of the single blade is shown below, where 1 is the blade, 2 is the cutting edge, and 3 indicates the sack movement direction.

-

A blowing device can be added to the bag opening device as needed. After material discharge, blowing helps further reduce leftover material.