Solution Deployment FAQs

This section introduces the common problems, possible causes, and solutions for the Highly Reflective Discs solution.

Problem 2: Poor Quality of Object Point Cloud

Symptom

The point cloud of the target object is of poor quality and does not meet the requirements, thus affecting subsequent picking.

Possible Causes

-

The camera exposure parameters were not set properly.

-

The ambient light on site was too strong, affecting the point cloud quality of the target object.

Solutions

-

Adjust camera exposure parameters in Mech-Eye Viewer, and set the Fringe Coding Mode to Reflective to obtain a complete point cloud of the target object. For detailed descriptions of the camera parameters, please refer to LSR L-GL Camera Parameters Reference.

-

Adjust the ambient light on site or use a shading device.

Problem 3: Deviation in Object Recognition Result

Symptom

The recognition result of the target object had a deviation and did not meet the requirements.

Possible Causes

-

The matching model was inappropriate.

-

The matching parameters were not set properly.

-

The recognition was not assisted by deep learning.

Solutions

-

If the point cloud of the target object fluctuates significantly, set Fine matching mode under the Matching mode category to Surface matching.

-

Set Performance mode under both the categories Coarse matching settings and Fine matching settings to High accuracy. Then, set Deviation correction capacity in Fine matching settings category to Small. Under the Adjust or filter poses from coarse matching category, set Select strategy to Adjust X-axis orientation, and set X-axis orientation to 0°. This ensures that the X-axis orientations of the matched poses of the target objects align as closely as possible with the X-axis orientations of the object center points, thus improving the picking accuracy.

-

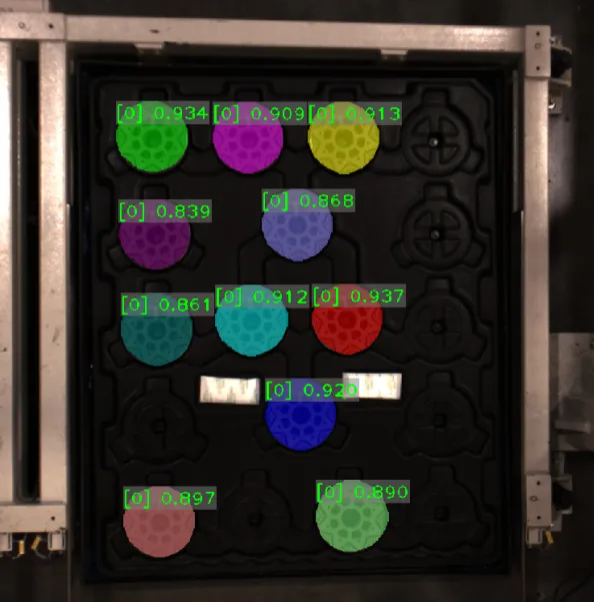

Use deep learning-assisted recognition to remove interference from trays and other scene point clouds, enhancing recognition performance.

Problem 4: Object Damage

Possible Causes

-

Target objects were accidentally damaged by squeezing and scraping with the pockets of the part tray during picking.

-

The target objects were not at the center of the pockets of the part tray, but were instead close to one side. Therefore, even a very small deviation in picking (e.g., 0.5 mm) might cause squeezing or scraping between the target objects and the pockets of the part tray, thus damaging the target objects.

Solutions

First, locate the center poses of the tray pockets and target objects respectively. Then, use the X and Y values of the tray pockets’ center poses to replace those of the target objects’ center poses. This ensures that the target objects are pushed towards the center of the pockets when the gripper closes during picking, preventing scraping between the target objects and the pockets and thus avoiding damage to the target object.