TM Setup Instructions¶

This section introduces the process of setting up master-control of a Techman (TM) robot.

Prerequisites¶

Before you perform any operation on the TM robot, please make sure that the following requirements have been met.

The controller software (TMflow) version is 1.84 or above.

The version of the Mech-Mind Software Suite you use is 1.6.1 or above.

You have known the IP address of the robot, e.g., 192.168.2.10.

Get Control of the Robot¶

There are two ways to control the robot, and you can choose either one according to the actual situation.

Control the Robot via the Controller¶

Connect the monitor, keyboard, and mouse to the controller through the controller’s USB and HDMI ports accordingly.

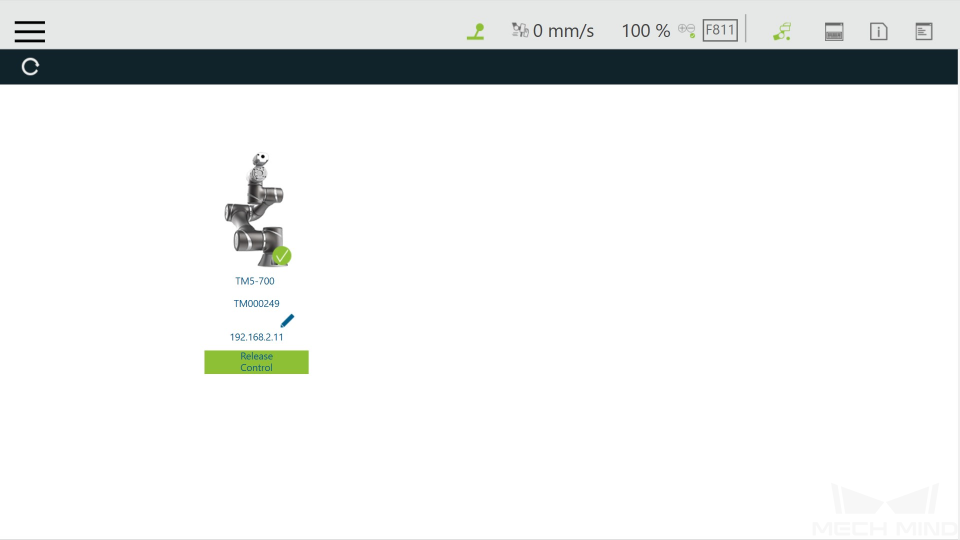

Click

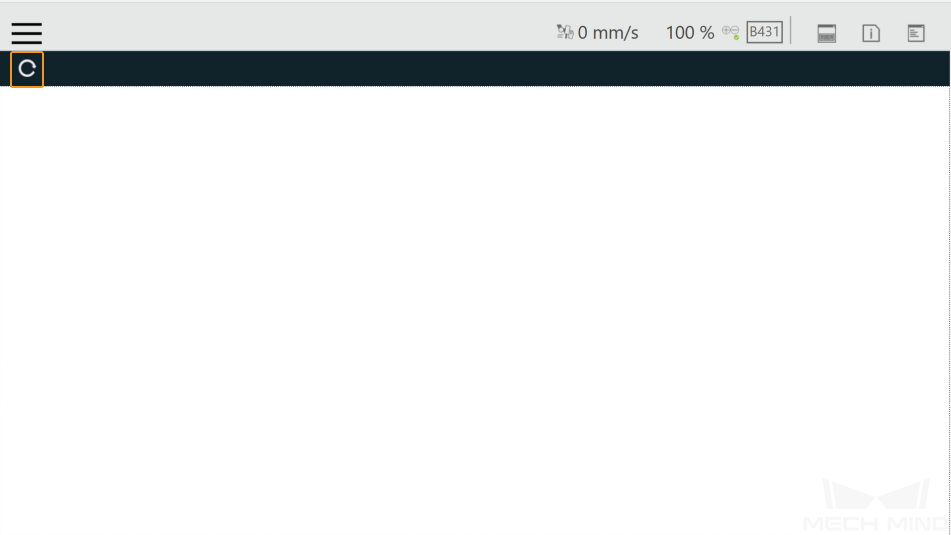

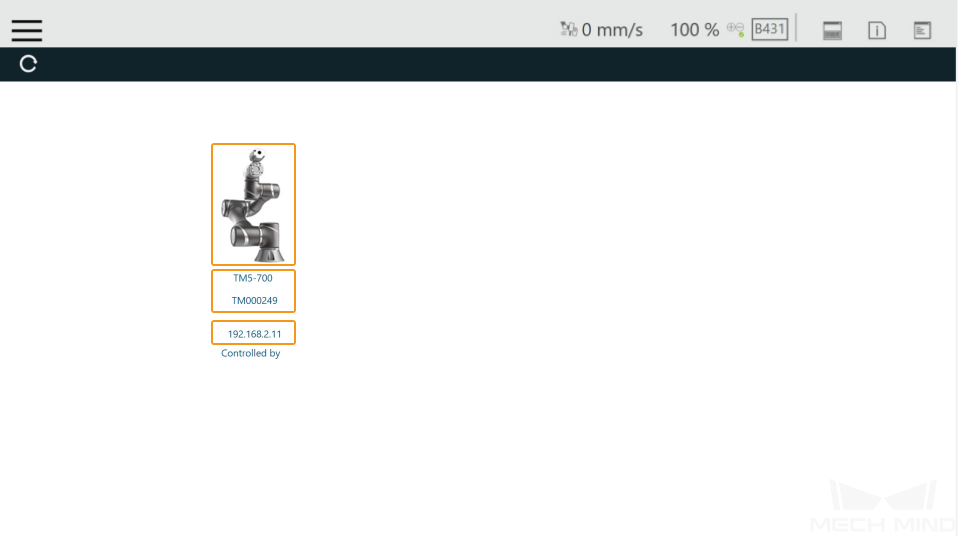

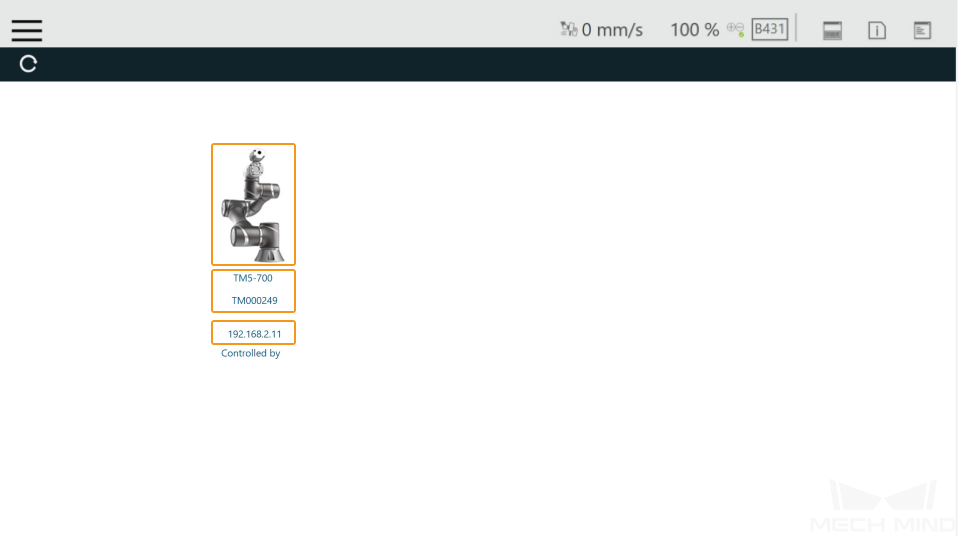

, and wait for the corresponding robot ID to appear in the window.

, and wait for the corresponding robot ID to appear in the window.

Connect the robot in any of the following ways:

Double-click the robot icon.

Double-click the robot ID.

Double-click the IP address of the robot.

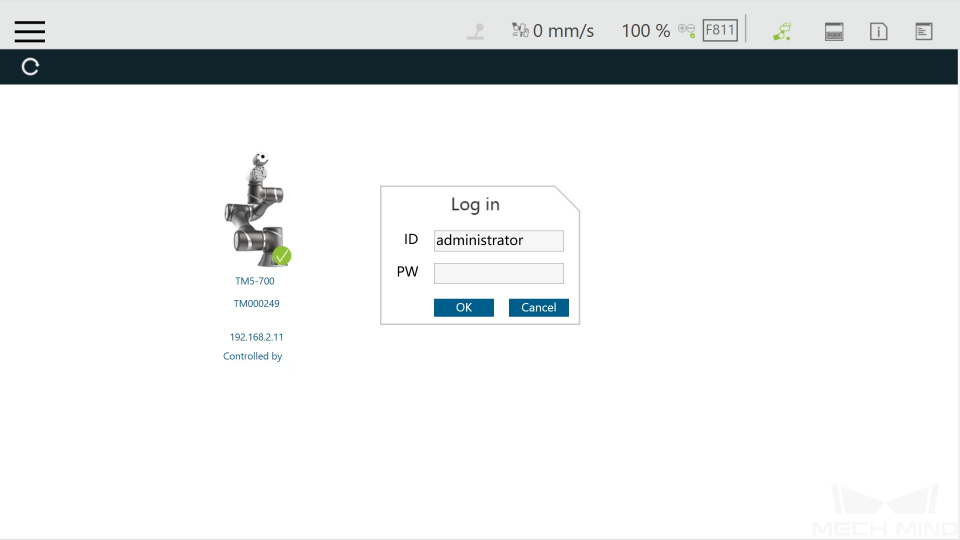

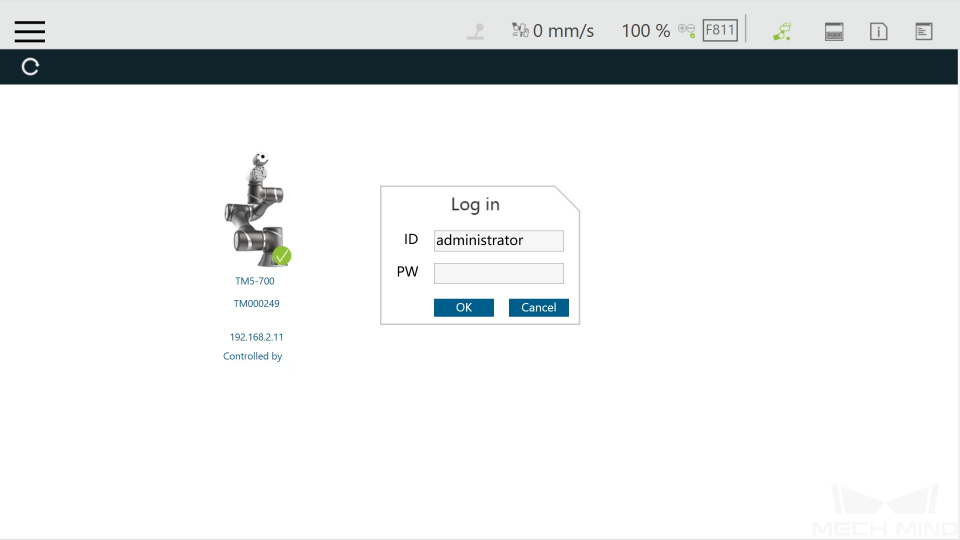

Enter your ID and password in the Log in window, and click OK. You can use the default ID administrator to log in without a password.

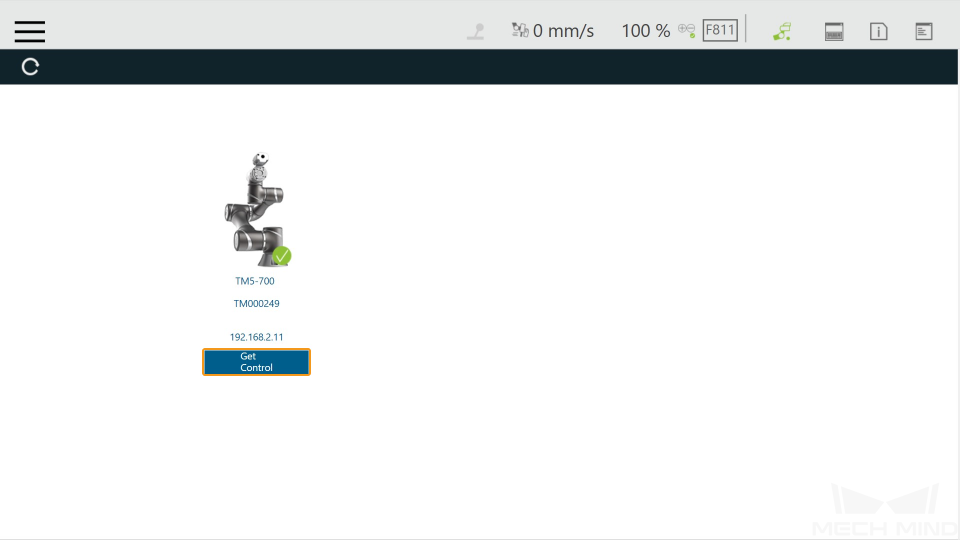

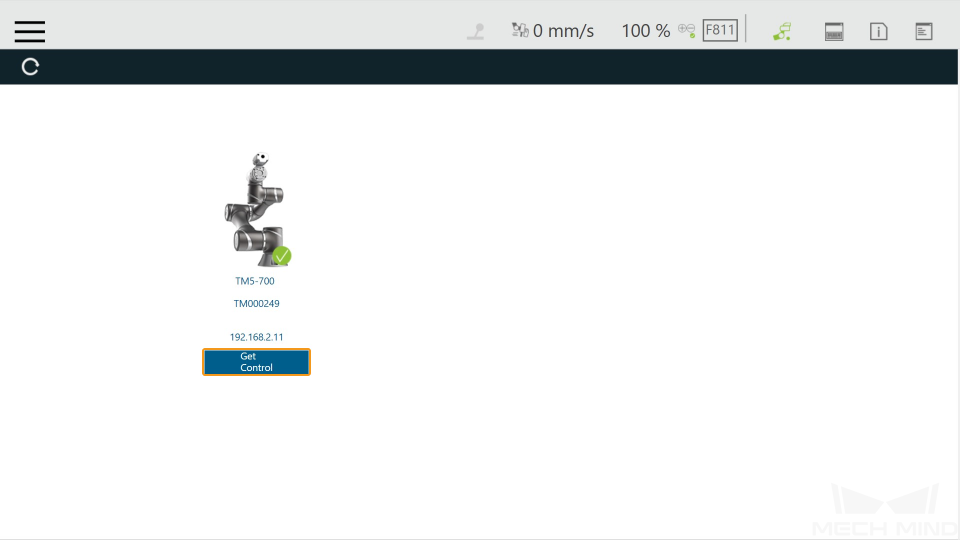

Click Get Control to control the robot.

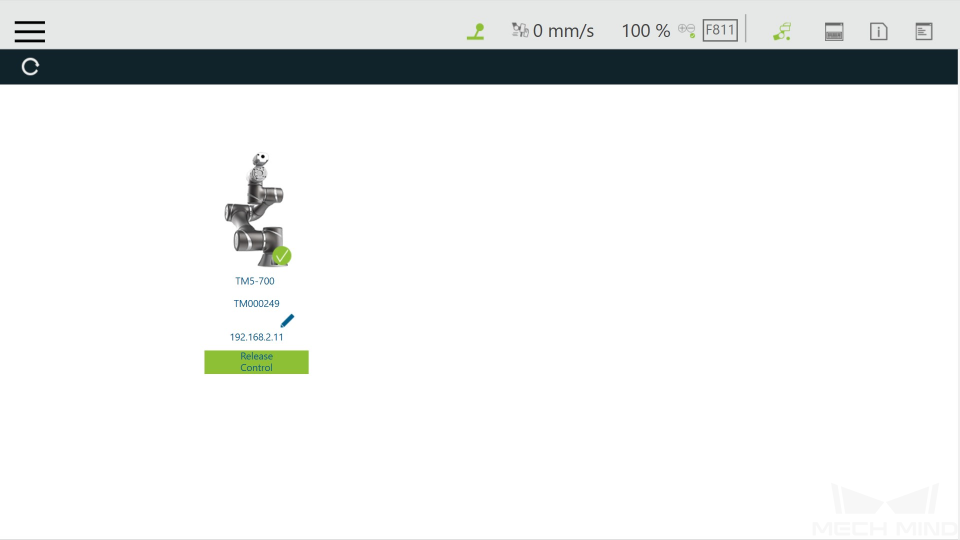

If the robot is controlled successfully, the window will be shown as below.

Control the Robot via the IPC¶

Connect Hardware¶

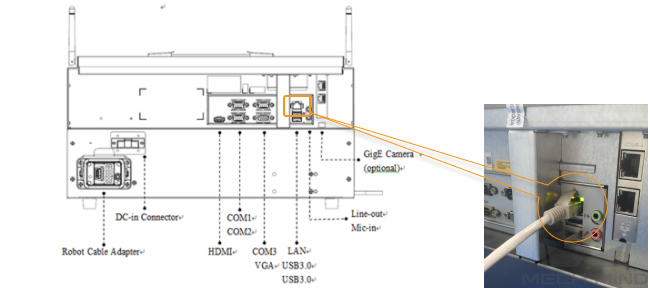

Plug the Ethernet cable into the LAN port of the robot controller to connect it with the IPC.

Set the IP Address of the IPC¶

Attention

Set the IP addresses of the IPC and robot to be in the same subnet, or else the robot cannot be connected successfully.

Control the Robot with the IPC¶

Download and install the TMflow software on your IPC from Techman Robot’s website.

Open TMflow, click

, and wait for the corresponding robot ID to appear in the window.

, and wait for the corresponding robot ID to appear in the window.

Connect the robot in any of the following ways:

Double-click the robot icon.

Double-click the robot ID.

Double-click the IP address of the robot.

Enter your ID and password in the Log in window, and click OK. You can use the default ID administrator to log in without a password.

Click Get Control to control the robot.

If the robot is controlled successfully, the window will be shown as below.

Load the Program Files¶

The example below uses an IPC to load the program files, and the method to load the program files with a controller is similar.

Prepare the Files¶

Plug the USB flash drive into the USB port of the IPC.

Rename the USB flash drive to TMROBOT, or else the USB flash drive cannot be recognized by the robot controller.

Copy the program files to the USB flash drive. The files are stored in the xxx\Mech-Mind Software Suite-x.x.x\Mech-Center\Robot_Server\Robot_FullControl\tm folder.

Attention

Please copy the entire TM_Export folder to your USB flash drive.

Plug the USB flash drive with the program files into the USB port of the robot controller.

Back up Robot System Files¶

Hint

It is recommended to back up robot system files before loading master-control program files to avoid system corruption that may be caused by the loading operation. In case any issue occurs, you can use the backup file to restore the robot system.

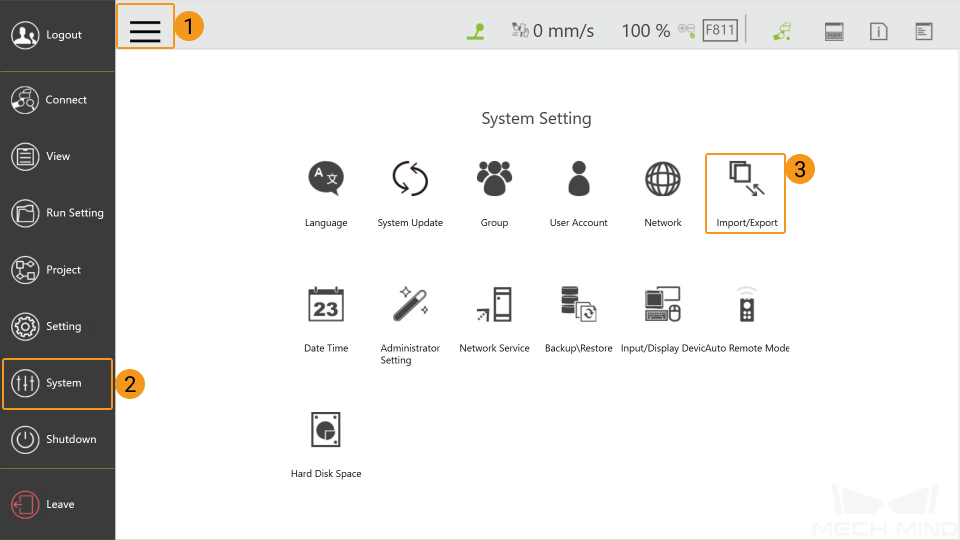

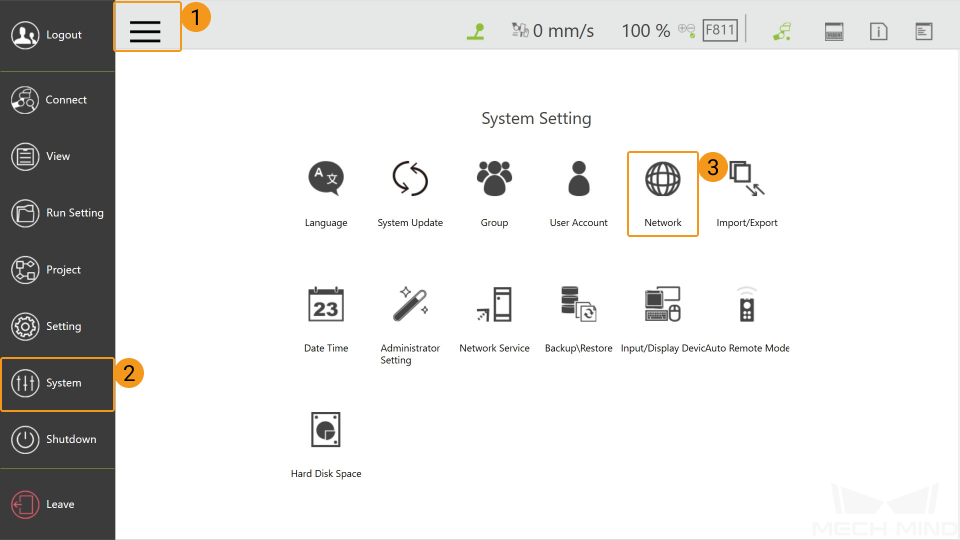

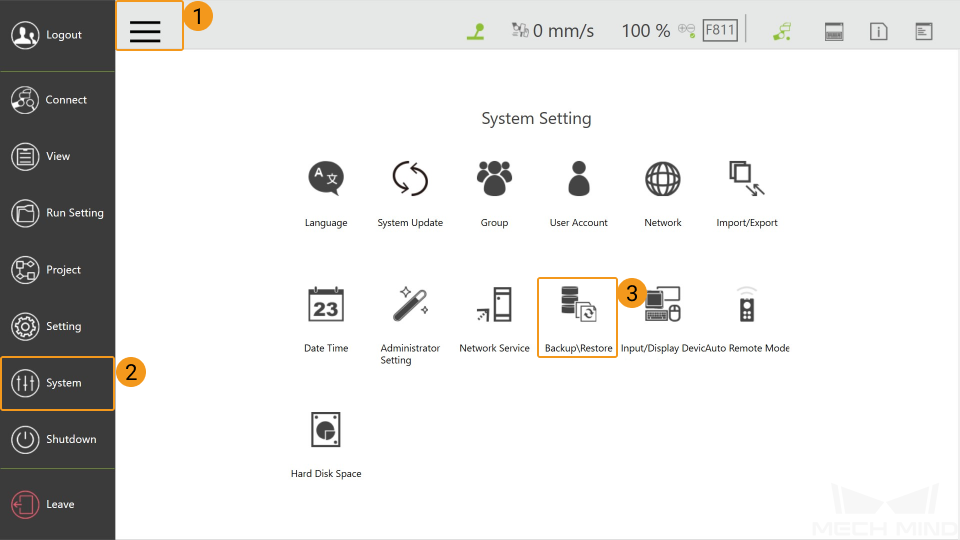

Open the TMflow software, click the

icon in the upper left corner of the window, and select .

icon in the upper left corner of the window, and select .

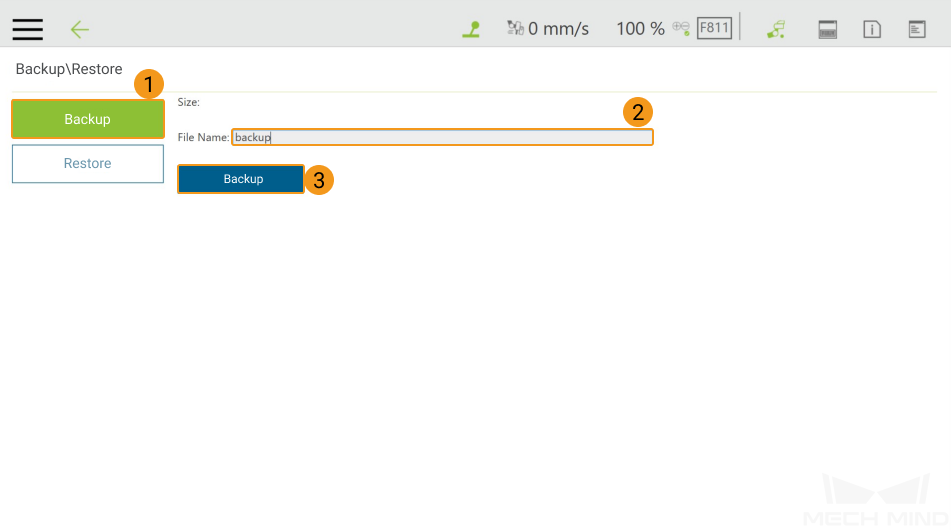

Click Backup, enter a File Name for the backup file, and then click Backup.

If you need to restore the robot system with the backup file, click Restore and then Restore.

Load the Files to the Robot¶

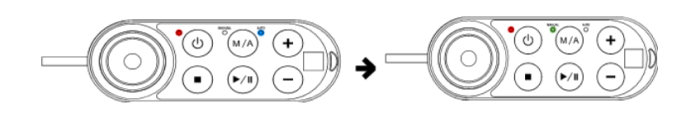

Before loading the files to the robot, please press and hold the M/A button on the Robot Stick to switch the robot to the Manual mode (the green Manual light is on).

Open the TMflow software, click

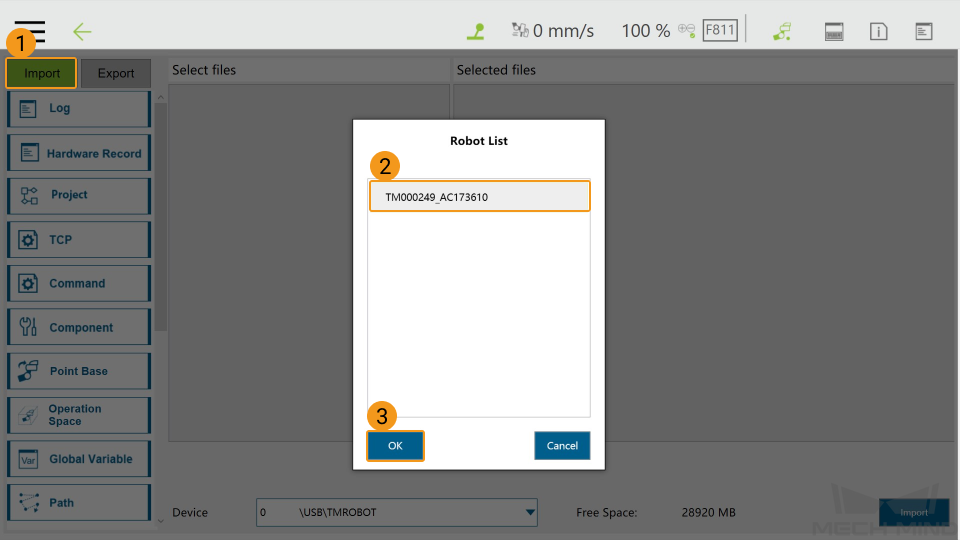

and then select .

and then select .Click Import, and a Robot List window will pop up, select the program file TM000249_AC173610 and click OK.

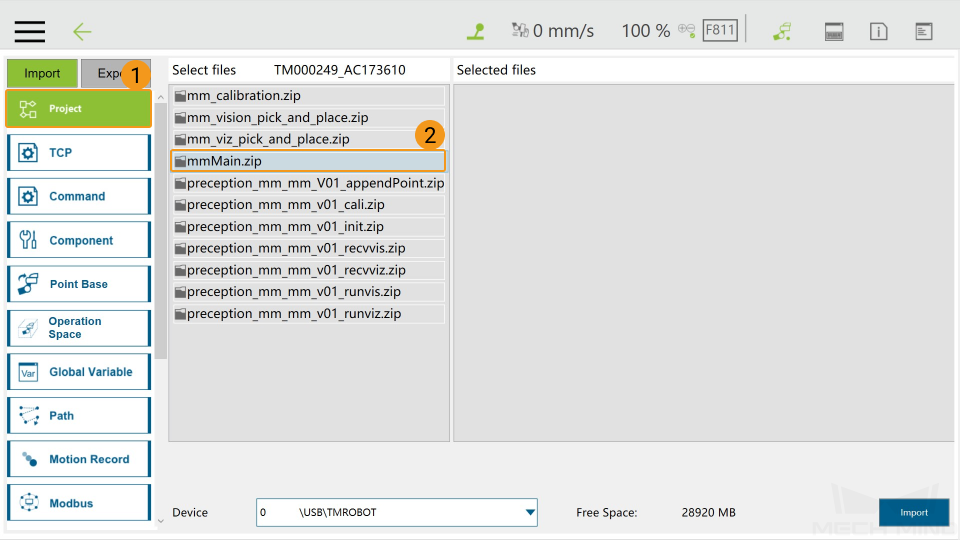

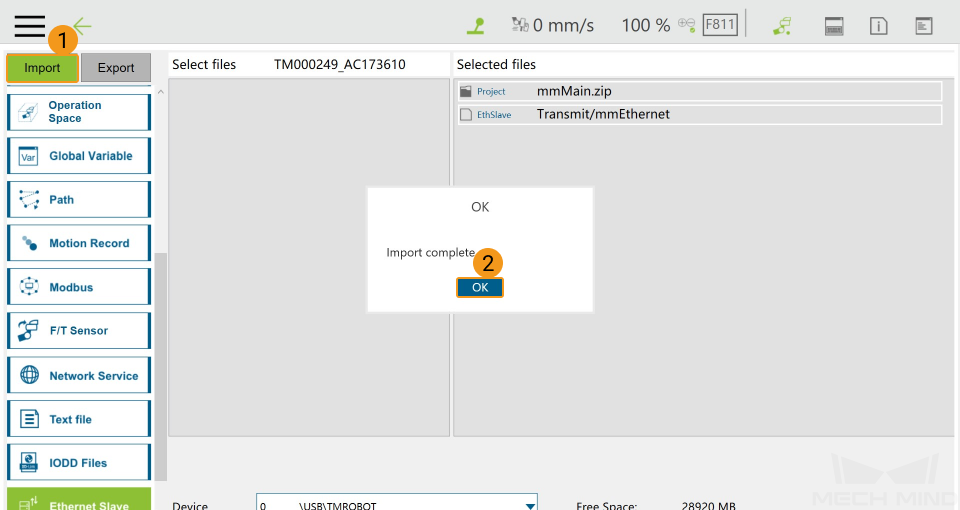

Click Project, and select mmMain.zip in the Select files, and then it will be displayed in the Selected files panel on the right.

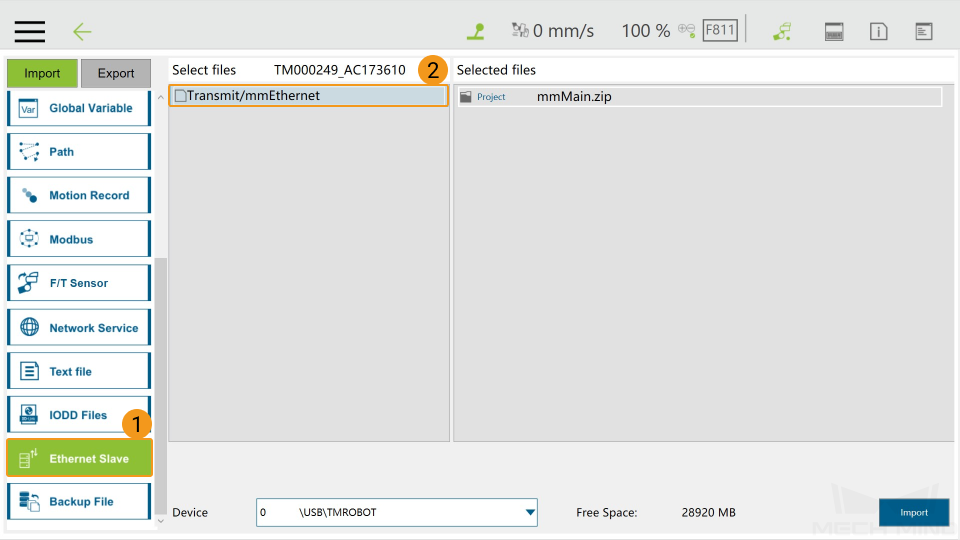

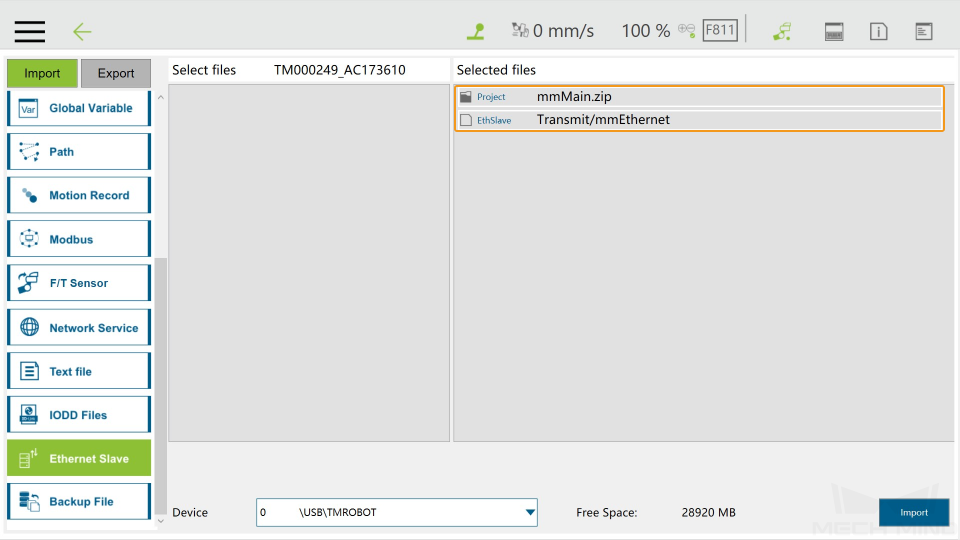

Click Ethernet Slave, and select Transmit/mmEthernet, and then it will be displayed in the Selected files panel on the right.

Click Import. After the files have been imported successfully, click OK in the Import complete pop-up window.

Unplug the USB flash drive from the IPC after you have completed the above steps.

Run the Program¶

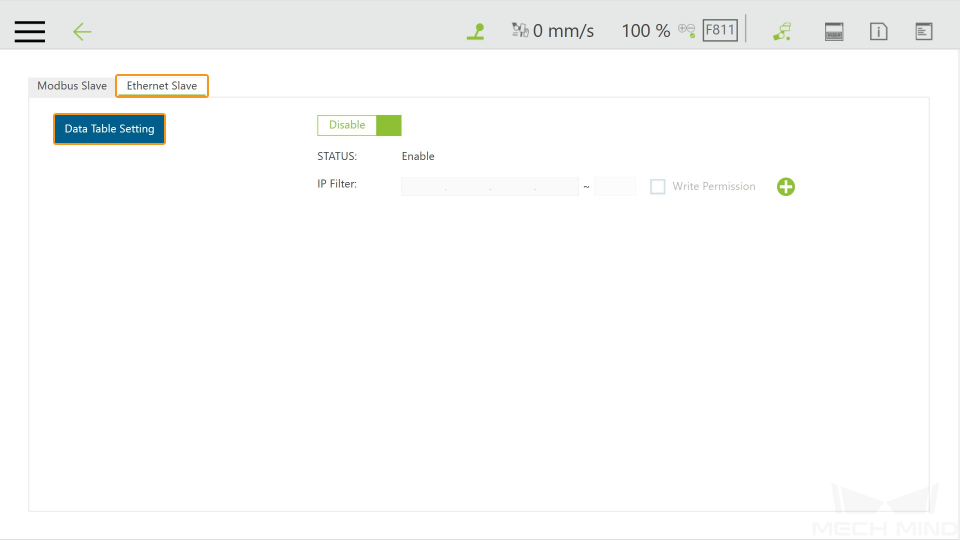

Enable the Ethernet Slave Service¶

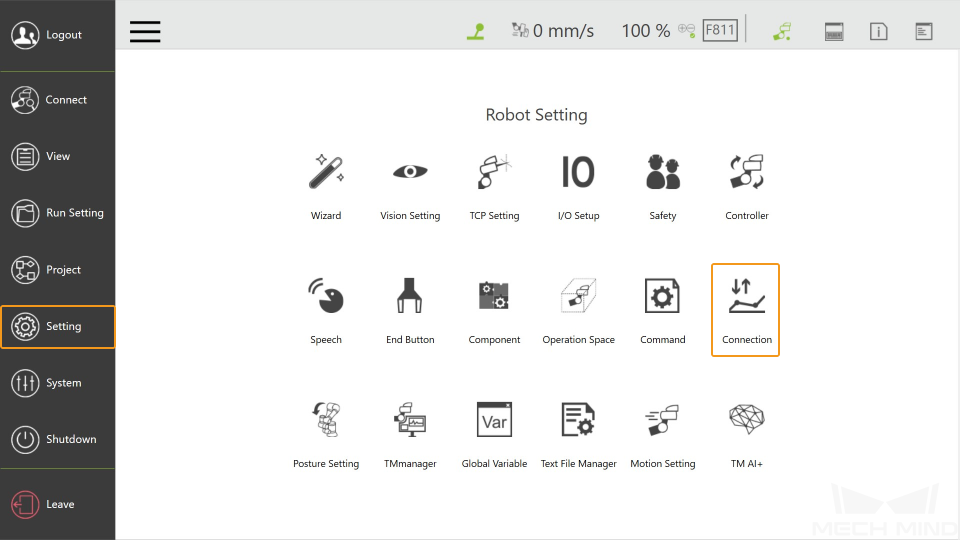

Select .

Select .

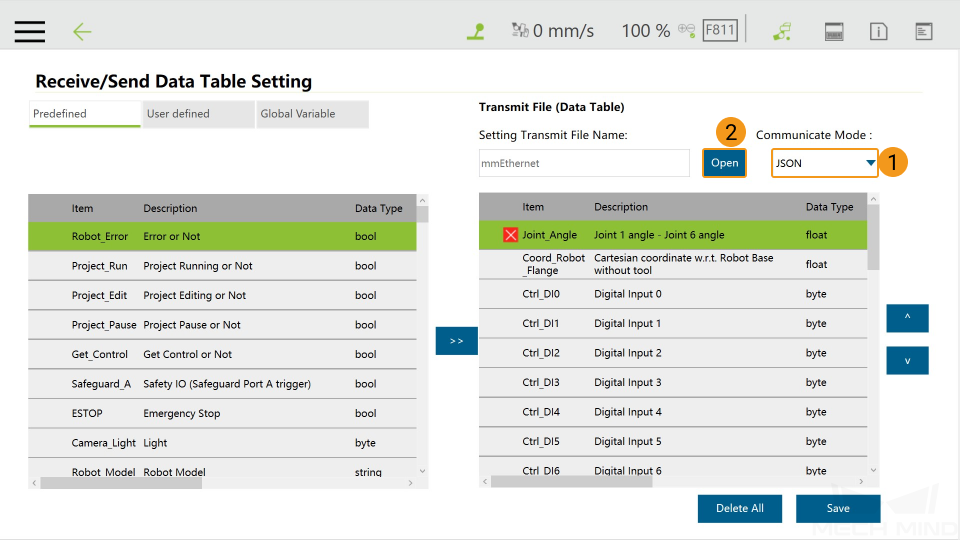

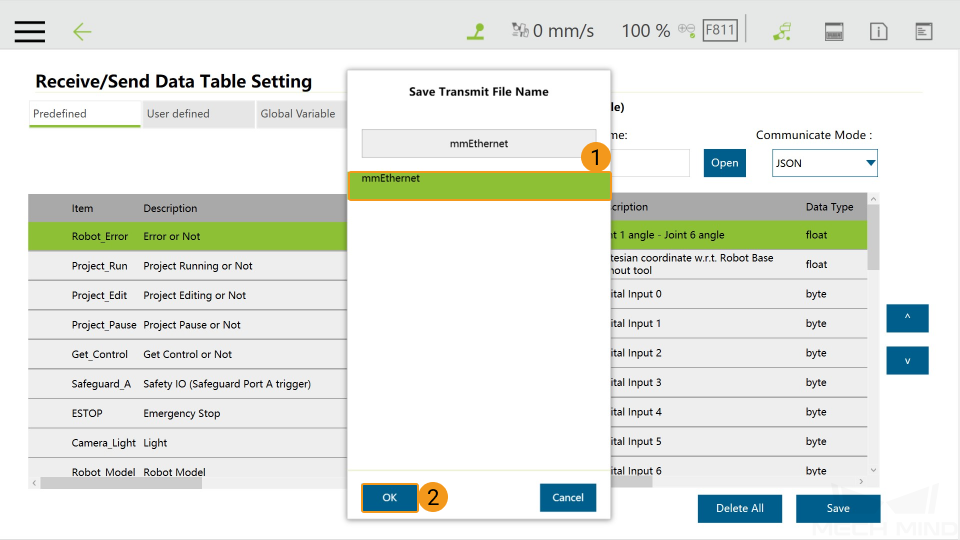

Set the Communicate Mode to JSON, and click Open.

Select mmEthernet in the pop-up Save Transmit File Name window, and click OK.

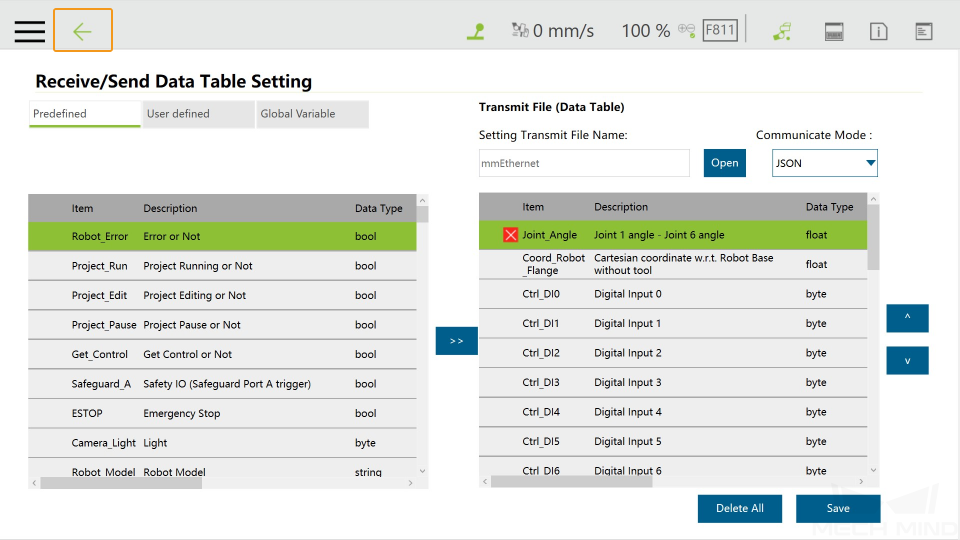

Click ← in the Receive/Send Data Table Setting window.

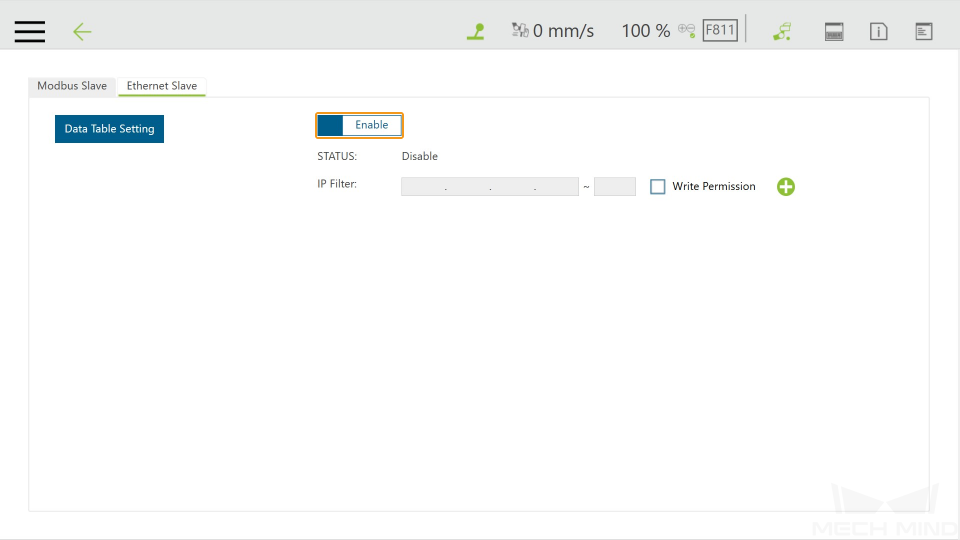

Click Enable.

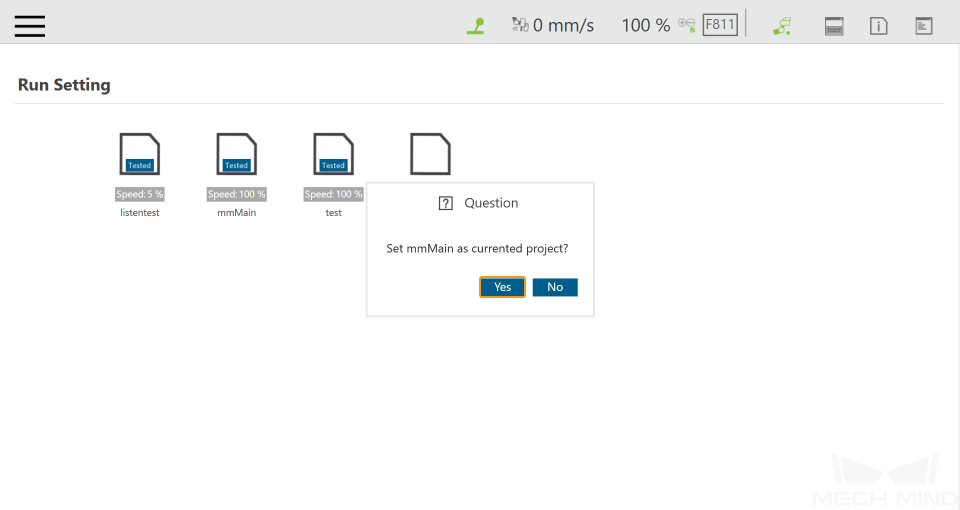

Run the mmMain Program¶

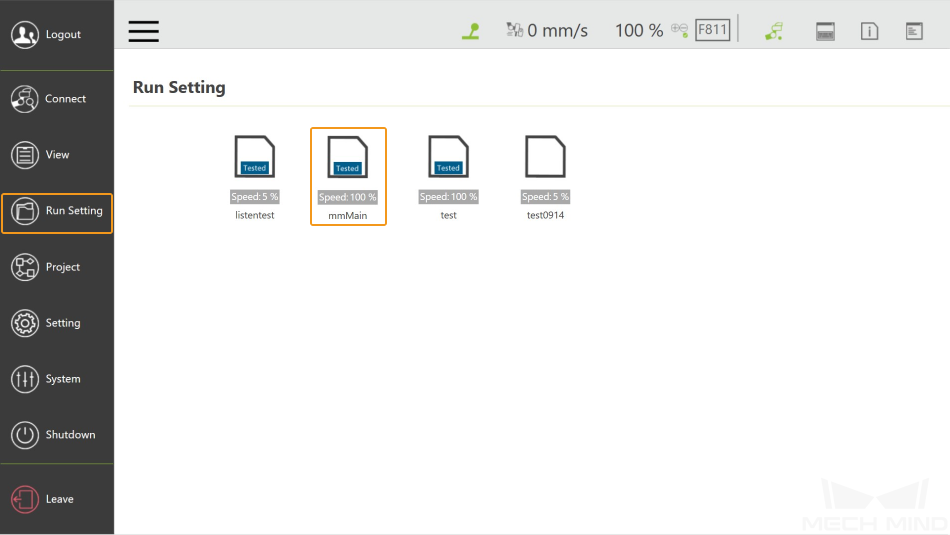

Select .

Click Yes in the pop-up window to set mmMain as the current project.

Press the M/A button on the Robot Stick until you hear a beep, which suggests that the Manual mode has been disabled.

Press the buttons + - + + - in sequence, and the blue Auto light will be on, suggesting that the robot has been switched to the Auto mode.

Then press the Run button on the Robot Stick, and the program will be run after three beeps.

Test Robot Connection¶

Configure Robot in Mech-Viz¶

Open Mech-Viz, click New project to create a new project.

Select the robot model in use in the next page.

Save the project by pressing Ctrl + S.

In the toolbar, change the Vel. (velocity) and Acc. (acceleration) parameters to 5%.

Right-click the project name in Resources and select Autoload Project.

Configure Settings in Mech-Center¶

Open Mech-Center and click on Deployment Settings.

Go to Robot Server, and make sure Use robot server is checked.

Check if the robot model displayed next to Robot type in Mech-Viz project matches the one in use.

Set the Robot IP address, and click Save.

Connect to Robot in Mech-Center¶

Click Connect Robot on the toolbar.

The robot is successfully connected if:

A message saying Robot: server connected to the robot shows up in the Log panel, and

A robot icon with the robot model shows up in the Service Status panel.

Move the Robot¶

In Mech-Viz, click Sync Robot on the toolbar to synchronize the pose of the real robot to the simulated robot. Then, click Sync Robot again to disable the synchronization.

Click the Robot tab in the lower right, and change the joint position of J1 slightly (for example, from 0° to 3°). The simulated robot will move accordingly.

Click Move real robot, the real robot should move accordingly.

Attention

When moving the robot, please pay attention to safety hazards. In the case of an emergency, press the emergency stop button on the teach pendant!

Note

After running the mmMain program on the robot side but Mech-Center fails to connect the robot, you can use NetAssist in the xxx\Mech-Mind Software Suite-x.x.x\Mech-Center\tool directory as a client to connect the 5890 and 5891 ports of the robot to check if these two ports are opened successfully.

If port 5890 cannot be connected successfully, please check whether the mmMain program on the robot side has been run successfully.

If port 5891 cannot be connected successfully, please check whether the Ethernet Slave on the robot has been enabled or restart the robot.