Common Issues with Deep Bin Picking

This section introduces common issues and their solutions when using a gripper to pick target objects from a deep bin.

Inappropriate Gripper Structure Design

-

Symptom

The gripper’s outer contour dimensions are too large, resulting in an inappropriate structural design. When picking bottom-layer target objects in the bin, the gripper may collide with the bin or the objects, leading to a lower-than-expected clearance rate.

-

Solution

When designing the gripper, the following points should be considered.

-

Fully account for the depth of the bin to ensure successful picking of target objects under extreme conditions.

-

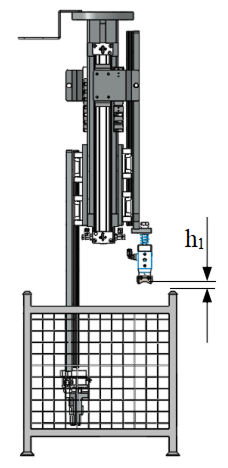

When picking bottom-layer target objects, ensure that the robot’s sixth-axis end, the camera, dresspack, and other accessories of the gripper maintain a safe distance from the top surface of the bin, as shown in the figure below at height h1.

-

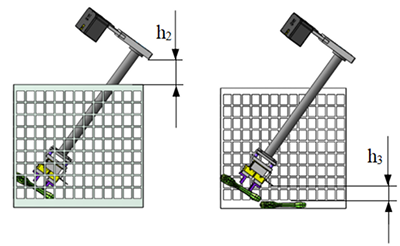

When the gripper picks target objects at a certain tilt angle, ensure that the robot’s sixth-axis end, the camera, dresspack, and other gripper accessories maintain a safe distance from the bin edges and other target objects, as shown in the figure below at heights h2 and h3.

-

In general, it is not recommended for the robot’s fifth and sixth axes to enter a deep bin for picking. However, if the target objects are relatively large and the bin has a special design (greater length and width but lower height), the above operation may be allowed at discretion.

-

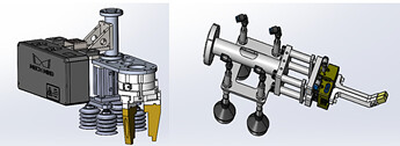

When multiple types of target objects need to be handled at the same workstation, multiple grippers should be designed to meet the above requirements. In general, grippers can be switched using a quick change device. Note that the precision of the quick change device must not affect the picking accuracy. In addition, do not mount the camera on the gripper side.

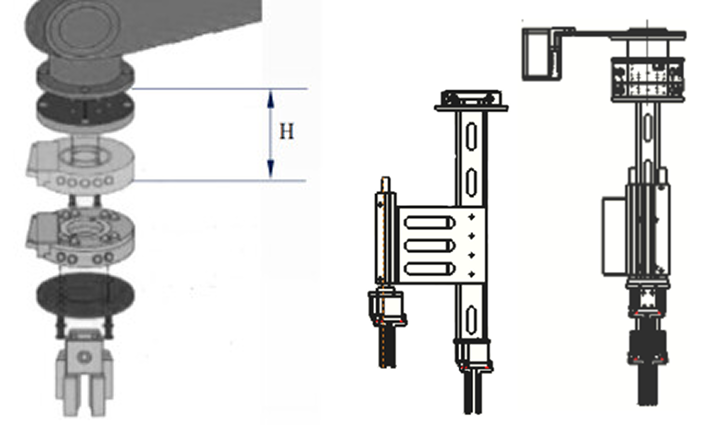

The mounting position of the quick change device is shown in the H area of the figure below.

-

When mounting multiple grippers and cameras, try to avoid arranging them in the same direction.

As shown in the figure below, when the target object is tilted, if the gripper is too long in a certain direction, it may collide with the bin during picking.

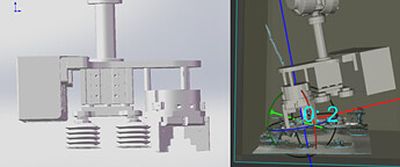

In actual production, gripper design can refer to the illustration below.

-

Poor Gripper Compatibility

-

Symptom

When the gripper has poor compatibility, accurate picking relies heavily on precise target object poses. However, due to the high randomness of deep-bin incoming material, combined with the characteristics of the target objects (e.g., reflectivity) and the overall accuracy of the production line, it is often difficult to consistently obtain precise target object poses. This may result in failed picking, dropped objects after picking, or even misplacement of the target objects.

-

Solution

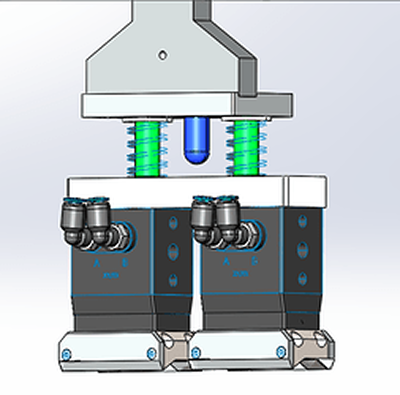

For scenarios with high picking accuracy requirements, consider adding a floating device to the gripper to better accommodate target object pose deviations and improve picking reliability, as shown in the figure below.

When designing the floating device, the following points should be considered.

-

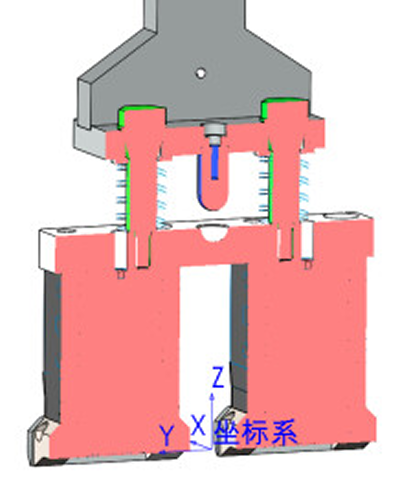

Ensure that the floating device can freely switch between the “floating” and “non-floating” states, and that the gripper immediately returns to its pre-pick state after picking a target object.

-

When the gripper is in the floating state, floating should only be allowed in the necessary direction(s); all other directions should remain fixed. For example, if the gripper floats in the Z direction, the X and Y directions must remain fixed.

A typical floating device design is shown in the figure below.

-

Improper Accessory Selection and Layout

-

Symptom

Improper selection and layout of accessories can easily lead to scraping or even collisions during the picking process.

-

Solution

-

In the early stages of gripper design, the installation of components such as duct connectors and electrical connectors at the end of the gripper, as well as the layout of cables and ducts, should be comprehensively considered.

-

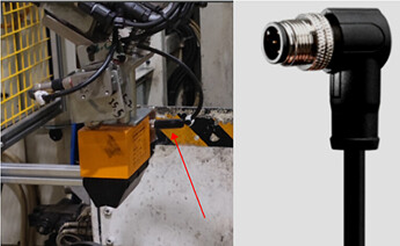

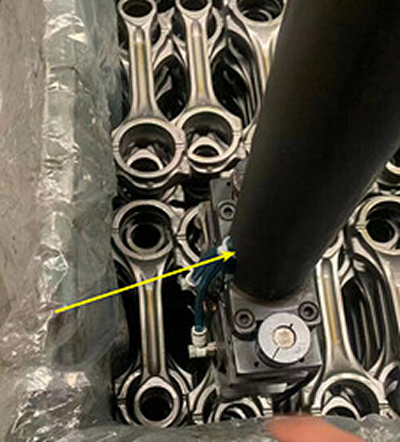

For components such as quick plugs or M12 connectors, it is recommended to route wires from the top. If side routing is necessary, “L”-shaped terminals should be used whenever possible.

-

The layout of cables and ducts should be as compact as possible, and the internal space of the gripper may be utilized.

-