Manual Re-Calibration in the Eye-in-Hand Setup (Six-Axis Robots - Using Multiple Random Calibration Board Poses Method)

This how-to guide introduces how to complete the manual re-calibration for six-axis robots using the multiple random calibration board poses method in the eye-in-hand (EIH) setup.

Preparation before Calibration

Before hand-eye calibration, you need to finish the following preparations:

Construct the Vision System

Construct the Mech-Mind Vision System by referring to the section Vision System Hardware Setup.

You need to use Mech-Eye Viewer, Mech-Vision and Mech-Viz during hand-eye calibration. Please ensure that they have been installed and are running the latest versions.

Prepare the Materials Required for Calibration

The manual calibration in the EIH setup needs to use the calibration board.

Please prepare the calibration board according to the following requirements:

-

Ensure that the circles of the calibration board are clearly visible and without obvious scratches, and the board does not suffer from deformations.

-

In the EIH setup, please place the calibration board in the center of the working plane, where target objects are to be placed.

In addition, before calibration, move the robot to the starting point for calibration.

Check the Point Cloud Quality of the Calibration Board

| The point cloud quality of the calibration board will affect the accuracy of hand-eye calibration. Check the point cloud quality of the calibration board to ensure the accuracy and reliability of the calibration results. The calibration process includes the step of checking the point cloud quality of the calibration board. You can also check the point cloud quality of the calibration board before starting the calibration to save time. |

-

Place the calibration board horizontally at the center of the working plane within the camera’s field of view.

-

Open the Mech-Eye Viewer software, select the camera used by the project, and then select the “calib” parameter group and adjust camera parameters.

-

Adjust the 2D parameters to ensure that the overall 2D image is not too dark, and each calibration circle is clearly visible.

-

Adjust the 3D parameters to ensure that each calibration circle on the calibration board is complete and visible.

If the on-site ambient lights are not ideal and affect the quality of 2D images and point clouds, you can use shading or supplemental light to improve the lighting conditions.

-

Make sure that the point cloud quality of the calibration board is up to standard after completing the preceding steps.

Normal Overexposed Underexposed 2D image

Point cloud

Complete Pre-calibration Checks

Please refer to Pre-calibration Checks and complete the following checks:

-

Confirm that the robot base is mounted securely.

-

Confirm that the camera mounting frame and camera are mounted securely.

-

Confirm that the absolute accuracy of the robot meets the requirements for use.

-

Verify robot model parameters.

-

Confirm that the camera is warmed up.

Pre-calibration Configuration

-

Open Mech-Vision, select a project in the project list, and then click the Camera Calibration button in the toolbar. The Configuration before Calibration window will be prompted.

-

After confirming that pre-calibration checks are completed, click I’ve finished all checks, and then click Next.

-

In the Select how to calibrate window, select the Load calibration parameters radio button, select the parameters that were calibrated for the project, and then click the Next button.

-

In the Select parameter usage window, select Continue working on the calibrated camera radio button, and then click the Next button.

Camera status should be displayed as connected. -

In the Select calibration task window, select Recalibrate from the start radio button, and then click the Calibration button. The Calibration (Eye in Hand) window will be prompted.

Till now, you have completed the pre-calibration configuration and can start the calibration procedure.

Perform Calibration

Connect to Camera

By default, the camera used in the project is set to be connected. Please click the Next button to continue the calibration procedure.

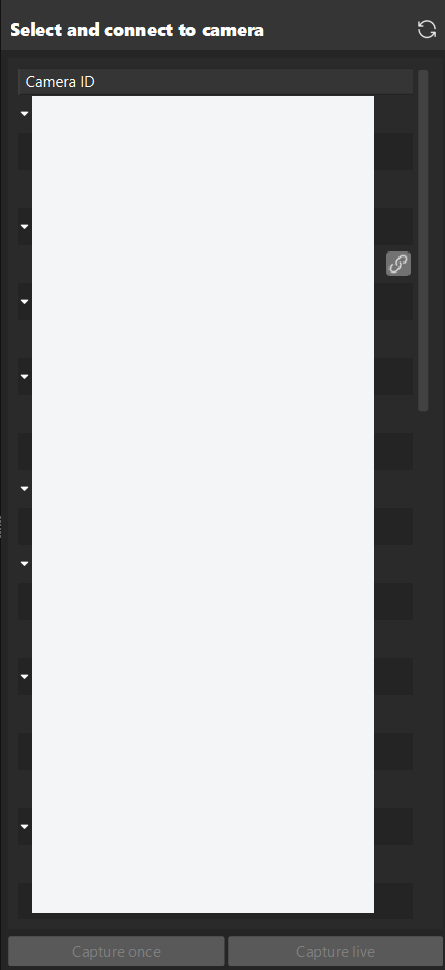

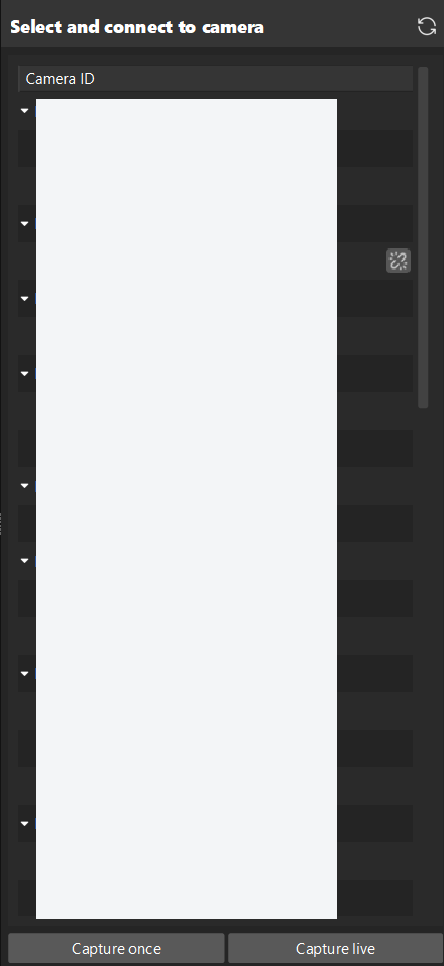

If the camera is not connected, please complete the camera connection by referring to the following instructions:

-

In the Connect to camera step, select the camera to connect in the Camera ID list, and then click the

button or double-click the camera entry to connect to it.

button or double-click the camera entry to connect to it.

-

After the camera is connected, click the Capture live or Capture once button.

-

In the Image viewer panel, ensure that the camera can capture images normally and click the Next button on the bottom bar.

Mount Calibration Board & Check Intrinsic Parameters

-

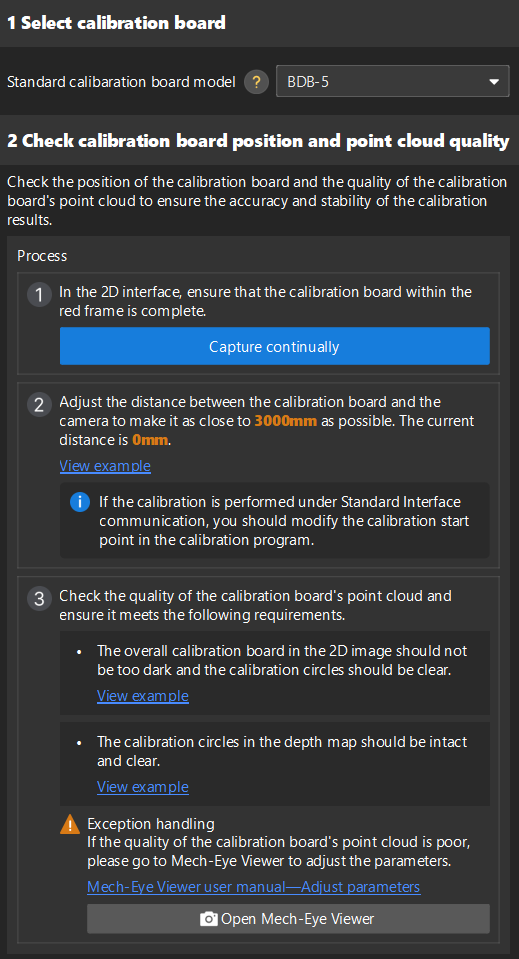

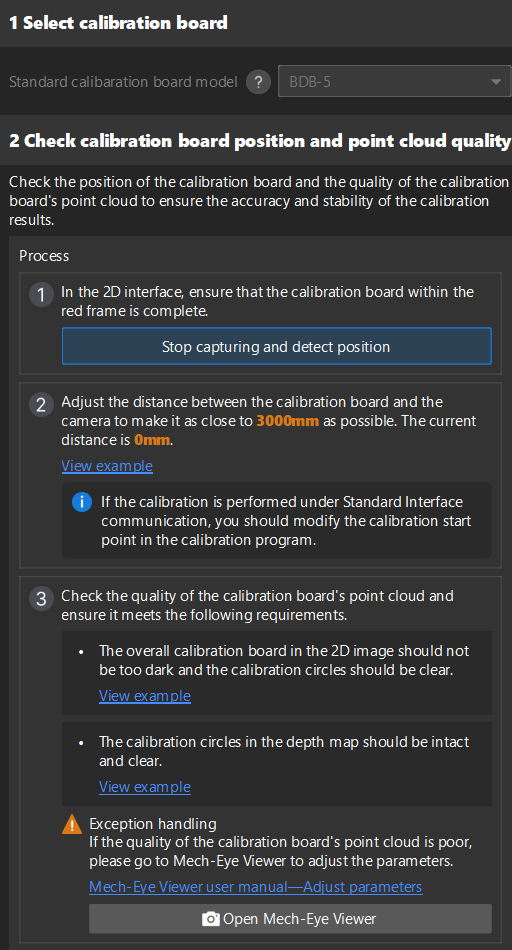

In the Mount calibration board & check intrinsic parameters step, set the Standard calibration board model parameter in the 1 Select calibration board area.

-

In the 2 Check calibration board position and point cloud quality area, read carefully the requirements on the calibration board position and point cloud quality, and then click the Capture continually button. The Capture live button will turn into Stop capturing and detect position.

-

Manually move the robot to an appropriate position, ensuring the calibration board is fully within the red frame, and the distance between the calibration board and the camera is as close to the recommended value on the interface as possible.

If the Standard Interface communication mode is used for calibration, after adjusting the distance between the calibration board and the camera according to the prompts on the interface, the robot’s position can be used as the starting point for calibration. -

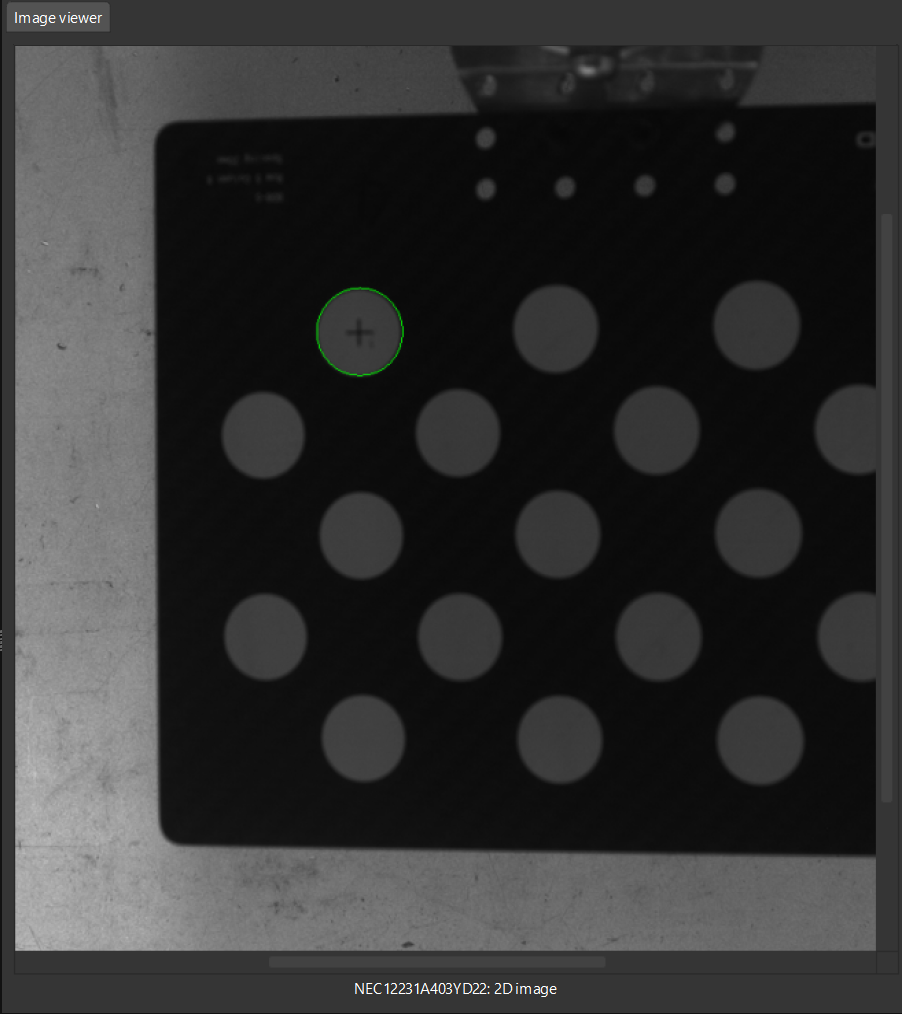

Please ensure that the 2D image and depth map of the calibration board meet the requirements, and then click the Stop capturing and detect position button.

If the captured images do not meet the requirements, click Open Mech-Eye Viewer button to open the Mech-Eye Viewer software, adjust the 2D and 3D exposure parameters and re-capture images. Please note that you need to change the Parameter group parameter to “calib” first.

-

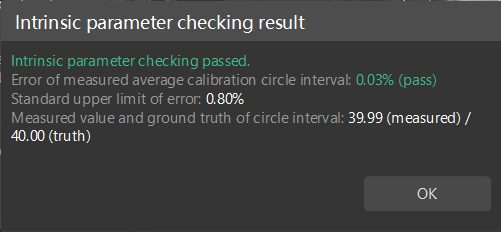

In the 3 Check intrinsic parameters area, click the Check intrinsic parameters button.

-

Confirm the results of the camera intrinsic parameter check.

-

If the camera intrinsic parameter check passes, click the OK button in the prompted window, and then click the Next button on the bottom bar.

-

If the intrinsic parameter check fails, you can draw aid circles to assist in the intrinsic parameter check, and then click the Recheck intrinsic parameters button.

-

Draw Aid Circle

-

To draw an aid circle, click the Draw an aid circle button.

-

In the right Image viewer panel, right-click the calibration board image, clear the Fit to window checkbox, press the Ctrl key and drag the roller to adjust the image to a suitable size.

-

Move the mouse pointer to the cross center point of the calibration circle, press the left mouse button and make the aid circle completely include the calibration circle and then release the left mouse button.

-

Click the Recheck intrinsic parameters button, and confirm that the camera intrinsic parameter check passes. If the intrinsic parameter check still fails, please contact Technical Support.

Obtain Images and Poses

-

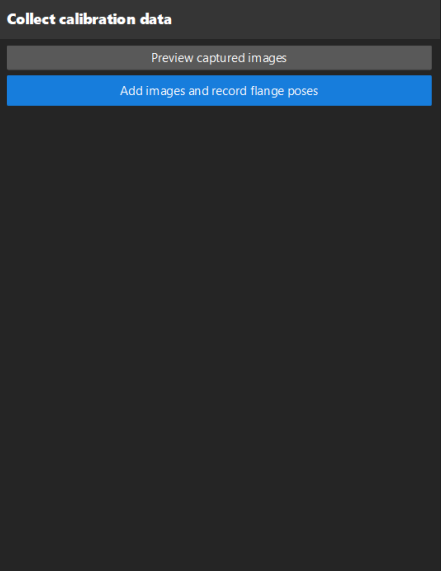

In the Obtain Images and Poses step, control the robot to move to different calibration points and then click the Add images and record flange poses button.

After moving the robot to different calibration points, please record the pose of each point in the robot program for easy retrieval during re-calibration. -

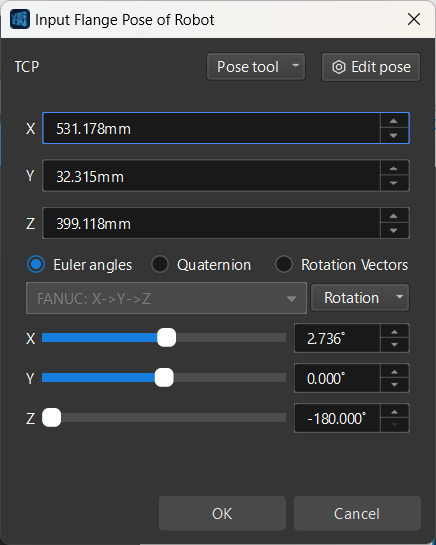

In the prompted window, enter the robot flange pose.

Please create a new local file (.txt or .xlsx) to save the input robot flange poses for easy input during re-calibration. -

Repeat the above steps until the added calibration points meet the data requirements. Then click the Next button on the bottom bar.

Verify Calibration Results

This section provides methods for quickly validating calibration results.

View Error Point Cloud in Point Cloud Viewer

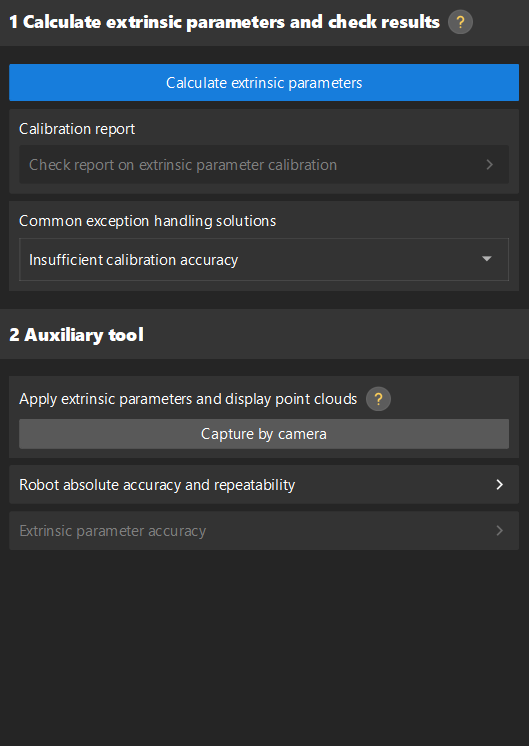

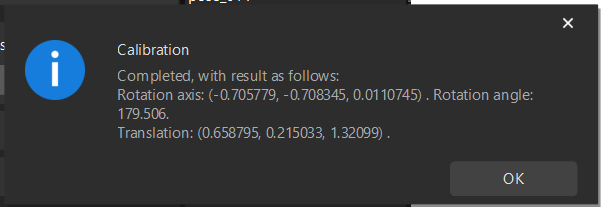

After calculating the camera extrinsic parameters, perform the following operations:

-

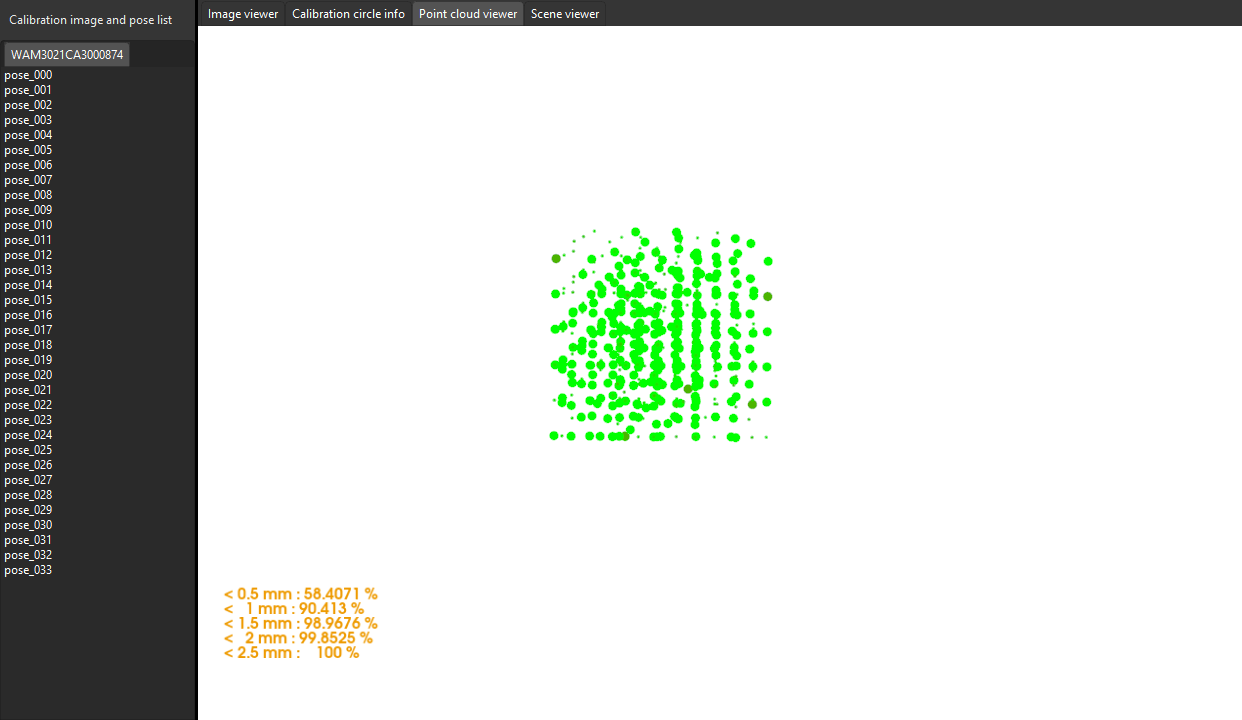

In the Calculate extrinsic parameters step, view the error point cloud in the right Point cloud viewer panel after the calibration calculation is complete.

The error point cloud shows the deviation between the calculated value and the actual value of the circles on the calibration board. For the detailed description, please refer to Error Point Cloud Description. -

Confirm that the calibration accuracy meets the project’s requirements. Find the error value with the 100% percentage to get the rough calibration accuracy.

For example, the point cloud view after calibration using multiple random calibration board poses is shown in the figure below. The calibration error is within ±2.5 mm.

Roughly Check Coincidence Degree between the Point Cloud of the Robot and the Robot Model in Scene Viewer

After calculating the camera extrinsic parameters, please perform the following operation:

-

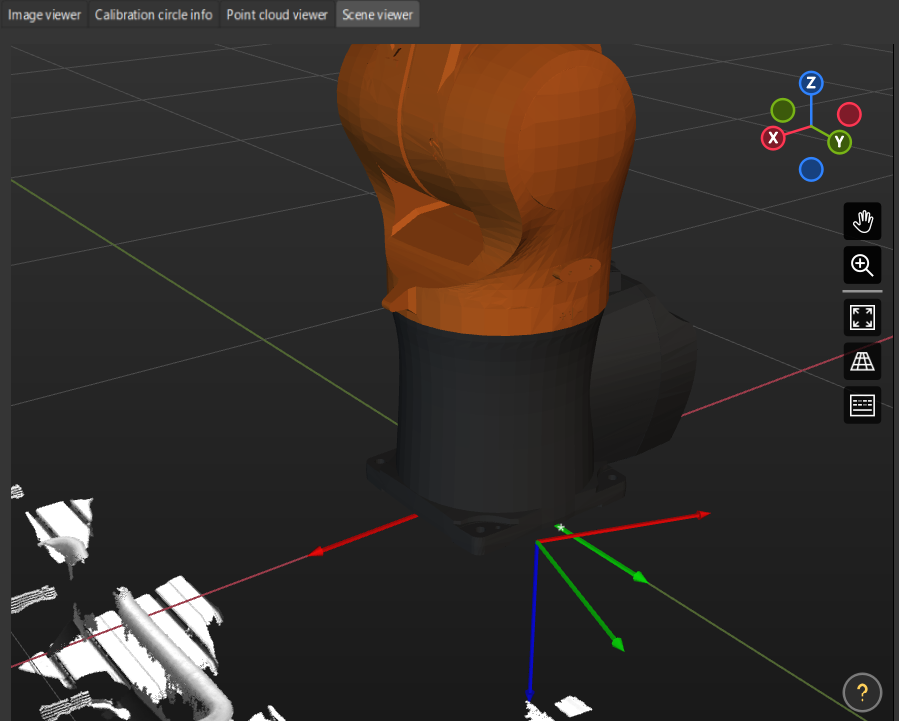

Move the robot end effector to a position where the camera can capture images of the base.

-

In the Calculate extrinsic parameters step, click the Capture by camera button in the 2 Auxiliary tool area. This operation triggers the camera to capture images.

-

In the right Scene viewer panel, visually check coincidence degree between the point cloud of the real robot and the robot model. If the point cloud of the robot roughly coincides with the robot model, the calibration is successful.

As shown in the figure, the color part is the robot model, the black part is the robot point cloud. From the figure, you can learn that the robot model and the robot point cloud roughly coincides. This indicates that the calibration result can be used.

| If the camera cannot capture the base due to robot degrees of freedom or workspace limitations, you can choose to view the offset of the calibration board’s point cloud relative to a fixed point in the scene viewer instead. |

Use the Extrinsic Parameter Accuracy Validation Tool to Validate Extrinsic Parameters

For high-precision scenarios (within ±2mm), this method should be used to thoroughly validate the extrinsic parameters.

In the Calculate extrinsic parameters step, click Extrinsic parameter accuracy to open the tool. Please refer to the tool’s guidance to validate the extrinsic parameter accuracy and generate the final evaluation report.

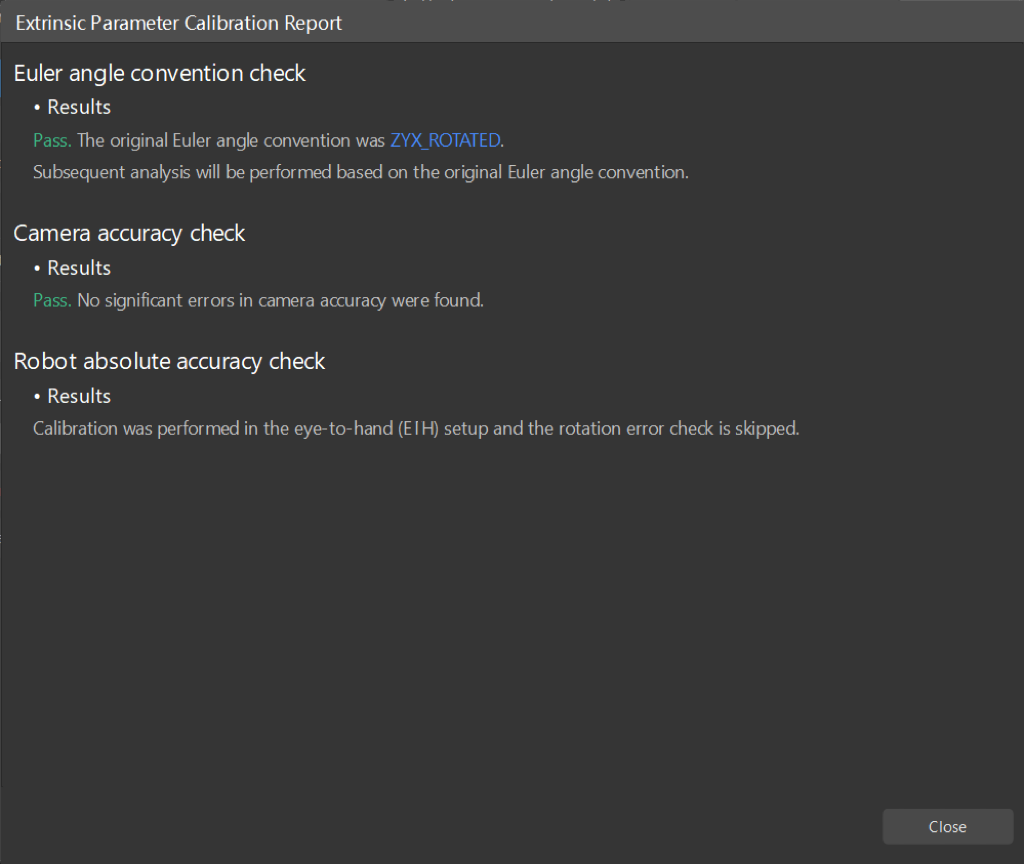

If the calibration accuracy does not meet the requirements, you can click the Check report on extrinsic parameter calibration button to view the results of Euler angle convention check, camera accuracy check, and robot absolute accuracy check.

|

If the camera accuracy in the report does not meet the requirements, please follow the recommendation to troubleshoot the camera accuracy errors. |

Apply Calibration Result

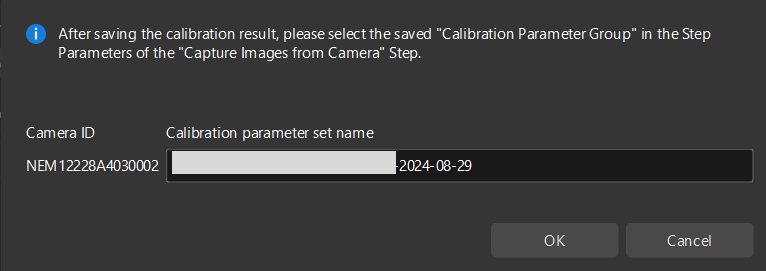

Navigate to the Calculate extrinsic parameter step, click Save at the bottom. Then configure the save settings in the Save Calibration Parameter Group dialogue box, and click OK. The calibration result will be automatically saved in the “calibration” directory of the project.

|

After “Current project - Save file only” is selected, when you want to apply a new calibration parameter group later, navigate to the Step Parameters panel of the “Capture Images from Camera” Step, click the |

Till now, the calibration process is completed.