Gripper Design Workflow

This section introduces the general workflow for gripper design.

Before Design: Review Production Information

Before designing a gripper, relevant production information should be reviewed, such as basic information of target objects and incoming material conditions. Details are as follows.

-

Clarify basic target object information

-

Target object weight

-

Target object dimensions

-

Target object material

-

Target object manufacturing process

-

-

Confirm incoming material conditions of the target objects

-

Verify the type of carrier (pallet, shallow bin, deep bin, or rack), as well as the bin form (mesh, flat, or other) and dimensions.

-

Check if the incoming material affects picking.

-

Determine whether there are partitions between different layers of target objects and whether the partitions need to be picked.

-

Confirm whether manual intervention during picking is acceptable.

-

-

Clarify target object placement requirements

-

If target objects can be placed freely without regard to orientation or pose, the gripper design can be relatively simple.

-

If target objects must be placed at specific angles, orientations, or poses, additional flipping or rotation devices may be required.

-

If latter processes require high placement accuracy, the gripper design may be more complex, potentially requiring secondary positioning devices.

-

-

Define picking cycle time requirements

-

The picking cycle time should meet the requirements of upstream processes, downstream processes, or customer requirements.

-

The picking cycle time has a great impact on gripper design. In particular, when picking speed is high, stability must be ensured.

-

During Design: Define Key Design Considerations

In practical applications, grippers can be classified into finger-type grippers, magnetic grippers, and vacuum grippers. During design, each gripper type has specific key considerations, as described below.

Finger-Type Grippers

Finger-type grippers are recommended when the target object shape is unsuitable for vacuum picking and cannot be magnetized. They are suitable for complex-shaped target objects and enable stable picking. The figure below shows the picking of small rings with a two-finger gripper.

The key points of finger-type gripper design are as follows:

-

The gripper should be selected according to the target object weight. Ensure an adequate safety margin is maintained while meeting the required pick success rate and picking accuracy, with the gripper’s gripping force exceeding the minimum required to hold the target object by a sufficient amount to handle uncertainties and guarantee safe, reliable picking.

-

Design multiple picking methods, not limited to internal support or external clamping, to improve the success rate.

-

To avoid scratching the target object, ensure that the hardness of any gripper components in contact with the target object is lower than that of the object material.

-

Consider adding knurling on the fingers to increase friction.

-

Consider installing drop-detection sensors at appropriate positions on the gripper to add drop-detection capability and prevent problems caused by dropped target objects.

-

When a target object has multiple pick points, the finger design should accommodate all pick points. A minimum clearance of 2 mm should be maintained on one side to avoid collisions during picking.

|

It is recommended to design the pick points at the center of gravity of the target object in Mech-Vision to prevent flipping or dropping after picking. |

Magnetic Grippers

Magnetic grippers are suitable for metal target objects that are closely arranged, making it difficult to insert the gripper at the edges or sides, so that only the top surface can be contacted. Magnetic grippers adhere directly to the top surface the target object, ensuring stable and effective picking.

The key points of magnetic gripper design are as follows:

-

Select an appropriate electromagnetic gripper according to the weight of the target object to avoid excessive magnetic force that picks up multiple objects at once, or insufficient force that causes the target object to fall after being picked up.

-

Designing multiple picking positions can improve the chances of successful picking.

-

Consider installing drop-detection sensors at appropriate positions on the gripper to add drop-detection capability and prevent problems caused by dropped target objects.

-

For regular electromagnets, the magnetic force is recommended to be at least ten times the weight of the target object; for electro-permanent magnets, a safety factor of 3–5 should be selected based on the surface condition of the target object.

|

It is recommended to design the pick points at the center of gravity of the target object in Mech-Vision to prevent flipping or dropping after picking. |

Vacuum Grippers

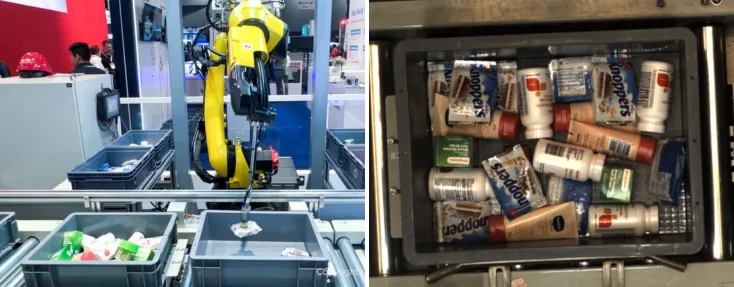

Vacuum grippers are recommended when incoming material contains mixed types of target objects, the surfaces are smooth and non-porous, the picking area can fully cover the object, and high picking accuracy is not required. The figure below shows the picking of products.

The key points of vacuum gripper design are as follows:

-

Select the vacuum element model based on the weight, picking position, and surface condition of the target object.

-

Design multiple vacuum attachment points to improve the success rate of picking.

-

Select appropriate suction cups according to the surface characteristics of the target object (e.g., smoothness, presence of air-leak holes) to ensure stable attachment.

-

Consider installing drop-detection sensors at appropriate positions on the gripper to add drop-detection capability and prevent problems caused by dropped target objects.

-

Pay special attention to potential flipping after picking when designing safety margins, and avoid excessive suction force that could damage the target object.

|

It is recommended to design the pick points at the center of gravity of the target object in Mech-Vision to prevent flipping or dropping after picking. |