4. Picked Object Configuration¶

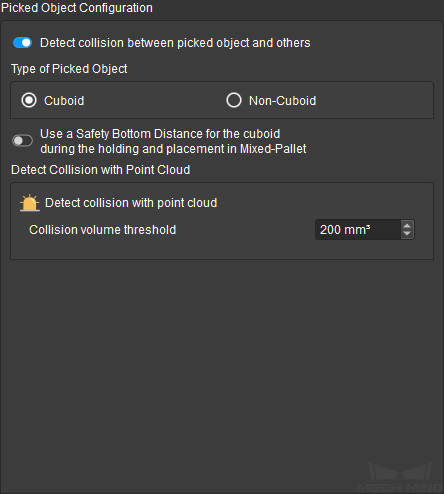

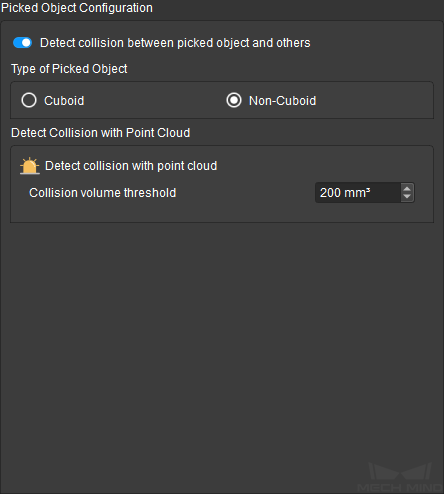

In this pane, you can enable and configure the detection of collisions between picked workobjects and other objects.

After enabling Detect collision between picked object and others, you can select the type of picked workobjects, and the parameters are automatically adapted to your selection.

Picked workobjects are divided into two types, cuboid and non-cuboid.

The following sections introduce each type and the correlated parameters separately.

4.1. Cuboid Picked Workobjects¶

Collision detection requires object models. Cuboid workobject models can be automatically generated by Mech-Viz if object dimensions in the format of Size3DList are received from Mech-Vision.

Mech-Vision Steps that can output object dimensions include Calc Poses and Dimensions of Rectangles, Calc Poses and Dimensions from Planar Point Clouds, Read Object Dimensions, etc. The generated object dimensions are sent to Mech-Viz through the Procedure Out Step.

4.1.1. Safety Bottom Distance¶

In palletization applications, the carton dimensions input to Mech-Viz may not be accurate enough, and the carton itself might deform when it’s pick up. These may result in inaccuracies in collision detection.

The safety bottom distance setting adds the set value to the obtained height dimension of the cuboid model during collision detection. This way, on the planned path, the bottom surface of the carton is in fact farther away from the whatever is below it, avoiding collision with palletized cartons.

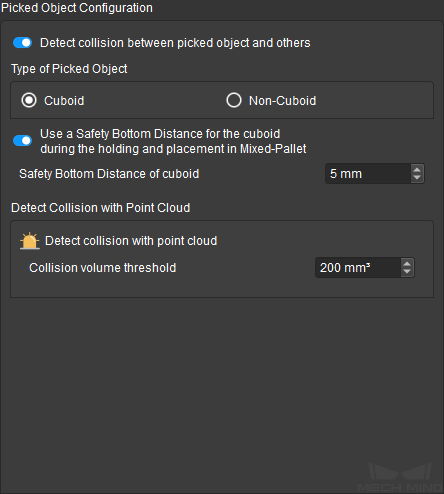

To set a safety bottom distance, please enable Use a Safety Bottom Distance for the cuboid during the holding and placement in Mixed-Pallet, and then adjust the value for Safety Bottom Distance of cuboid. The default value is 5 mm.

The setting is visualized in the 3D simulation area when you simulate or run the project. The following figure shows the picked cuboid model without a safety bottom distance (left) and with a safety bottom distance of 30 mm (right).

4.1.2. Detect Collision with Point Cloud (Cuboid)¶

Here you can set the collision volume threshold with point cloud.

Collision volume threshold: set how large a volume of the picked workobject is allowed to collide with the point cloud at a target pose.

The default value is 0 (no contact between the picked workobject and point cloud is allowed).

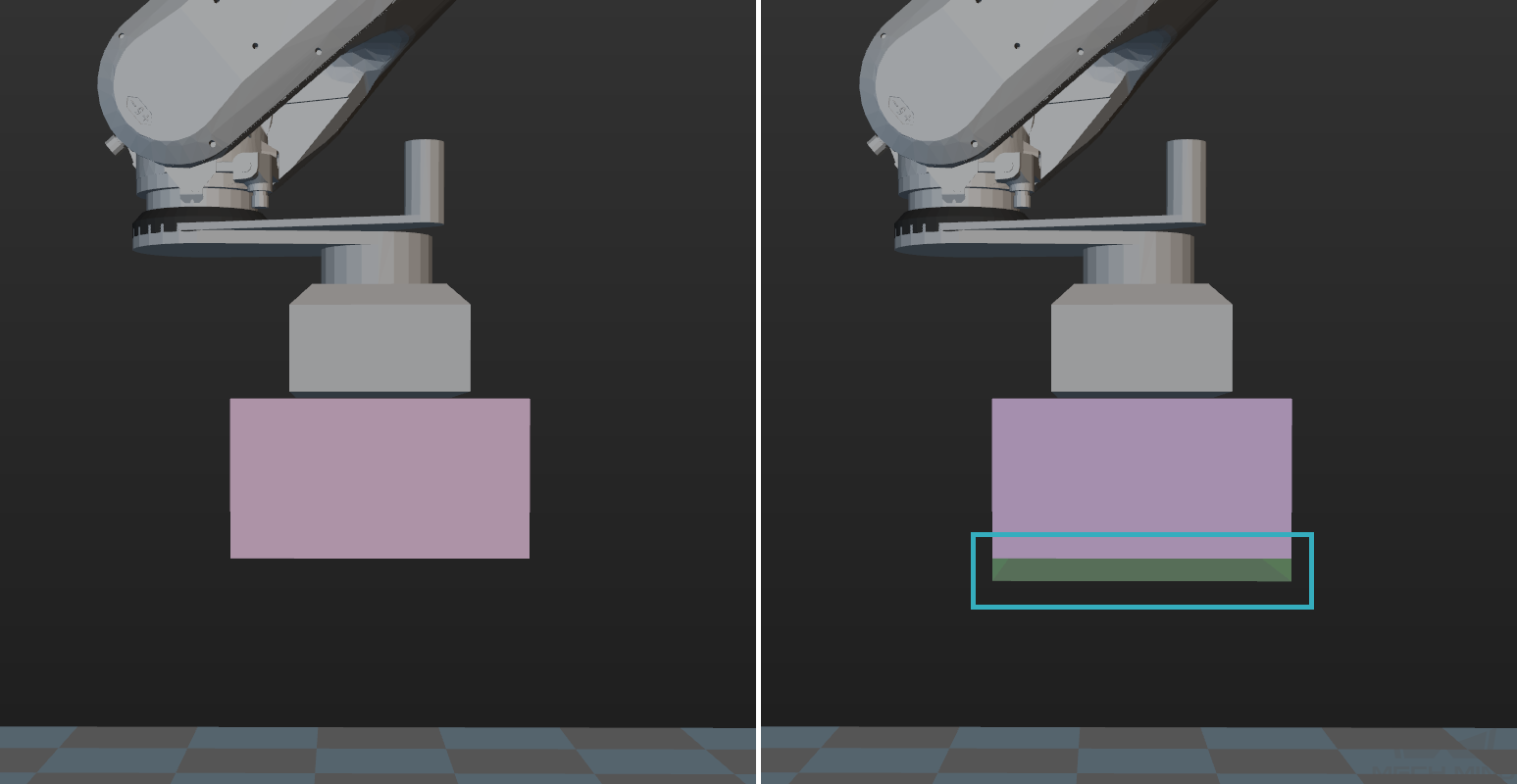

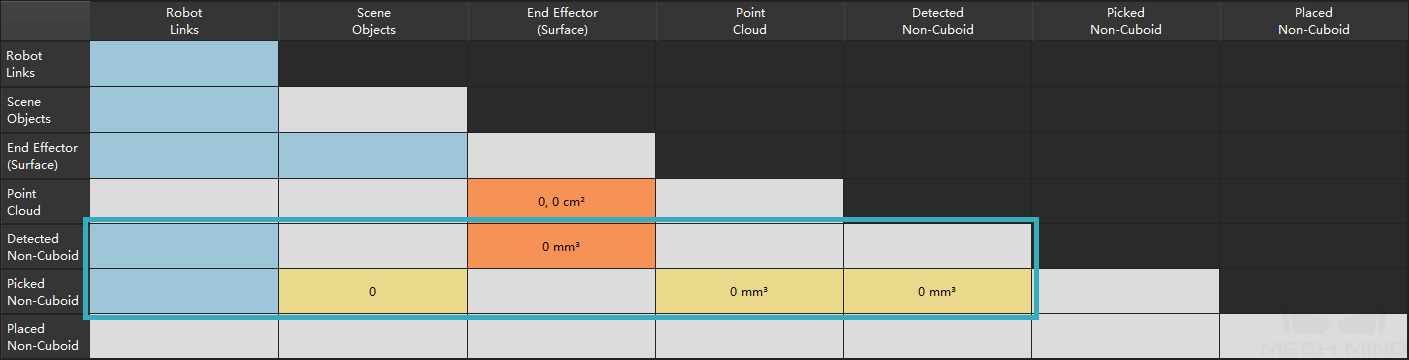

With Detect collision between point cloud and others (Cuboid) and Detect collision between picked object and others, the following object pairs are checked for collisions.

4.2. Non-Cuboid Picked Workobjects¶

Collision detection requires object models. Non-cuboid workobject models must be prepared beforehand and added to the Mech-Viz project folder.

Move the STL and BINVOX files of the workobject to the collision_models folder under the project folder.

Note

The file names must be identical to the pose label of the same object set in Mech-Vision.

In Mech-Vision Send Point Cloud to External Service Step, check Send Object Information.

4.2.1. Detect Collision with Point Cloud (Non-Cuboid)¶

Here you can set the collision volume threshold with point cloud.

Collision volume threshold: set how large a volume of the picked workobject is allowed to collide with the point cloud at a target pose.

The default value is 0 (no contact between the picked workobject and point cloud is allowed).

With Detect collision between point cloud and others (Non-Cuboid) and Detect collision between picked object and others, the following object pairs are checked for collisions.