AUBO Setup Instructions¶

This section introduces the process of setting up master control of an AUBO robot.

The process consists of the following steps:

Check Controller Compatibility¶

The version of the controller should be above 4.5.44.

Go to to check the version of the controller.

Set up the Network Connection¶

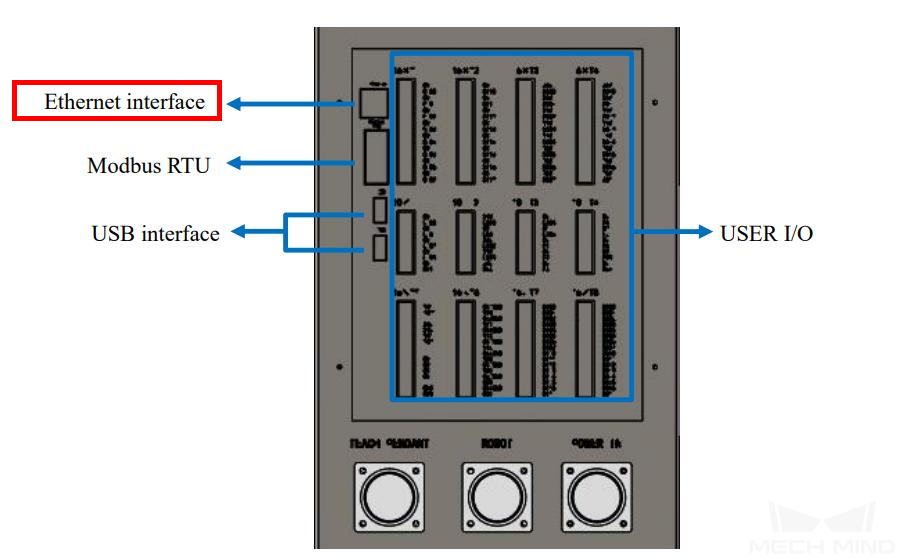

Hardware Connection¶

Plug the Ethernet cable into the Ethernet interface of the controller to connect the IPC and the robot controller.

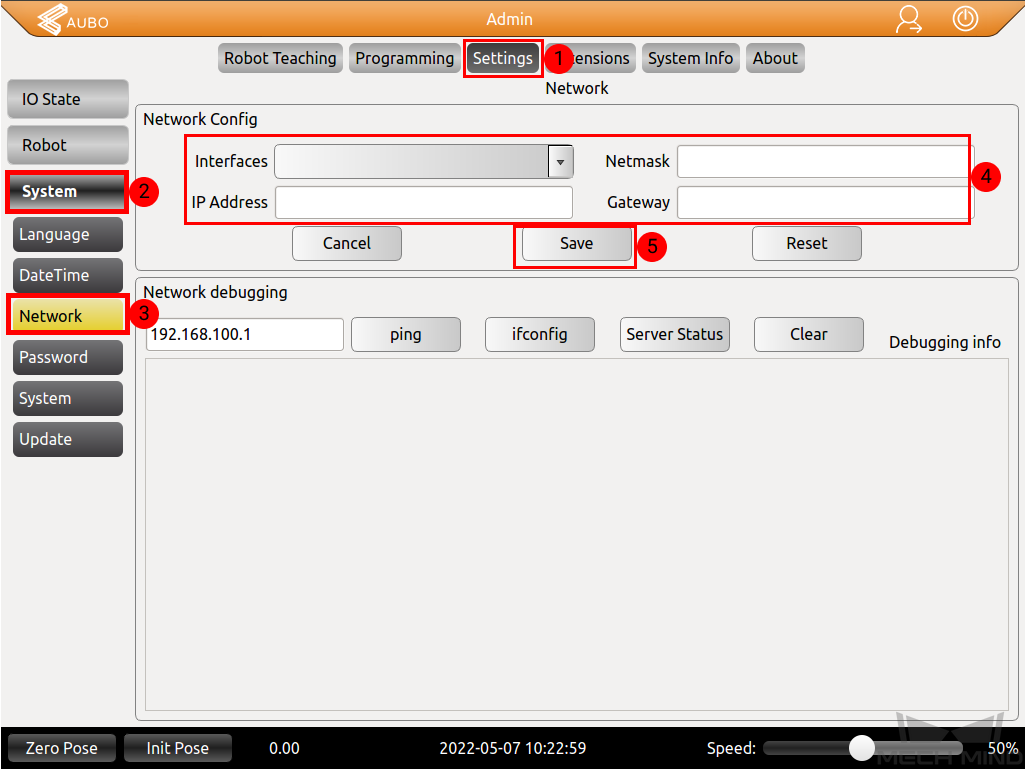

IP Configuration¶

Press on to configure the Interfaces, Netmask, IP Address, and Gateway, and then select Save. Please note that the robot IP should be in the same subnet as the IPC.

Test Robot Connection¶

Configure Robot in Mech-Viz¶

Open Mech-Viz, click New project to create a new project.

Select the robot model in use in the next page.

Save the project by pressing Ctrl + S.

In the toolbar, change the Vel. (velocity) and Acc. (acceleration) parameters to 5%.

Right-click the project name in Resources and select Autoload Project.

Configure Settings in Mech-Center¶

Open Mech-Center and click on Deployment Settings.

Go to Robot Server, and make sure Use robot server is checked.

Check if the robot model displayed next to Robot type in Mech-Viz project matches the one in use.

Set the Robot IP address, and click Save.

Connect to Robot in Mech-Center¶

Click Connect Robot on the toolbar.

The robot is successfully connected if:

A message saying Robot: server connected to the robot shows up in the Log panel, and

A robot icon with the robot model shows up in the Service Status panel.

Move the Robot¶

In Mech-Viz, click Sync Robot on the toolbar to synchronize the pose of the real robot to the simulated robot. Then, click Sync Robot again to disable the synchronization.

Click the Robot tab in the lower right, and change the joint position of J1 slightly (for example, from 0° to 3°). The simulated robot will move accordingly.

Click Move real robot, the real robot should move accordingly.

Attention

When moving the robot, please pay attention to safety hazards. In the case of an emergency, press the emergency stop button on the teach pendant!

Troubleshooting¶

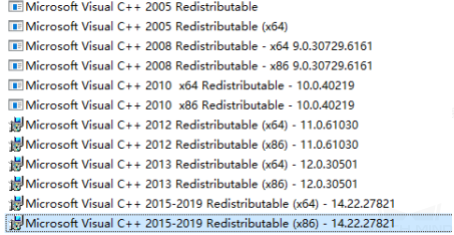

If the robot cannot be connected successfully, and the error is DLL load failed: %1 is not a valid Win32 application, please check whether the C++ runtime library on your computer is complete. The complete C++ runtime library is shown below.

If the library is not complete, please download the vc runtime library repair DirectX Repair V3.9 to fix the error.