Appendix¶

Use Mech-Viz for Collision Detection¶

If collision detection is required, please build the Mech-Viz project by referring to the sample project at Mech-Center/tool/viz_project/check_collision.

Please note:

check_collision is only a sample project. In the project, except for move Tasks, the Tasks in the workflow are not supposed to be deleted or modified in their positions in the workflow.

Please select the actual robot model in use for the project.

The move Tasks can be deleted, added, or modified according to the actual needs.

Use Mech-Viz for Controlling Suction Cup Sections or Array Gripper¶

If controlling multiple suction cup sections or an array gripper, please build the Mech-Viz project by referring to the sample project at Mech-Center/tool/viz_project/suction_zone.

Please note:

suction_zone”** is only a sample project. In the project, except for move Tasks, the Tasks in the workflow are not supposed to be deleted or modified in their positions in the workflow.

Please select the actual robot model in use for the project.

The move Tasks can be deleted, added, or modified according to the actual needs.

Please configure the suction cup file in the project.

DO list can only be obtained after image capturing.

Map String Labels to Integer Labels in Mech-Vision¶

The Step to map string labels to integer labels in Mech-Vision is Label Mapping.

Label mapping can be done by configuring a mapping file in the Step’s parameters. A sample label mapping file is as follows:

{

"Medium", "3",

"Large", "2",

"Small", "1"

}

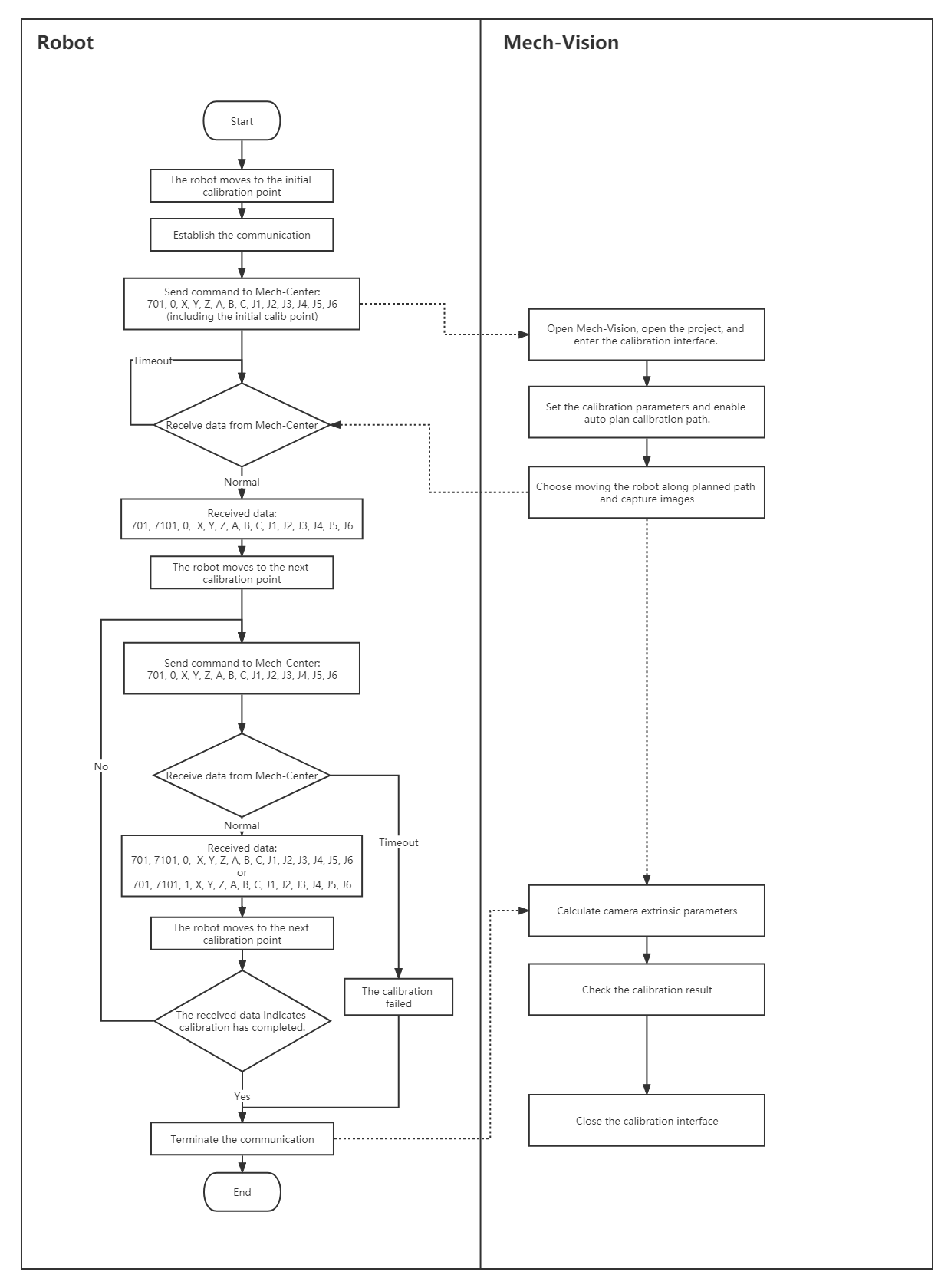

Flowchart of Calibration¶

Note

The robot pose sent and received can be either a flange pose ([X, Y, Z, A, B, C]) or JPs ([J1, J2, J3, J4, J5, J6]).

The last point sent from Mech-Vision is the initial calibration point input to Mech-Vision at first, telling the robot to move back to the initial position, and no image capturing will be performed for the last point sent.

In the data sent from Mech-Vision, the third argument (value: 0 or 1) indicates whether the calibration has finished. 0 means not finished and the next calibration point is on the way; 1 means the calibration has finished.

Add Signal for Exposure Completion in Mech-Vision¶

For Profinet and Ethernet/IP, a camera Exposure Complete signal can be used to shorten the system cycle time.

When the Mech-Vision project takes a long time to run, the system cycle time can be shortened by moving the robot immediately after camera exposure.

In the Mech-Vision project, please make the following modification to implement the Camera Exposure Complete signal:

Add a Notify Step, and connect it to the control flow port of the Capture Images from Camera Step.

For the Capture Images from Camera Step, set the parameter Trigger Control Flow When Output to True.

Name the Notify Step to “Standard Interface Notify”, and set the message content to “1001”. Please do not change the content later.

After the settings above, when the camera finishes exposure, an Exposure Complete signal will be sent, and please reset the signal using Exposure Complete Reset after receiving it.

If Mech-Center does not receive the reset signal for over 10 seconds, it will raise an error message: Mech-Center data confirmation signal timeout.