Dust Explosion-Proof Design

This section introduces the dust explosion-proof design in single-case sack depalletizing.

At the depalletizing site, a certain level of dust is present. When the dust concentration reaches a critical level (lower limit: 20-60 mg/m³, upper limit: 2–6 kg/m³) and encounters a heat source or open flame, a rapid chemical reaction may occur, releasing a large amount of heat and leading to a dust explosion.

Dust explosions are highly destructive. Therefore, in high-concentration dust environments, it is generally necessary to add a protective cover for the camera.

The design requirements for the camera protective cover are as follows.

-

Shell: Welded using Q235 steel plates with a thickness of 10 mm–20 mm.

-

Bottom Material: To meet the imaging requirements of the camera, the bottom of the protective cover should be made of transparent material, generally 8 mm thick tempered glass is recommended.

-

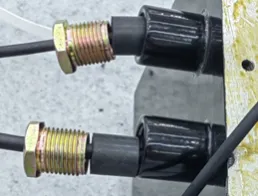

Cable Entry Holes: Special treatment should be applied to the cable entry and exit of the protective cover, as shown in the figure below.