Gripper Design

This section introduces the gripper design in single-case sack depalletizing solution, including gripper selection and gripper-related component design.

Common Gripper Model Selection

Vacuum Gripper

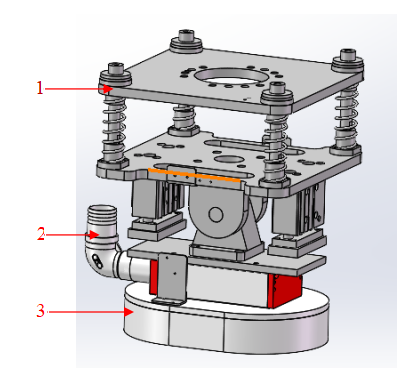

Vacuum grippers are often used to pick sacks with sturdy outer packaging, good airtightness, and relatively smooth surfaces with few wrinkles. For underfilled or half-filled sacks, this type of gripper performs poorly. The structure of a vacuum gripper is shown below, where 1 is the mounting plate, 2 is the vacuum hose port, and 3 is the suction cup.

When selecting a vacuum gripper, attention should be paid to the choice of each component, as detailed below.

-

Suction Cups: When choosing suction cups, consider the sack material and its properties. Large-chamber foam or rubber suction cups are generally preferred. The foam thickness should accommodate possible tilting or wrinkles on the sack, and the suction cup chamber should not be too large, just sufficient to meet the picking requirements.

-

Vacuum System: When selecting the vacuum system, consider the airtightness of the sack’s outer packaging and the sack weight. Generally, a high-flow fan and steel wire hose as the vacuum pipe are recommended.

-

Vacuum Breaker: A positive-pressure air circuit is installed inside the suction cup to ensure empty sacks can be smoothly released and placed after opening.

Insert Gripper

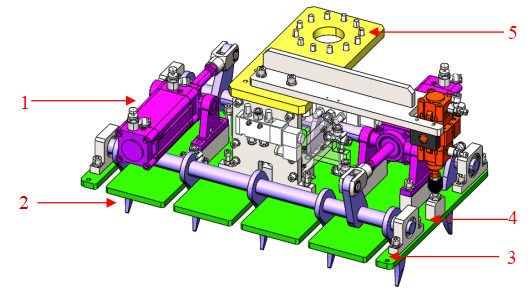

Insert grippers are often used for picking sacks with strong, tear-resistant outer packaging. Depending on the motion direction of the inserting teeth, insert grippers can be classified as internal insert grippers and external insert grippers.

-

Internal Insert Gripper: As shown below, the internal insert gripper consists of 1—swing cylinder, 2—left inserting tooth, 3—swing cylinder mounting plate, 4—right inserting tooth, and 5—flange mounting plate.

-

External Insert Gripper: As shown below, the external insert gripper should be designed with attention to the overall dimensions and motion path of the external inserting teeth to avoid collisions with surrounding sacks during picking.

Design of Gripper-Related Components

Material Shaking Device

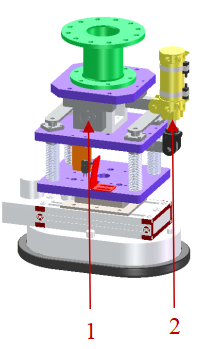

In general, clients expect as little residual material as possible inside the sack after opening it. Therefore, a material shaking device is designed on the gripper to effectively reduce the amount of residual material remaining in the sack.

The principle of the material shaking device is relatively simple: it achieves the shaking function through high-frequency reciprocating motion. For example, repeatedly and rapidly extending and retracting the cylinder shaft can effectively shake out the material inside the sack. The structure of the material shaking device is shown below, where 1 is the rotating shaft and 2 is the shaking cylinder.

The working effect of the material shaking device is shown below.

Pallet Picking Device

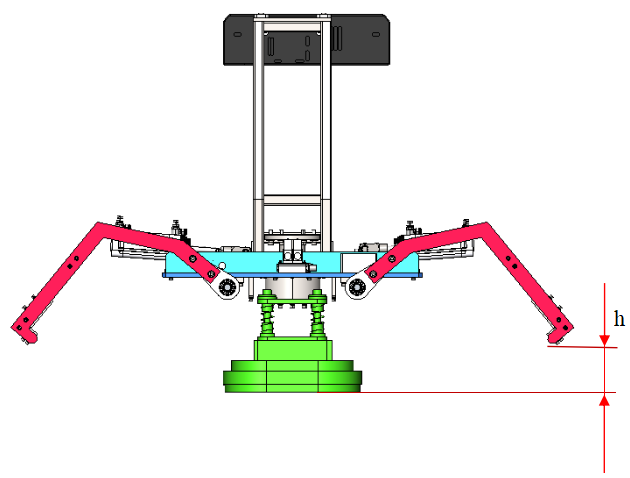

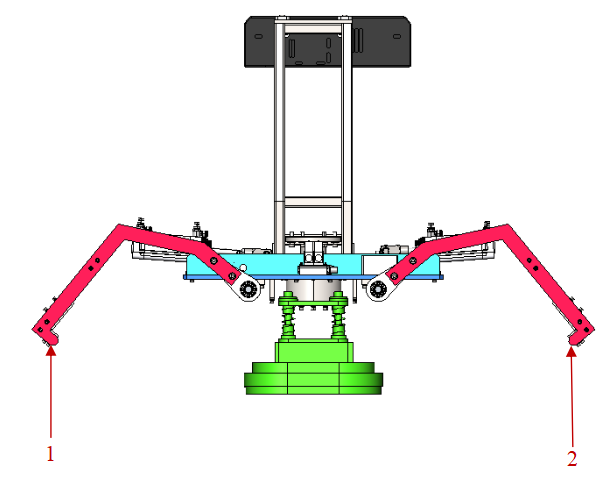

In depalletizing scenarios, it is usually necessary to remove the entire stack of sacks at once. Therefore, the empty pallet after depalletizing needs to be picked up and transferred to a designated location. The pallet picking device is shown below, where 1 is the left arm and 2 is the right arm.

In scenarios where incoming sacks are irregularly arranged, to avoid collisions between the pallet picking device and surrounding sacks during picking, sufficient clearance should be maintained. In the figure, this clearance is represented by h, and the specific dimension should be determined based on the height differences among sacks on the same layer.