样例程序7:MM_S7_Viz_SwitchTCP

程序解读

以下为MM_S7_Viz_SwitchTCP样例程序的代码及相关解释说明。

| 与MM_S2_Viz_Basic样例相比,本样例主要新增了根据末端工具编号切换工具的功能(加粗部分的代码)。因此,下文不再重复解释与MM_S2_Viz_Basic样例相同部分的代码(详情请参考MM_S2_Viz_Basic样例说明)。 |

1: !-------------------------------- ;

2: !FUNCTION: trigger Mech-Viz ;

3: !project and get planned path, ;

4: !switch TCP according to ;

5: !the tool NO.;

6: !Mech-Mind, 2023-12-25 ;

7: !-------------------------------- ;

8: ;

9: !set current uframe NO. to 0 ;

10: UFRAME_NUM=0 ;

11: !set current tool NO. to 1 ;

12: UTOOL_NUM=1 ;

13: !move to robot home position ;

14:J P[1] 100% FINE ;

15: !initialize communication ;

16: !parameters(initialization is ;

17: !required only once) ;

18: CALL MM_INIT_SKT('8','127.0.0.1',50000,5) ;

19: !move to image-capturing position ;

20:L P[2] 1000mm/sec FINE ;

21: !trigger Mech-Viz project ;

22: CALL MM_START_VIZ(2,10) ;

23: !get planned path, 1st argument ;

24: !(2) means getting pose in TCP ;

25: CALL MM_GET_VIZ(2,51,52,53) ;

26: !check whether planned path has ;

27: !been got from Mech-Viz ;

28: !successfully ;

29: IF R[53]<>2100,JMP LBL[99] ;

30: !save waypoints of the planned ;

31: !path to local variables one ;

32: !by one ;

33: CALL MM_GET_POS(1,60,70,80) ;

34: CALL MM_GET_POS(2,61,71,81) ;

35: CALL MM_GET_POS(3,62,72,82) ;

36: !switch TCP according to the ;

37: !received tool NO. ;

38: IF R[81]=1,JMP LBL[1] ;

39: IF R[81]=2,JMP LBL[2] ;

40: JMP LBL[999] ;

41: ;

42: LBL[1:use tool NO.1] ;

43: !set current tool NO. to 1 ;

44: UTOOL_NUM=1 ;

45: !reset tool signal ;

46: !DO[1]=OFF ;

47: !set a Flag ;

48: F[1]=(ON) ;

49: JMP LBL[3] ;

50: ;

51: LBL[2:use tool NO.2] ;

52: !set current tool NO. to 2 ;

53: UTOOL_NUM=2 ;

54: !reset tool signal ;

55: !DO[2]=OFF ;

56: !set a Flag ;

57: F[2]=(ON) ;

58: JMP LBL[3] ;

59: ;

60: LBL[3:pick path] ;

61: !follow the planned path to pick ;

62: !move to approach waypoint ;

63: !of picking ;

64:L PR[60] 1000mm/sec FINE ;

65: !move to picking waypoint ;

66:L PR[61] 300mm/sec FINE ;

67: !add object grasping logic here, ;

68: !IF (F[1]),DO[1]=(ON) ;

69: !IF (F[2]),DO[2]=(ON) ;

70: PAUSE ;

71: !move to departure waypoint ;

72: !of picking ;

73:L PR[62] 1000mm/sec FINE ;

74: !move to intermediate waypoint ;

75: !of placing ;

76:J P[3] 50% CNT100 ;

77: !move to approach waypoint ;

78: !of placing ;

79:L P[4] 1000mm/sec FINE Tool_Offset,PR[2] ;

80: !move to placing waypoint ;

81:L P[4] 300mm/sec FINE ;

82: !add object releasing logic here, ;

83: !IF (F[1]),DO[1]=(OFF) ;

84: !IF (F[2]),DO[2]=(OFF) ;

85: PAUSE ;

86: !move to departure waypoint ;

87: !of placing ;

88:L P[4] 1000mm/sec FINE Tool_Offset,PR[2] ;

89: !move back to robot home position ;

90:J P[1] 100% FINE ;

91: !reset the Flags ;

92: F[1]=(OFF) ;

93: F[2]=(OFF) ;

94: END ;

95: ;

96: LBL[99:vision error] ;

97: !add error handling logic here ;

98: !according to different ;

99: !error codes ;

100: !e.g.: status=2038 means no ;

101: !point cloud in ROI ;

102: PAUSE ;

103: ;

104: LBL[999:label error] ;

105: !add handling logic here if the ;

106: !label is invalid ;

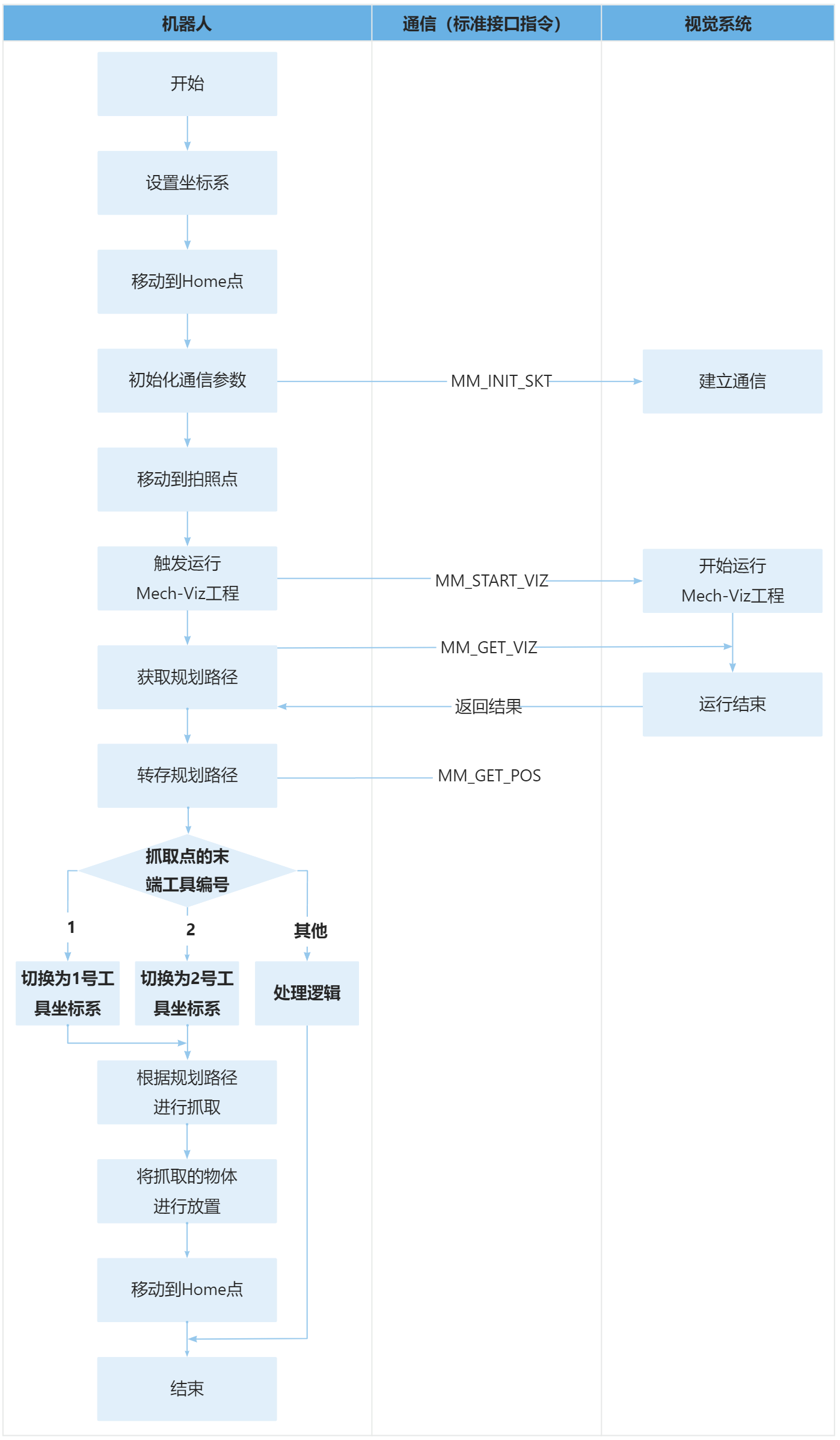

107: PAUSE ;上述样例程序代码对应的流程如下图所示。

下表为新增代码的逻辑解读。

| 流程 | 代码及说明 | ||

|---|---|---|---|

获取规划路径 |

因此,整条指令表示机器人获取Mech-Viz工程返回的规划路径。

|

||

转存规划路径 |

因此,“CALL MM_GET_POS(1,60,70,80)”整条指令表示将第一个路径点的工具位姿、标签和末端工具编号分别转存至指定寄存器。

|

||

根据末端工具编号切换末端工具 |

用户可根据R[81]寄存器值,决定机器人移动到抓取点时所使用的末端工具。上述代码的逻辑说明如下所示。

假设机器人通过DO[1]信号控制末端工具1,通过DO[2]信号控制末端工具2,则程序还需通过F[1]与F[2]两个标志分别建立两者关系。

接下来以末端工具编号1为例,讲解具体抓放流程。

机器人使用末端工具编号2的流程与上述流程类似,此处不再赘述。 |