Overlapping Planar Workpiece Loading¶

In overlapping planar workpiece loading scenario, the number of the workpieces to be processed is large and their size is small. In this project, deep learning algorithms and 3D matching algorithms are used to recognize the overlapping planar workpieces.

In actual projects, the top and bottom surfaces of some types of workpieces are dissimilar, and therefore the algorithms need to distinguish the top surface from bottom surface during picking. For other workpieces, their top and bottom surfaces are similar, and there is no need to distinguish the two surfaces during picking. This section focuses on the latter case where the algorithms do not need to distinguish the top surface from bottom surface of workpieces.

If a super model of the typical workpiece is available, it can be used in the project directly without deep learning training. You can contact the technical team to inquire if there is an available super model.

Create a New Typical Application Project¶

Create a Project¶

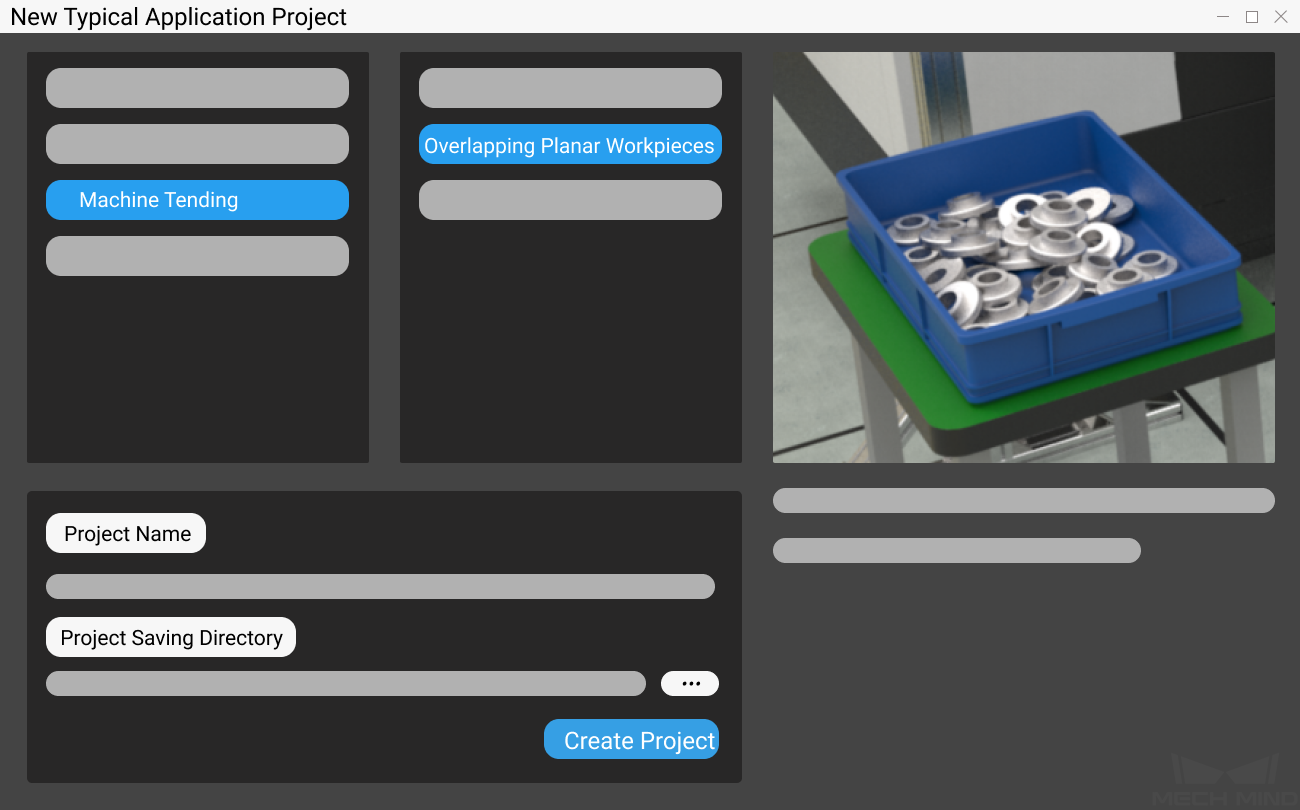

Click on in the Menu Bar or New Typical Application Project in the Toolbar to open the following window.

Select Overlapping Planar Workpieces.

Name the project.

Click on

to select a folder to save the project (it is recommended to create an empty folder), then click Create Project .

to select a folder to save the project (it is recommended to create an empty folder), then click Create Project .

Preparation¶

1. Calibrate the Camera¶

Calibrating the camera is to obtain the parameter file of the camera, which is used to determine the spatial relationship between the robot and camera.

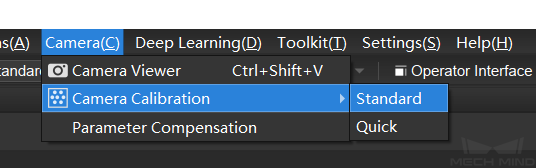

Click on Camera Calibration(Standard) in the Toolbar to calibrate the camera.

Alternatively, you can click on in the Menu Bar to open the same window.

For more information about camera calibration, please refer to Start Calibration - Standard Mode.

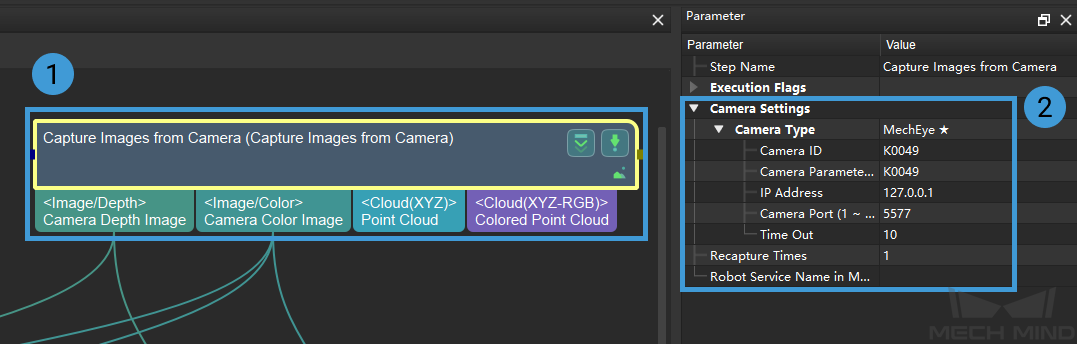

2. Configure the Camera¶

Before using the camera to capture images, you need to set the type, parameter group name, IP address and other parameters of the camera. For detailed instructions, please see Capture Images from Camera.

3. Set 2D and 3D ROI¶

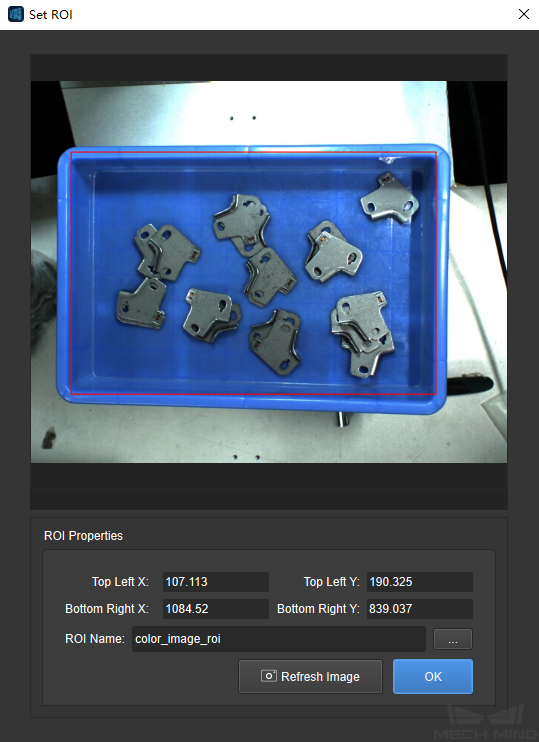

Double click on the Procedure Instance Segmentation to display the detailed structure, and set 2D ROI in the Step Scale Image in 2D ROI.

Setting a 2D ROI can avoid generating unnecessary point cloud and therefore increase the pre-processing speed. Please refer to Instructions for Setting 2D ROI for detailed instructions on setting 2D ROI.

Attention

The way to set a 2D ROI in Step From Depth Map to Point Cloud of the Procedure Point Cloud Pre-Processing is the same as above.

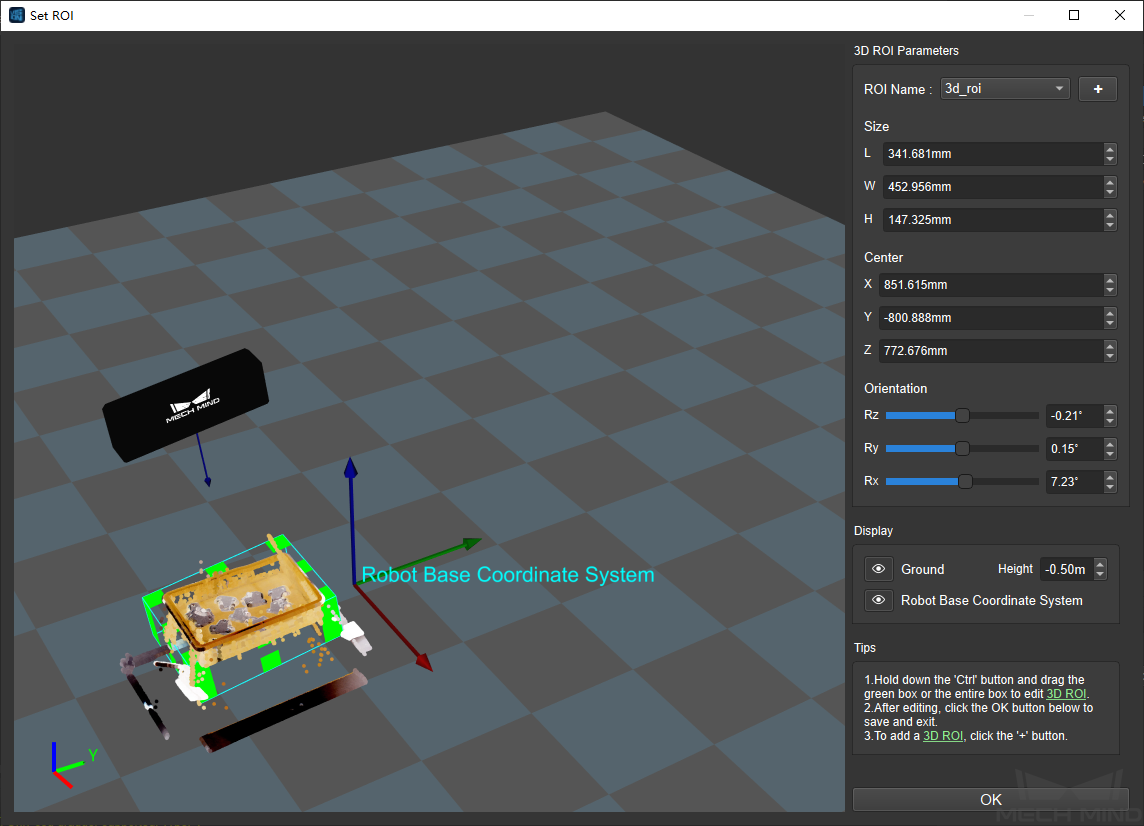

Double click on the Procedure Point Cloud Pre-Processing to display the detailed structure, and set 3D ROI in the Step Extract 3D Points 3D ROI.

Setting a 3D ROI can extract the point cloud of the target objects and filtered the unwanted points in the backgroung. Please refer to Instructions for Setting 3D ROI for detailed instructions on setting 3D ROI.

1. Instance Segmentation¶

Note

If you already have a super model, you can skip this step and start configuring the deep learning model file.

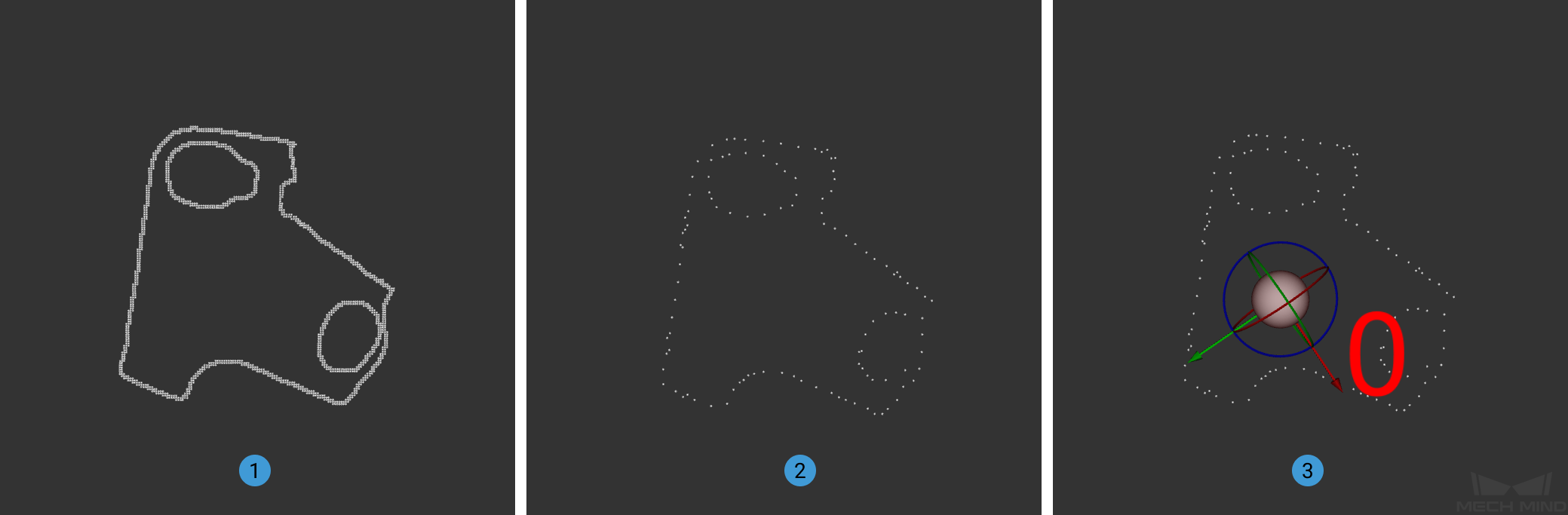

Instance segmentation is used for detecting and locating each distinct target object in an image, as shown below.

Please see Instance Segmentation for detailed information about training a deep learning model.

5. Generate a Model Point Cloud¶

Please use the tool Matching Model and Pick Point Editor to generate a model point cloud of the target object, so that Mech-Vision can compare the point cloud of the target object to the model point cloud and then generate an actual picking pose.

The model point cloud and pick point generated using the Matching Model and Pick Point Editor are shown below.

① is the generated point cloud model of the overlapping planar workpiece; ② is the downsampling result; ③ is the pick point.

The generated model file will be saved in the project folder.

Project Deployment¶

During project deployment phase, you will need to set relevant parameters of Steps, and add the configuration files obtained in the preparation phase to corresponding Steps before actually running the project.

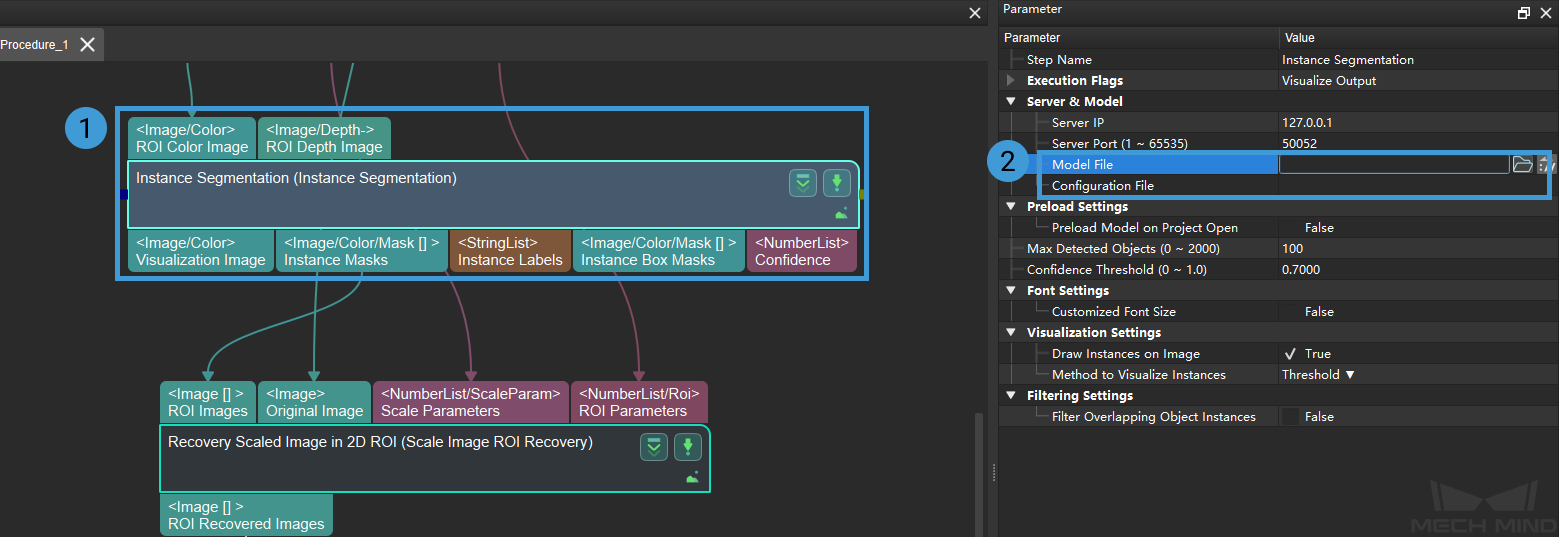

1. Set the DL Model File and Configuration File¶

Double-click on the Procedure Instance Segmentation to display the detailed structure.

Select the Step Instance Segmentation and click on

to set the model file and configuration file in the Parameter, as shown below.

to set the model file and configuration file in the Parameter, as shown below.

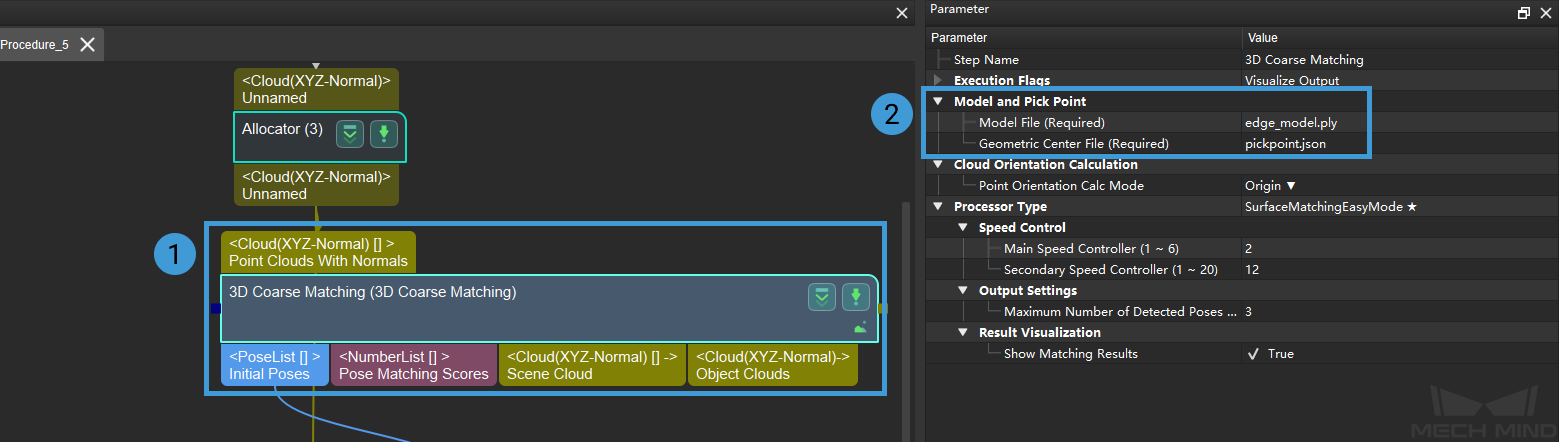

2. Set the Model File and Geometric Center File¶

Double-click on the Procedure 3D Matching to display the detailed structure.

Select the Step 3D Coarse Matching and click on

to set the model file and geometric center file in the Parameter, as shown below.

to set the model file and geometric center file in the Parameter, as shown below.

The way to set model file and geometric center file in 3D Fine Matching is the same as it is in 3D Coarse Matching.

Click to see the example of each file

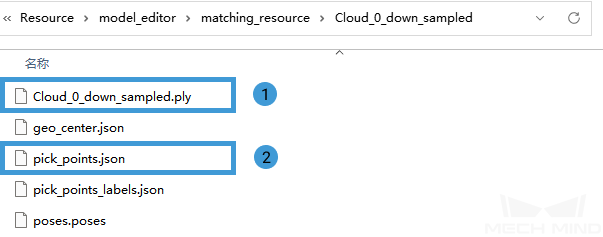

① is a point cloud model file, and ② is a geometric center file.¶

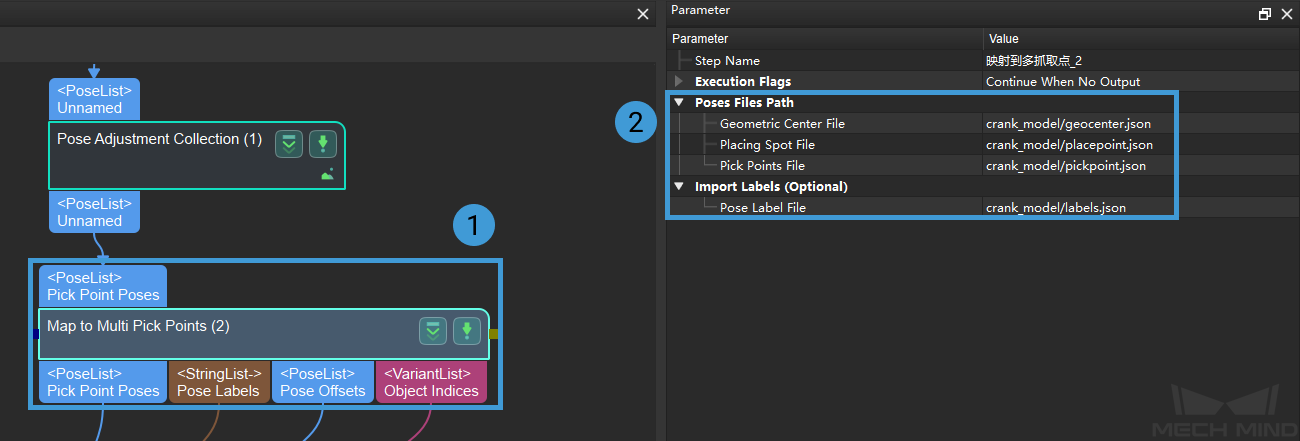

3. Set Poses Files¶

Select the Step Map to Multi Pick Points and click on

to set the poses files and important lables in Parameter, as shown below.

to set the poses files and important lables in Parameter, as shown below.

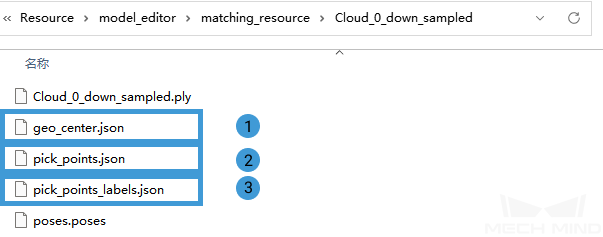

Click to see the example of each file

① is a geometric center file, ② is a placing spot file, and ③ is a pose label file.

Running and Debugging¶

After completing the project deployment, click on ![]() to run the project.

to run the project.

Please see Run the Project and Debug for how to run and debug the project.

Please see Overlapping Planar Workpiece Loading to learn about the algorithms and parameter adjustment of the project.

After successfully running and debugging the project, if you need to save the on-site data for future reference or you find that certain part of the project is not performing well and would like to optimize the Step or tune the parameters in an off-site situation, the tools Data Storage and Data Playback can be very useful.

Prerequisites for using the tool Data Playback:

A project file in which the project can run correctly without errors.

On-site source data which is gathered during the whole period while running the project, including 2D color images, depth maps, camera parameter file. Please refer to Data Storage for instructions on how to save the data.