Robot Interface Configuration

In this tutorial, you will learn how to load the Master-Control program files to the ABB robot and configure the Master-Control communication.

|

Preparation

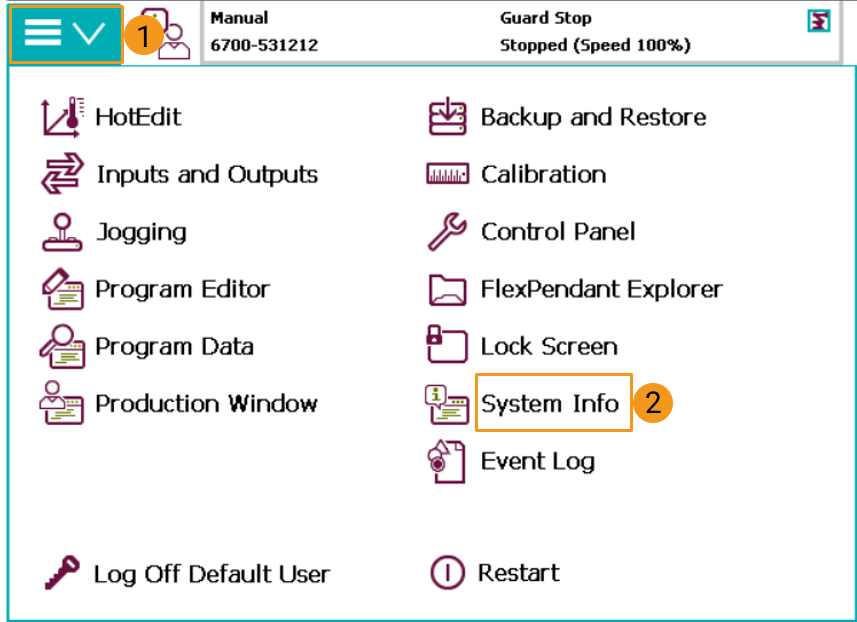

Check the Controller and RobotWare Version

-

Make sure that D652 or DSQC1030 IO board has been installed on the robot controller.

-

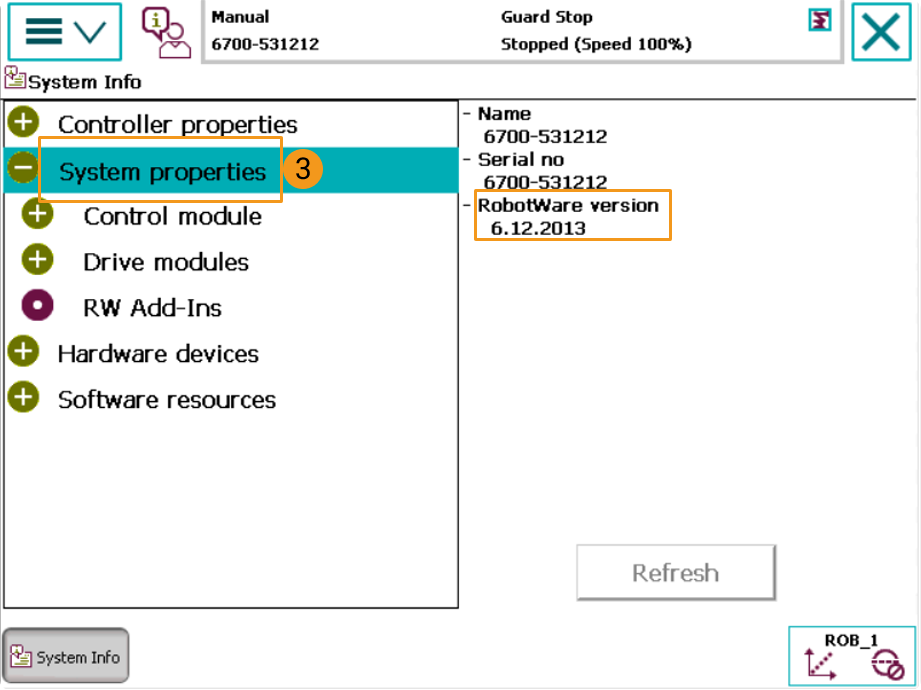

Confirm that the RobotWare version is 6.0 or above on the teach pendant.

-

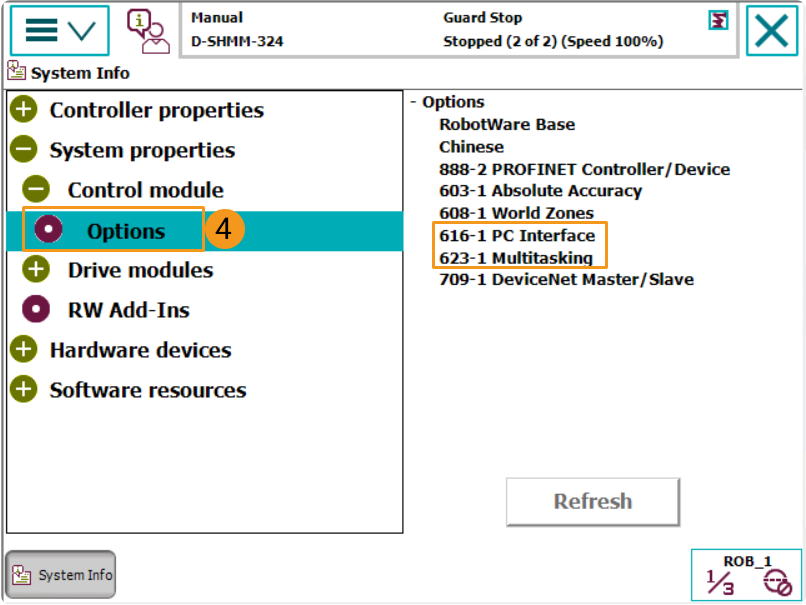

Confirm that the following control modules have been installed on the teach pendant.

-

623-1 Multitasking

-

616-1 PCInterface

-

|

If the preceding conditions cannot be met, the vision side cannot communicate with the robot through the master-control mode. Please contact the vendor of your robot. |

Reset the Robot System

After checking the software and hardware status of the controller, reset the robot system. If you are using a new robot, skip this section.

| Resetting the system will restore the factory settings. Please make sure that you have completed the backup operation. |

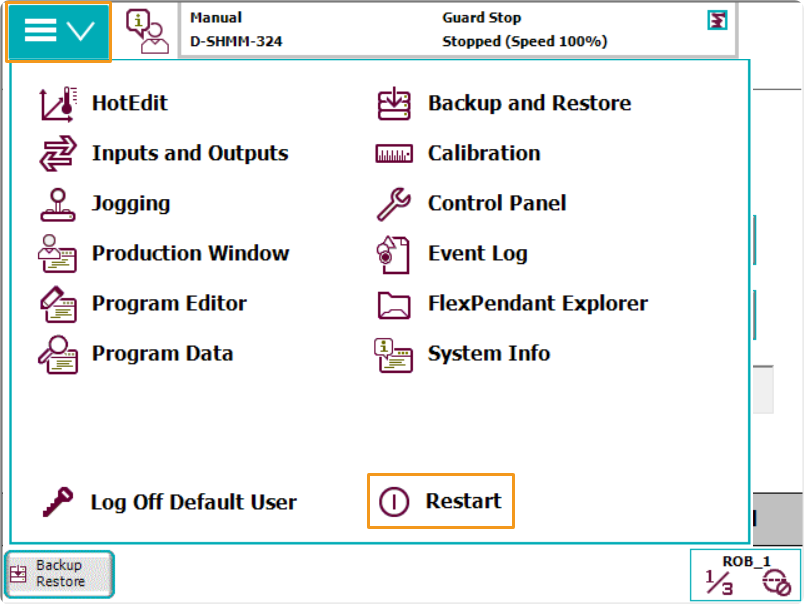

To reset the robot system, follow these steps:

-

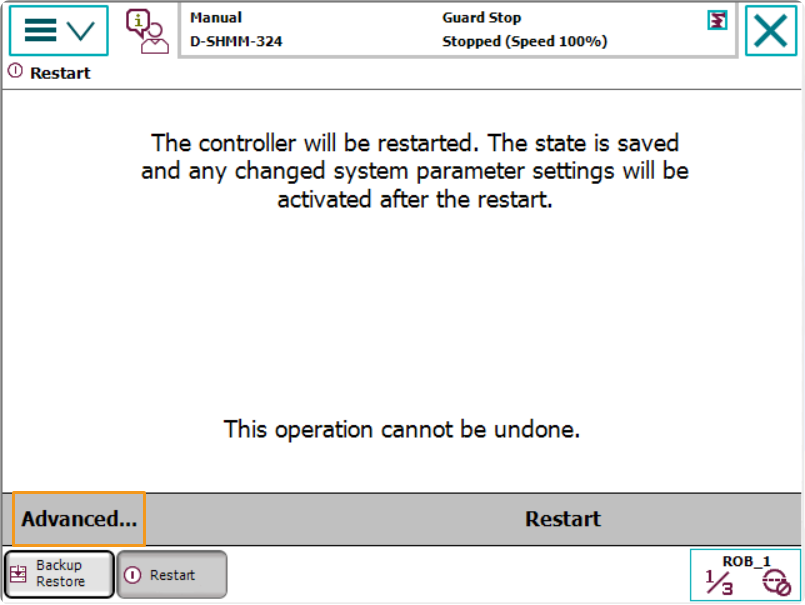

On the teach pendant, go to the home page using the menu in the upper-left corner, and then press Restart.

-

Press Advanced….

-

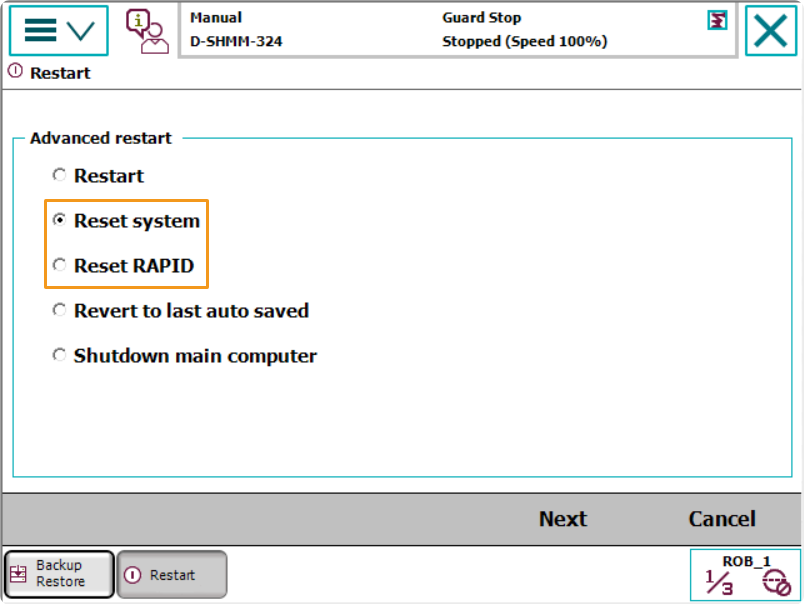

Select Reset system and then press Next.

-

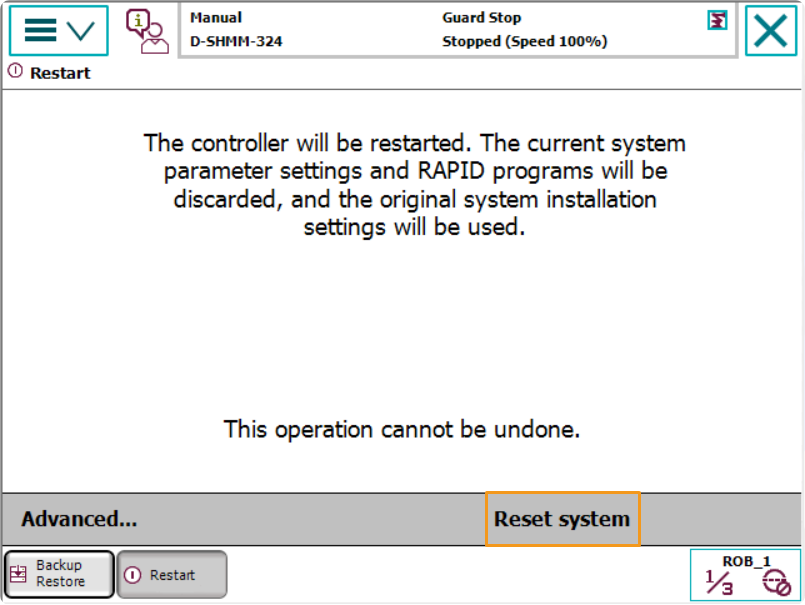

Press Reset system.

| Resetting the system takes 1 to 2 minutes. Resetting is completed when the home page is displayed again on the teach pendant. |

Connect the Network

-

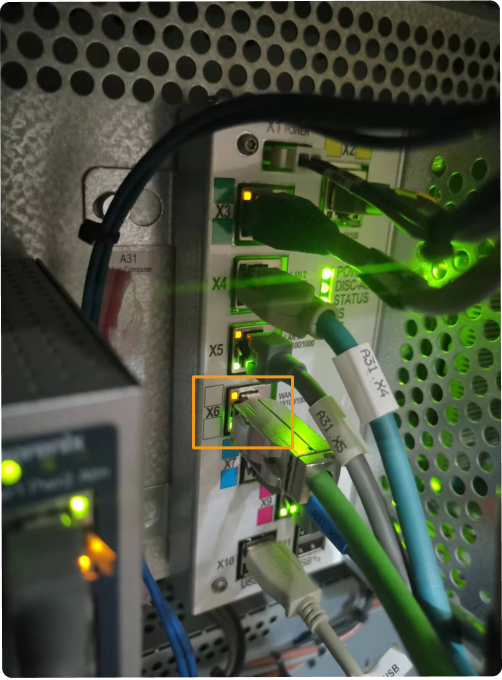

Connect the IPC Ethernet Cable to the X6 (WAN) port on the robot controller, as shown below.

-

Make sure that the IP address of the ABB robot and that of the IPC are in the same subnet.

Prepare the Program Files

-

On the IPC, open the

Mech-Center/Robot_Server/Robot_FullControl/abb/server on ABBfolder of the Mech-Mind Software Suite’s installation directory. -

Copy this folder to the USB flash drive, and insert it into the computer installing the RobotStudio software.

RobotStudio is the simulation and offline programming software for ABB robots. This software can be installed on the IPC or another computer. In this example, RobotStudio is installed on another computer.

File description:

-

“MM” folder: includes the robot program modules.

-

“config”: robot configuration files.

-

If the D652 IO board is used on site, you should use the D652.cfg and SYS.cfg files.

-

If the DSQC1030 IO board is used on site, you should use the DSQC1030.cfg and SYS.cfg files.

-

If neither the D652 IO board nor the DSQC1030 IO board is used on site, you should use the EIO.cfg and SYS.cfg files.

-

Load the Program Files to the Robot

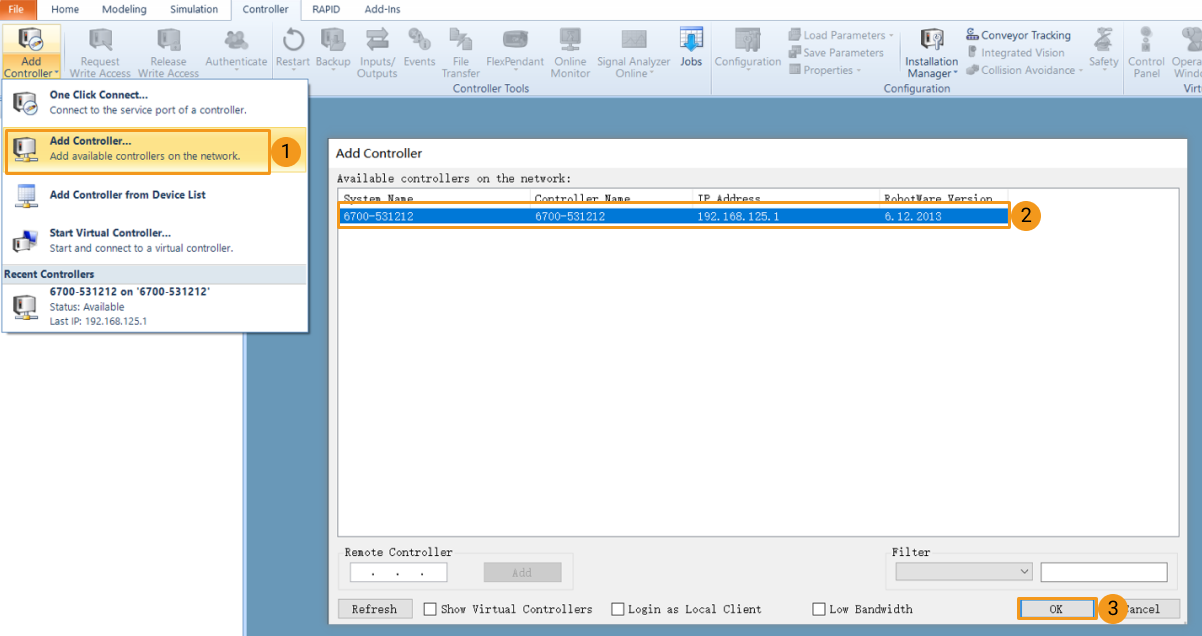

Open RobotStudio and Connect to the Controller

Click the Controller menu of RobotStudio, and select on the toolbar. In the prompted Add Controller dialog box, select the controller, and click the OK button.

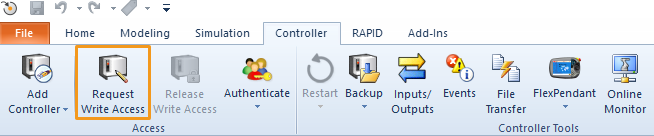

Obtain Write Access to the Robot

-

On the toolbar, click Request Write Access to request the write access to the teach pendant.

-

In the prompted Request for Write Access dialog box on the teach pendant, tap Grant.

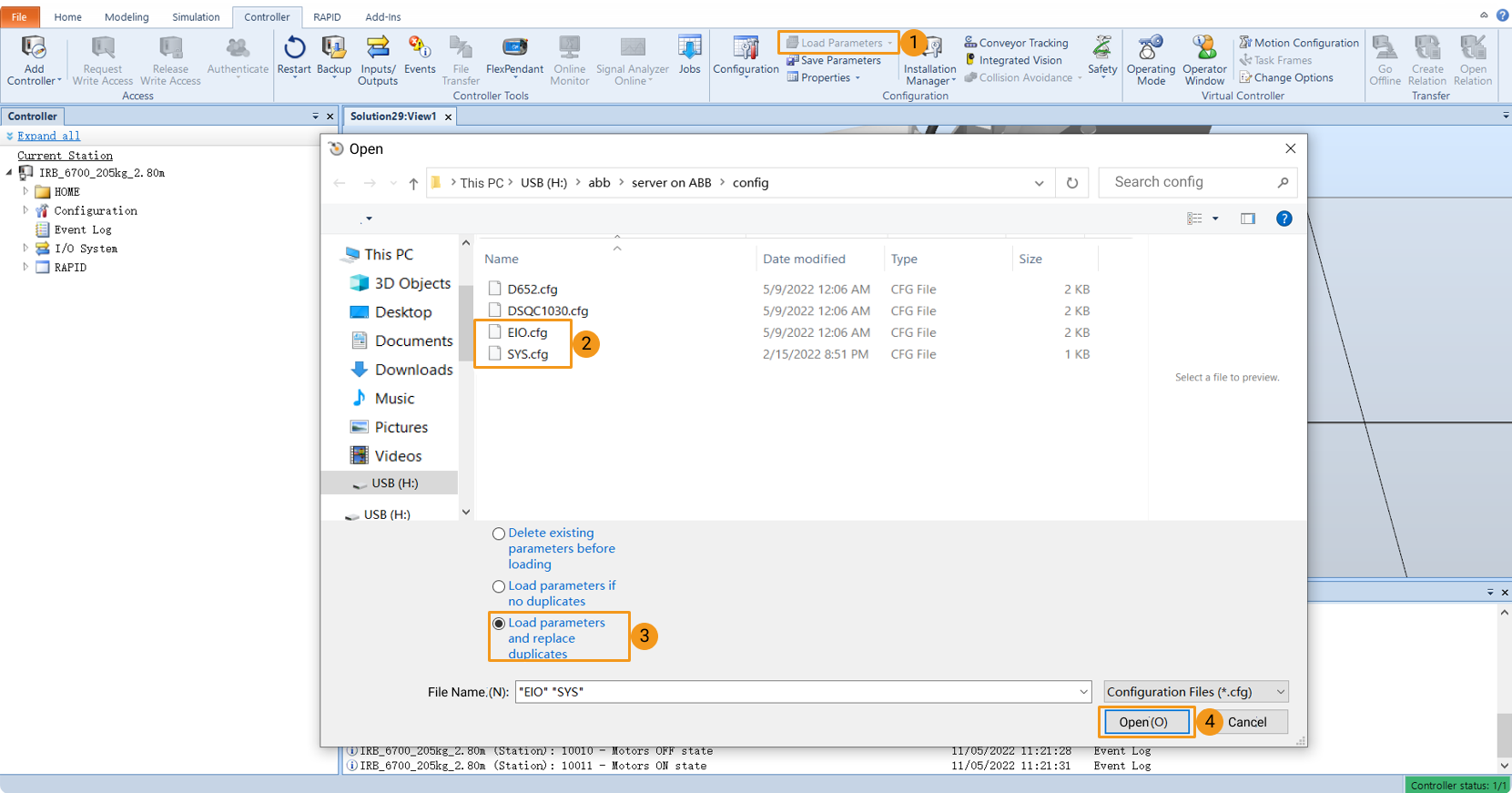

Load the Robot Configuration Files

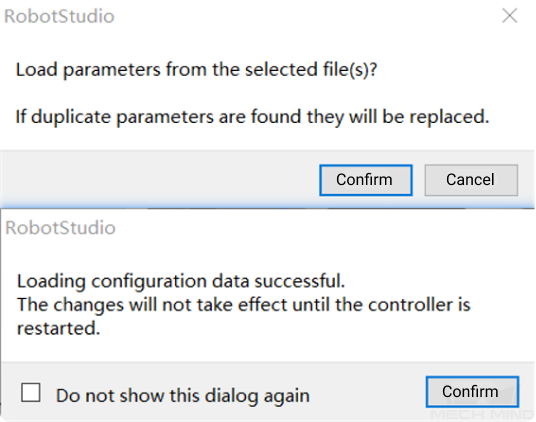

-

Click the Controller menu of RobotStudio, and select Load Parameters on the toolbar. Select the configuration files to import from the USB flash drive, select the Load parameters and replace duplicates radio button, and then click the Open button.

-

In the prompted dialog boxes, click Confirm.

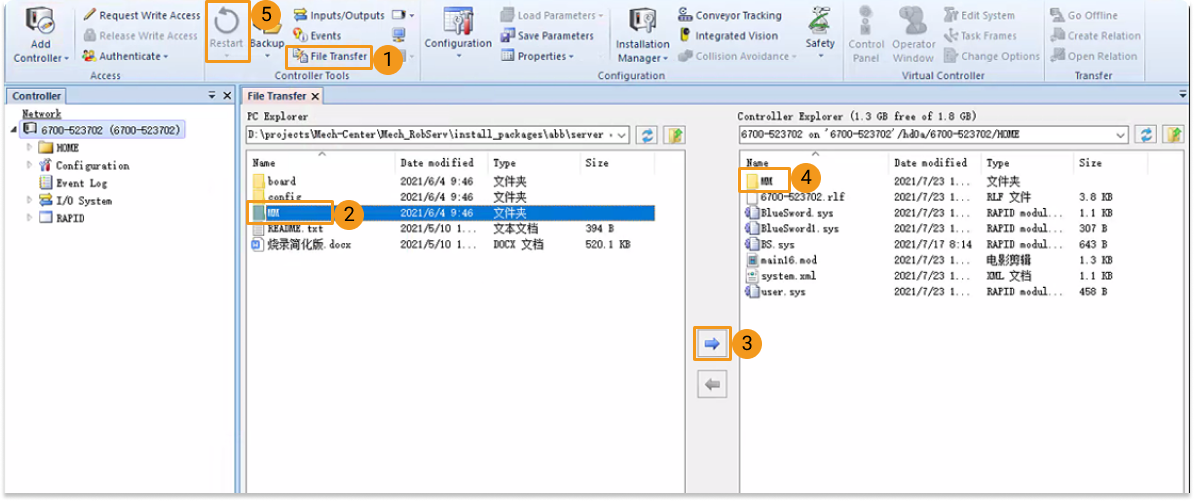

Load the Robot Program Modules

-

Click the Controller menu of RobotStudio, and select File Transfer on the toolbar. On the left panel of the File Transfer interface, select the “MM” folder, and then click the Transfer button to transfer this folder to the HOME directory of the robot system.

-

Click the Controller menu of RobotStudio, and select Restart on the toolbar to restart the robot system.

Till now, you have loaded the master-control program and the configuration files to the robot.

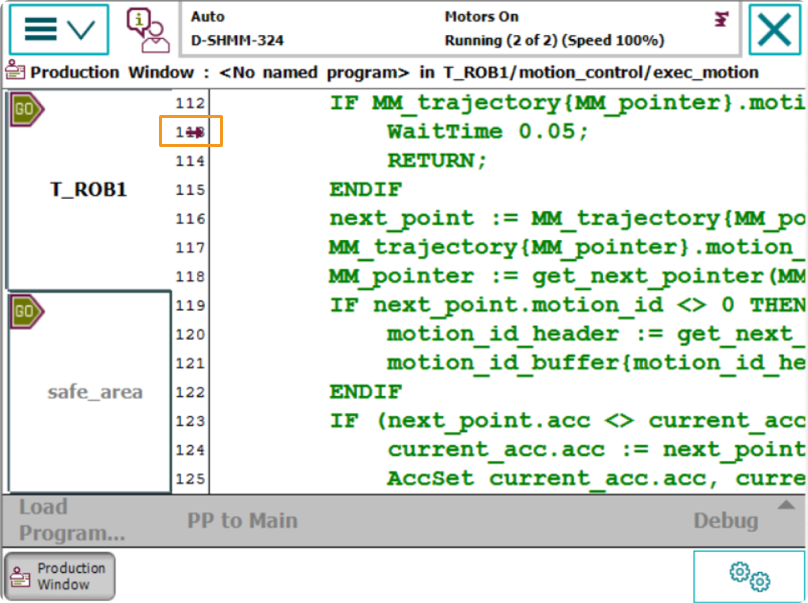

Test Whether Master-Control Communication Can Be Established

After the robot system has been rebooted, perform the following steps to test whether the master-control communication can be established with the robot:

Switch the Robot to Automatic Mode

-

In the robot controller, switch the robot to the automatic mode by using the switch key.

-

In the prompted dialog box on the teach pendant, tap Confirm.

-

In the robot controller, press the motor power button to power up the robot. When the robot is powered on, this button is solid on.

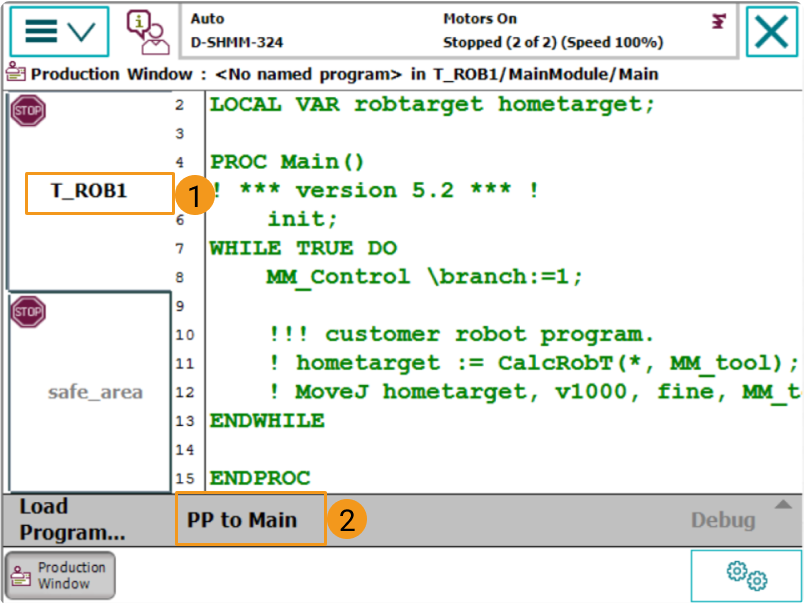

Run the Main Program

-

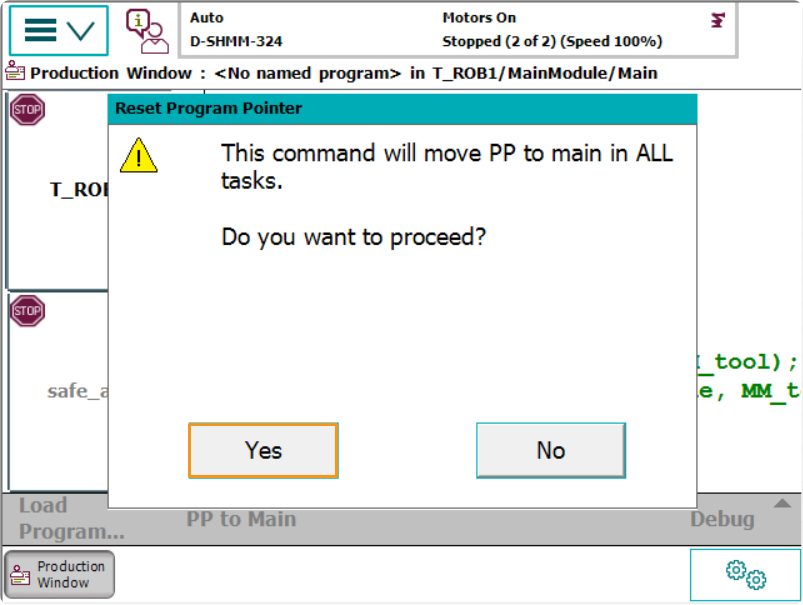

On the teach pendant, move the PP of tasks T_ROB1 to main, and tap PP to Main.

-

In the prompted dialog box, click Yes.

-

Press the run button on the right of the teach pendant.

Create a Mech-Viz Project

-

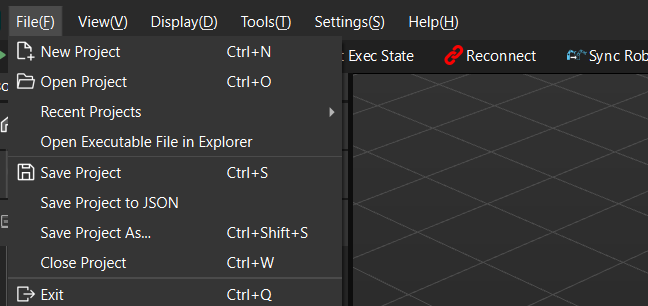

Open Mech-Viz, select .

-

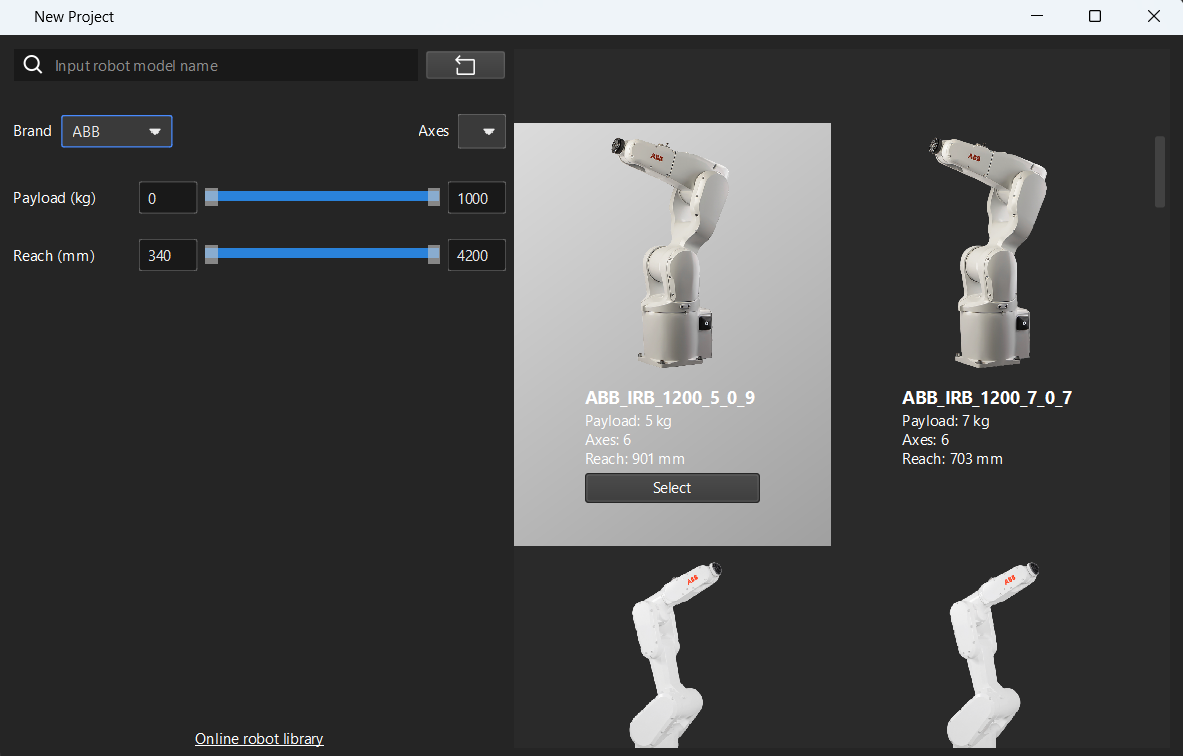

Set Brand to “ABB”, select the robot model “ABB_IRB_1300_11_0_9” on the right panel, and then click Select.

-

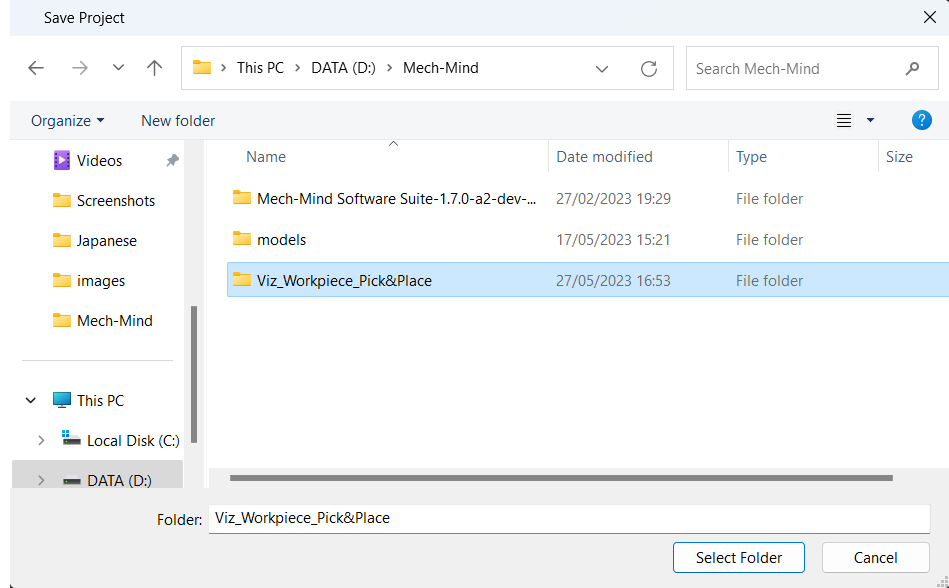

Press Ctrl + S, create a new folder named “Viz_Workpiece_Pick&Place”, select it, and then click Select folder.

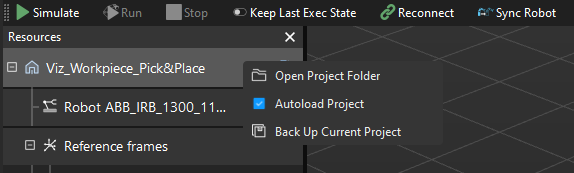

After the Mech-Viz project is saved successfully, in the Resources panel, the project name is displayed as “Viz_Workpiece_Pick&Place”.

-

Right-click the project name, and select Autoload project checkbox.

-

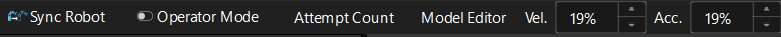

For the robot motion safety, on the toolbar, set Vel. (velocity) and Acc. (acceleration) to a small value, such as 5%.

-

Press Ctrl + S to save the project.

Configure Master-Control Communication Settings on Mech-Center

-

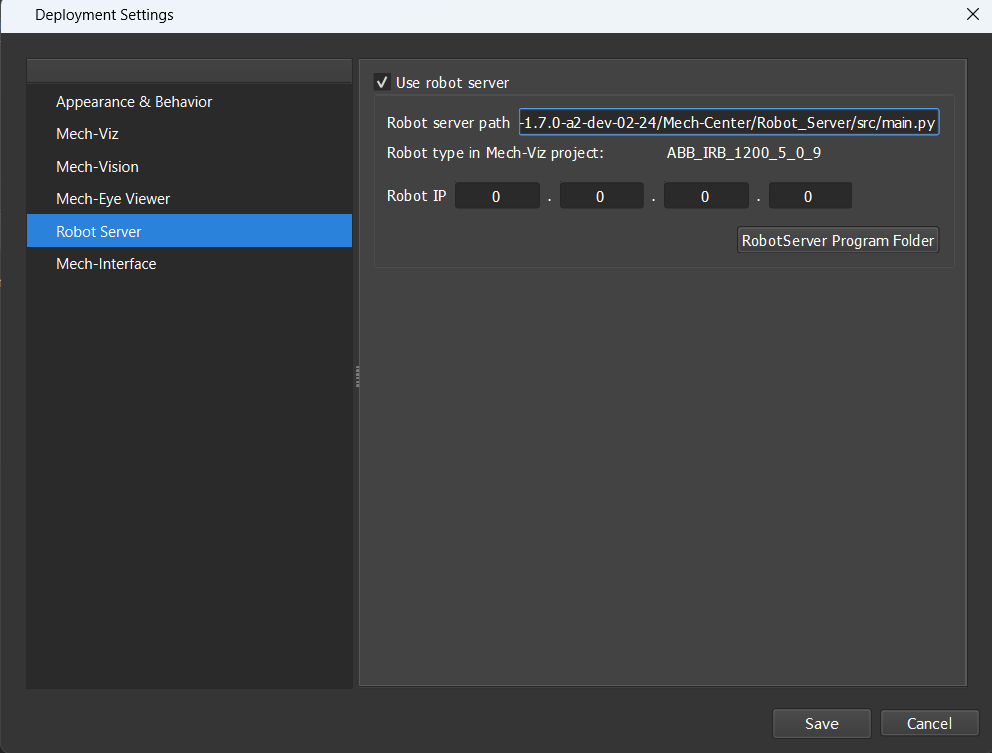

Open Mech-Center, select , and then select Enable Robot Server checkbox.

-

Make sure that the robot model matches the real robot, set Robot IP to the IP address of the real robot, and then click Save.

Connect to the Robot

In Mech-Center, click Connect Robot ![]() on the toolbar.

on the toolbar.

-

If the robot is successfully connected, a robot icon with the robot model will be displayed in the Service Status bar, and the corresponding message is printed in the Log panel.

-

If the connection fails, please check if any of the operations so far was incorrect.

Move the Robot

-

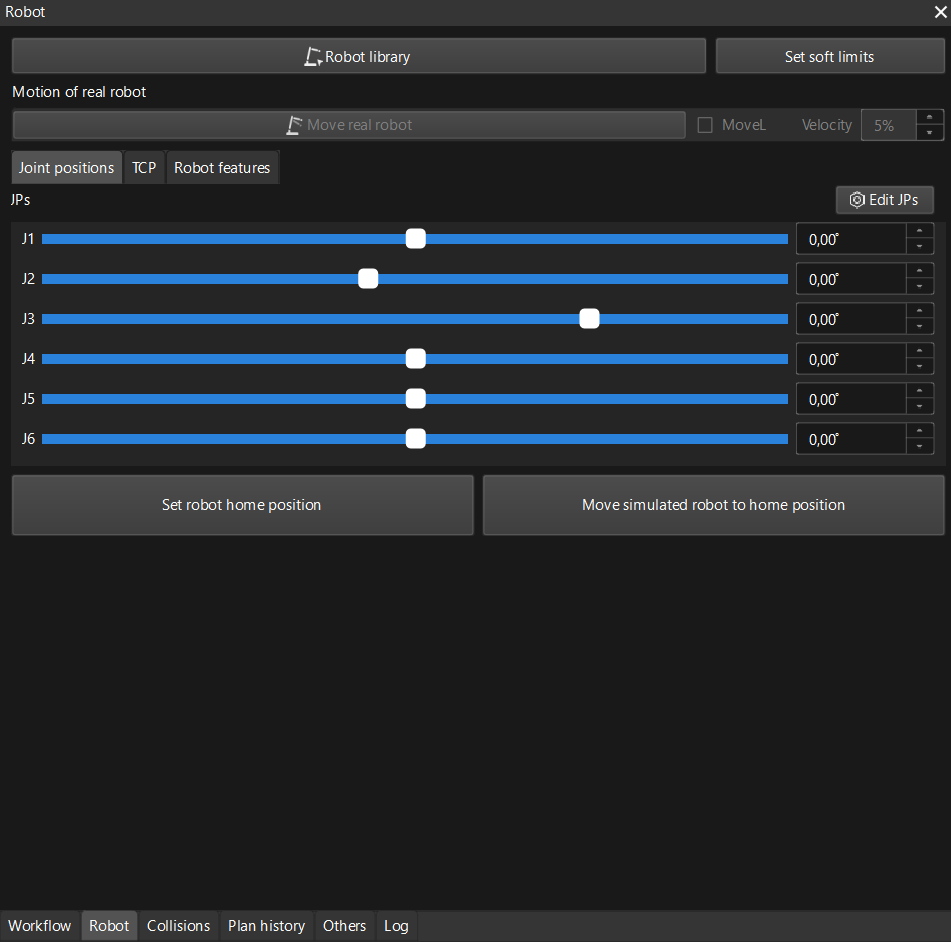

In Mech-Viz, click Sync Robot in the toolbar to synchronize the pose of the simulated robot to that of the real robot. Then, click Sync Robot again to disable the synchronization.

-

On the Robot tab, change the joint position of J1 slightly (for example, from 0° to 3°). The simulated robot will move accordingly.

-

Click Move real robot.

When moving the robot, please ensure the safety of personnel. In the case of an emergency, press the emergency stop button on the teach pendant! If you observe that the real robot moves to the pose of the simulated robot, the master-control communication has been established successfully.