Gripper Design

This section introduces the gripper design in single-case carton depalletizing solution, including gripper selection and gripper-related component selection.

Gripper Model Selection

Generally, a vacuum gripper will be used to pick the cartons. In this case, the characteristics of the carton and the cycle time requirements of the project need to be considered to ensure the stability and effectiveness of suction. Common vacuum grippers currently in use include polyurethane foam vacuum grippers and bellows suction cups.

Foam Vacuum Grippers

Foam vacuum grippers are often used in scenarios where multiple types of cartons or cartons with packing tapes on their surfaces need to be picked. The specific advantages are as follows:

-

Foam vacuum grippers are versatile, adapting well to surfaces with varying degrees of flatness, making them ideal for picking cartons that may not have completely flat surfaces.

-

The foam vacuum grippers show resilient suction force when picking cartons, suitable for picking cartons with an offset center of gravity.

|

Due to the on-site environment and frequency of use, the service life of the foam vacuum grippers may be influenced. Therefore, you should consider the actual situation on site. |

Bellows Suction Cups

Bellows suction cups are often used when there are relatively few types of cartons, and there is no packing belt on the surface of the carton or the suction cups can avoid the packing belt. Bellows suction cups are relatively economical and efficient, and their specific advantages are as follows:

-

Bellows suction cups have a longer service life.

-

Bellows suction cups provide a stable and reliable suction effect. Using the bellows suction cups can reduce the contact between the suction cups and the packing belt on the carton surfaces.

Vacuum System Design

Principles of Design

The vacuum system design is very important for vacuum suction devices. Please refer to the following points when designing the vacuum system.

-

When the total weight of a single carton is between 1 kg and 20 kg, a vacuum generator is preferred to provide negative pressure.

-

When the total weight of a single carton is between 20 and 60 kg, it is generally recommended to use a vacuum pump or vacuum blower to provide negative pressure.

Extension of Knowledge

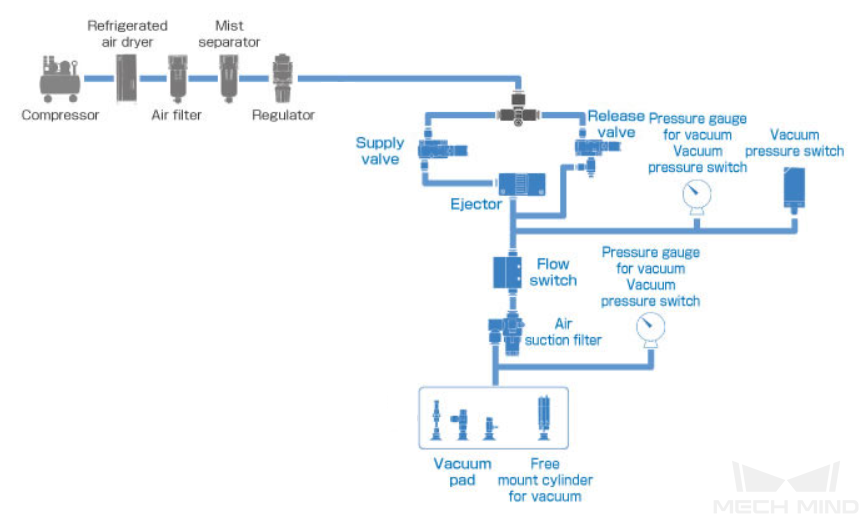

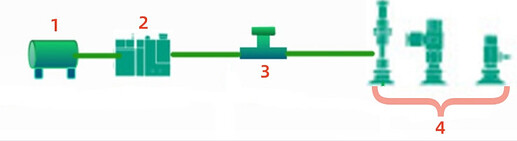

There is a big difference between the gas circuit design of a vacuum generator and a vacuum pump. The diagrams of the gas circuits are as follows.

-

The gas circuit system of the vacuum generator is shown in the figure below.

-

The gas circuit system of the vacuum pump or blower consists of a 1-vacuum pump, 2-control system, 3-check valve, and 4-suction cup.

Selection of Gripper-Related Components

Self-Closing Valve

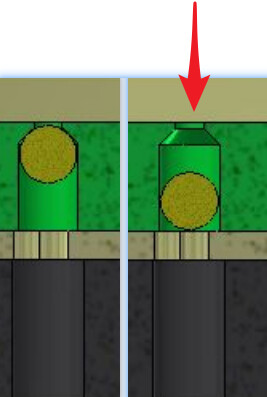

A self-closing valve is a common device usually used on foam vacuum grippers to control the on and off status of the suction cup. When any suction cup is not covered by the item to be picked, the self-closing valve can turn off the specific suction cup to prevent vacuum leakage and ensure that other suction cups can still function properly, thus creating sufficient vacuum to maintain picking stability.

Therefore, when using the offset picking function, it is important to ensure that the exposed suction cups are turned off and the self-closing valve is configured properly. This ensures that when picking smaller cartons, the vacuum gripper can still maintain sufficient negative pressure for stable and effective picking.

Vacuum Release Valve

To speed up vision cycle time and improve productivity, a vacuum release function is usually added to suction cups in actual projects. This device reduces the vacuum condition between the vacuum gripper and the carton by introducing compressed air, thus releasing the carton quickly.

When using vacuum grippers without a vacuum release, the carton can only detach from the vacuum gripper by its own weight. When the carton is light, it takes a longer time to detach from the vacuum gripper, which will affect the overall picking time. The vacuum release component accelerates the process of separating the carton from the vacuum gripper, making picking and placing more efficient and reducing time consumption.

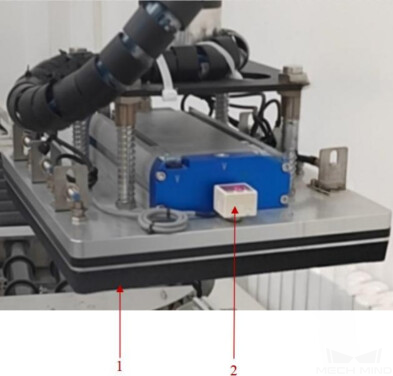

Vacuum Pressure Gauge

For carton-picking applications, you can set a predefined vacuum pressure threshold. If the vacuum pressure of the gripper is below this threshold, the robot will not pick until the vacuum pressure exceeds this threshold. This design ensures that the gripper is in proper working conditions and reduces unexpected picking failures or other problems.

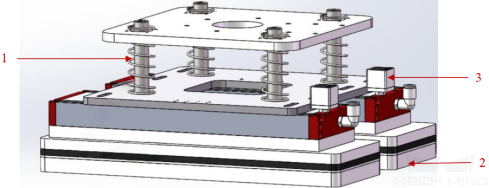

By utilizing the vacuum pressure gauge to monitor the vacuum gripper and setting a vacuum pressure threshold, you can easily monitor and maintain the device, ensuring the gripper functions properly. As shown below, 1 is the vacuum gripper, and 2 is the vacuum pressure gauge.

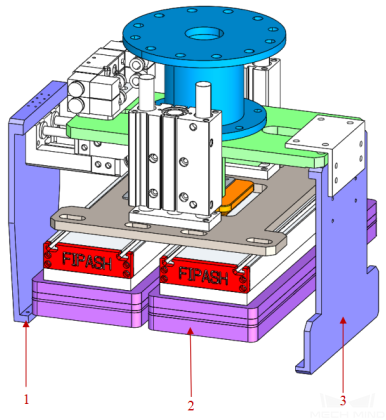

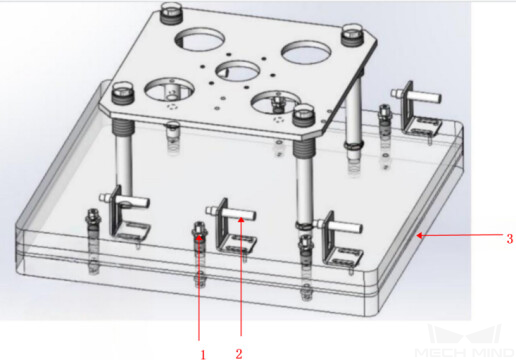

Box Dropping Sensor

The box dropping sensor is an important component of the gripper. When a carton is dropped, the box dropping sensor will immediately detect it and notify the host system to stop the robot. As shown in the figure below, 1 is the detection rod, 2 is the box dropping sensor, and 3 is the foam.

Gripper Pipes

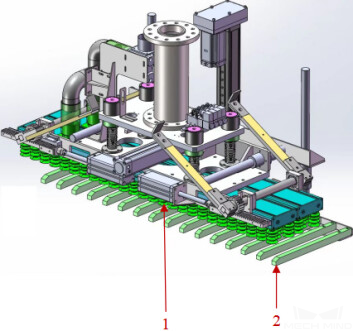

The air flow required by the vacuum generator is relatively small, and common PU pipes are often used. The diameter of the pipes is usually less than 20 mm, as shown in the left figure below.

For vacuum pumps and vacuum blowers, their installation and use is relatively complicated. Usually, hoses with wire support are used, and the diameter of the hose is usually greater than 30 mm, as shown in the right figure below.

Gripper Protection Device Design

After the vacuum gripper picks up the carton, it will be affected by the acceleration, deceleration or emergency stop of the robot, and there is a risk that the carton will be dropped. For demanding scenarios, such as cartons containing liquor, glass-packaged pharmaceuticals, cigarettes, etc., mechanical structures are usually used to improve the reliability of carton picking. The common mechanical structures are as follows.

| Type | Illustration | Structure description |

|---|---|---|

Clamping-type protection device |

|

1-Left sliding clamp finger

|

|

1-Left clamp plate

|

|

Bottom support protection device |

|

1-Bellows suction cup

|

Gripper cushioning |

|

1-Spring buffer

|

Multi-Pick Design for Gripper

When the gripper is used to pick multiple cartons at once, the gripper design requirements are as follows.

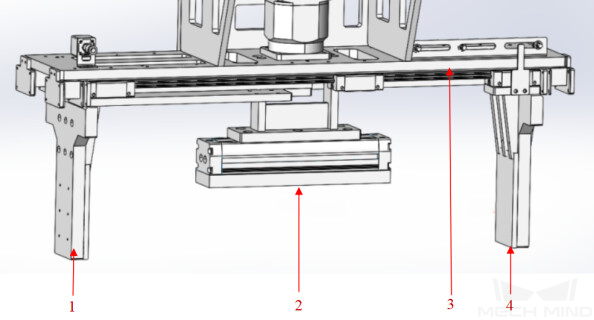

Pick Entire Layer

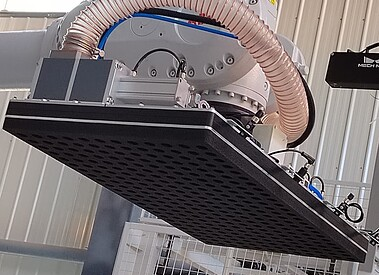

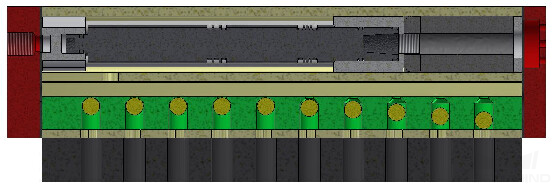

The vacuum gripper picks the entire layer of cartons at once, which results in a high picking efficiency.

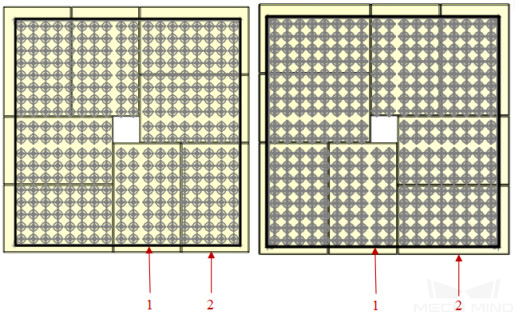

When designing the gripper, you need to consider the weight and suction area of each carton first, and then the overall picking and collision issues. For light, airtight, cartons with large adhesion areas, the stacking form may not be a critical consideration in gripper design. As shown below, 1 is the vacuum gripper, and 2 is the carton.

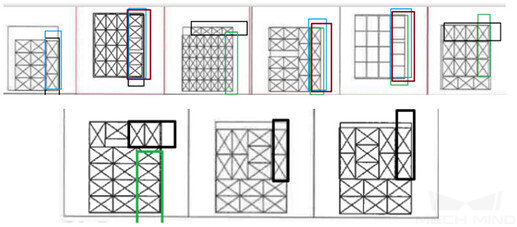

Pick Entire Row/Column

Pick multiple cartons in an entire row or columns.

When designing the gripper, you need to consider factors such as the carton’s own weight, material permeability, incoming pallet pattern, carton specifications, etc. As shown in the figure below, the boxes within colored frames can be grouped for multi-picking.