Communication Configuration and Example Program Usage¶

This topic provides instructions on setting up the Standard Interface communication based on the Siemens PLC Snap7 protocol between a Siemens SIMATIC S7 PLC and Mech-Mind Software Suite using the TIA Portal software.

Hardware and Software Prerequisites¶

Hardware¶

The following S7 PLCs from Siemens are supported:

S7-300: Integrated PN network port or CP343-1

S7-400: Integrated PN network port or CP443-1

S7-1200: None

S7-1500: None

Power adapter: 220V AC to 24V DC

Mech-Mind Vision System IPC or host

Network cable

Software¶

Siemens PLC programming software TIA Portal V15.1.

Mech-Mind Software Suite: 1.7.0 or above.

Interface file for S7 communication between software Siemens Tia Portal and Mech-Mind Software Suite:

Data block file Mech-Mind Interface.db for data communication.

File Mech-Mind Interface Program.scl for implementing the functions of various interface commands.

Hint

The files are located in xxx\Mech-Mind Software Suite-x.x.x\Mech-Center\Robot_Interface\Siemens Snap7\TIA Portal in the installation directory of Mech-Mind Software Suite. Please copy the file to the computer where the software TIA Portal is installed.

Creation and Configuration of PLC Projects¶

Create a PLC project¶

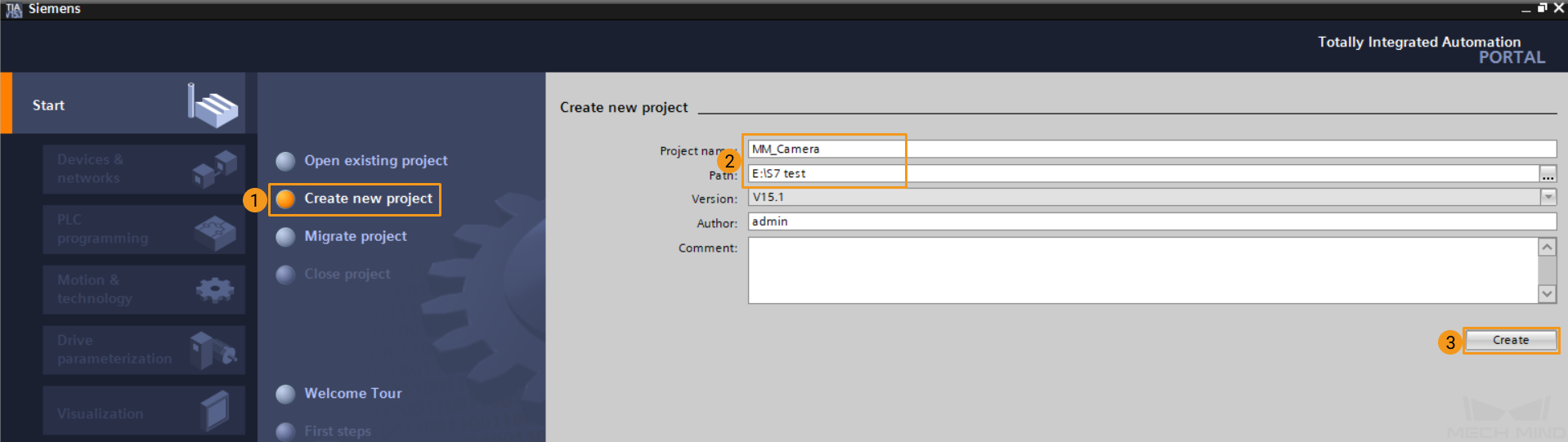

Open TIA Portal, click on Create new project, enter project name, select a path, and click on Create. A new window will pop up. Click on Open project view.

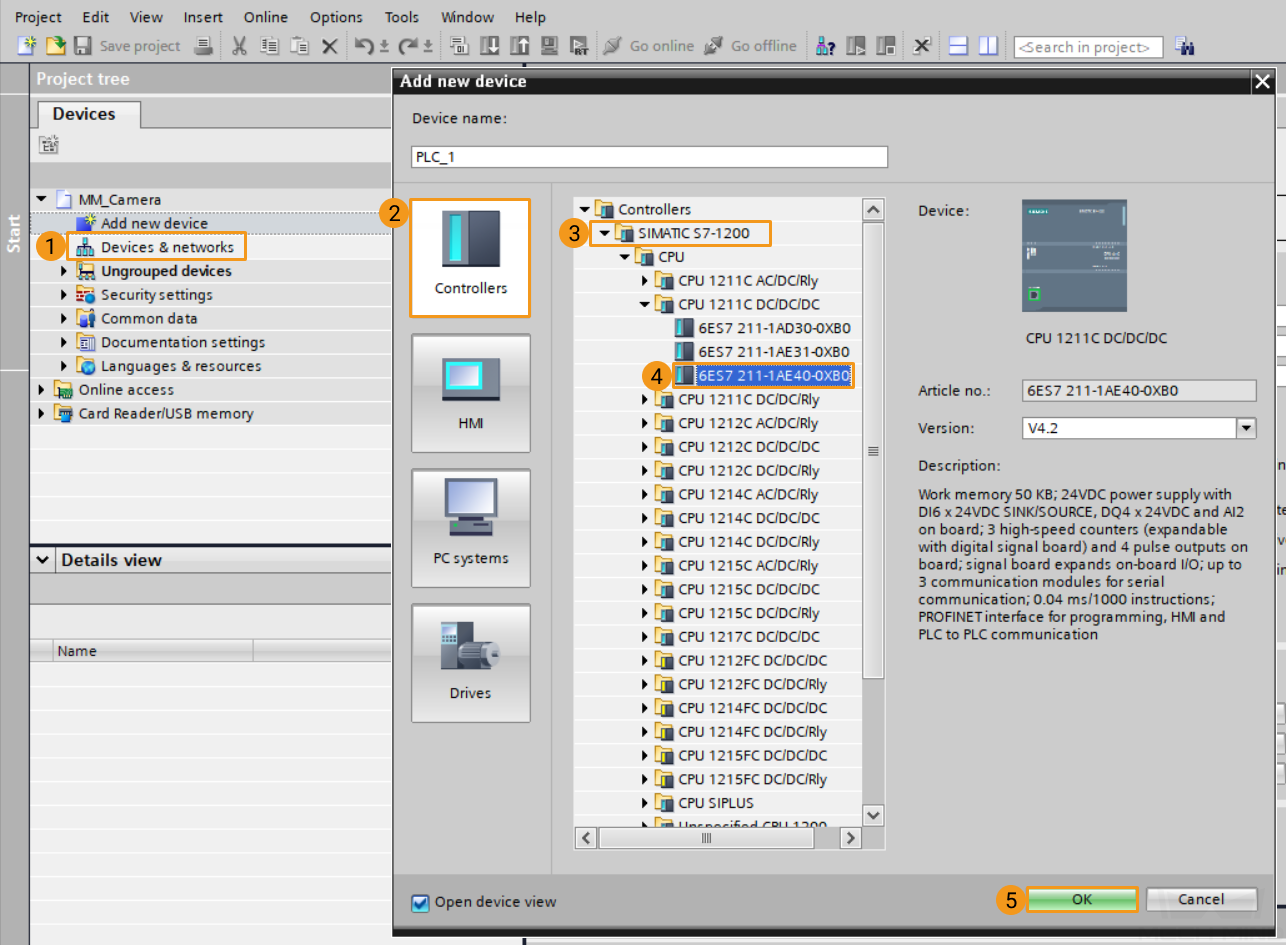

In the Project tree section, double-click on Add new device to open the window. Under Controllers, select the module that is consistent with the physical PLC. The default device name can be used. Click on OK.

On the device configuration page, click on Device view, then double-click the network port label of PLC_1. On the Properties/General page, click Ethernet address and set the IP address to 192.168.1.22. The default subnet mask can be used (should be in the same network segment as the vision system’s IPC).

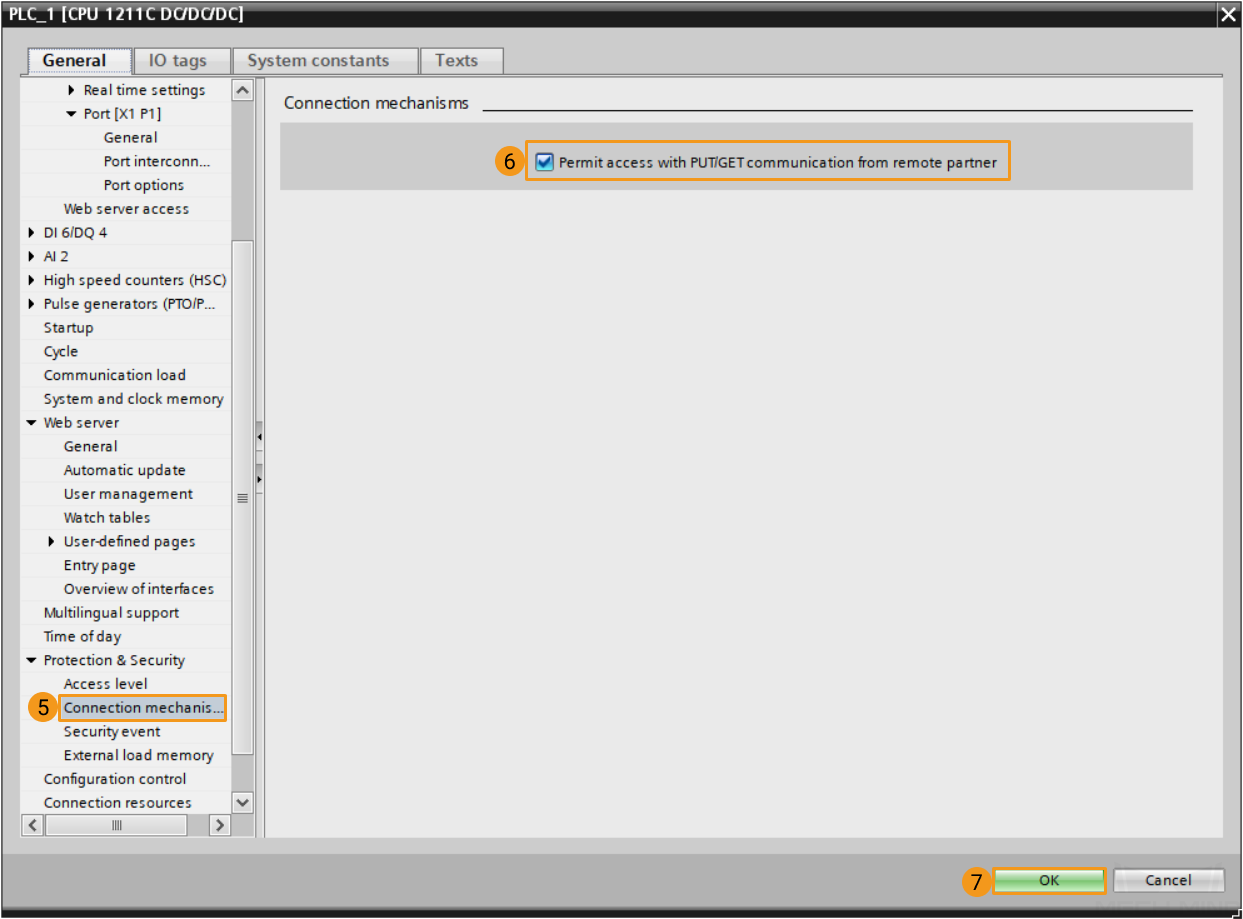

#. Select the device PLC_1 in the project tree, right-click and select Properties, and enter the interface in turn in the pop-up window. Under Access level, check Full access (no protection). Under Connection mechanisms, check Permit access with PUT/GET communication from remote partner. Click on OK to save the project.

Import the S7 Communication Interface File¶

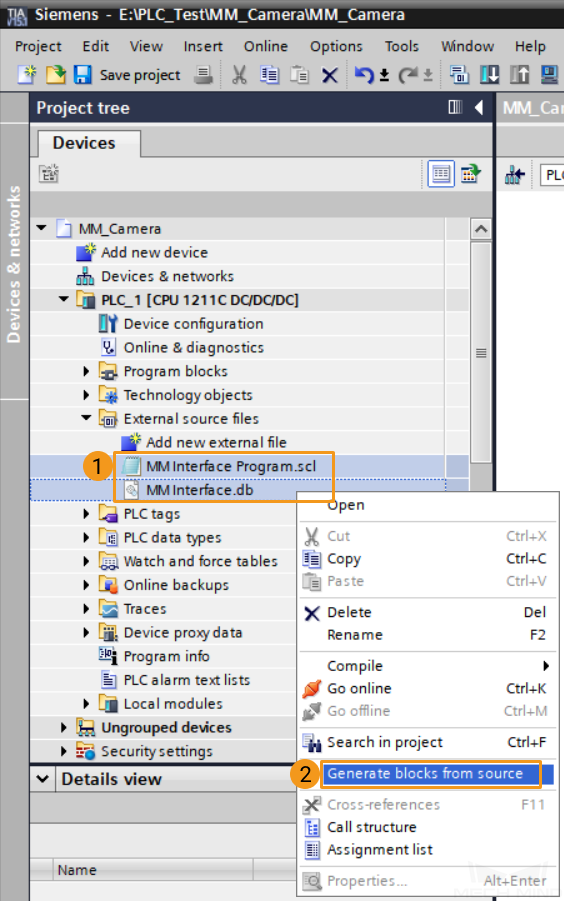

Under the project tree, click on External source files and Add new external file. In the pop-up window, select files Mech-Mind Interface.db, Mech-Mind Interface Program.scl, and click on Open to import the files to the new project.

Select the newly imported external source files (select Mech-Mind Interface.db first, then select Mech-Mind Interface Program.scl ), right-click, and select Generate blocks from source. Click on OK in the pop-up window (this operation will overwrite the functions and data blocks with the same names in the project, and automatically select an unoccupied number).

Hint

If the operations are not performed in the order of the selected files above, an error message will appear in the log window.

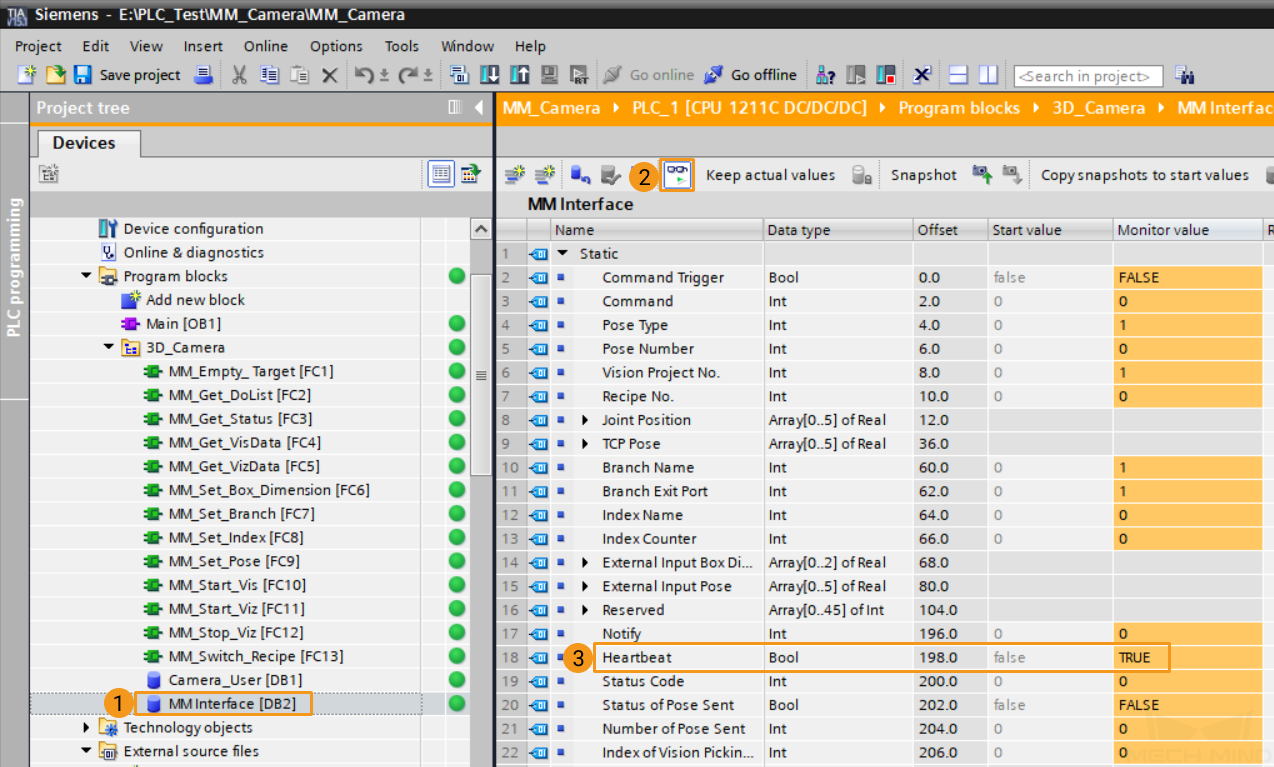

The functions and data blocks generated by the external source file are as follows, where the DB number of Mech-Mind Interface must be consistent with the DB number set in Robot and Interface Configuration in Mech-Vision. The DB Camera_User is used to store user data.

In the project, to facilitate the maintenance of Mech-Mind functions and data blocks, you can right-click the program block, select Add new group, name it Mech-Mind, and select all the newly generated function functions and data blocks and move them to the group folder.

Download the S7 Communication Interface File¶

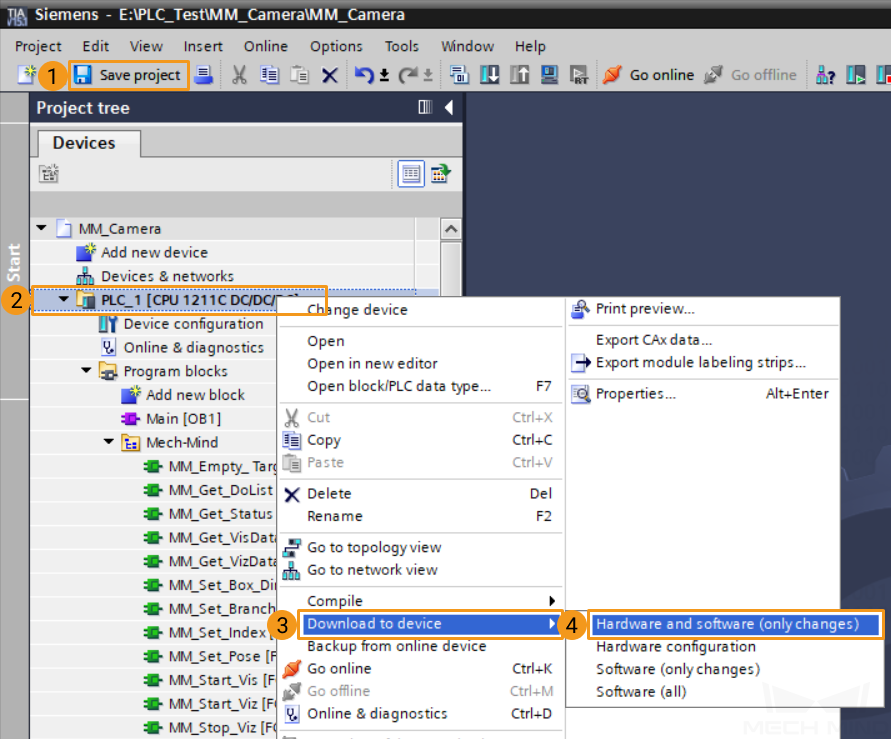

Click on Save project , then in the project tree, right-click on the new project PLC_1. Select in turn, and the download window will pop up.

In the download window that pops up, select the network card driver connected to PLC for PG/PC interface, select Direct at slot ‘1 X1’ for Connection to interface/subnet, select Show all compatible devices for Select target device, and then click on Start search. Select the detected CPU device, click Download, click Finish after the download is complete.

Configure and Start Communication¶

Set the IP address of the IPC and the IP address of the PLC to the same subnet. Open the cmd command prompt of the IPC (by searching for cmd), enter ping xxx.xxx.xxx.xxx (the IP address of the PLC), and test whether the connection between the industrial computer and the PLC is normal.

Set up “Robot and Interface Configuration” in Mech-Vision¶

Click Robot and Interface Configuration on the toolbar of Mech-Vision.

Select Listed robot from the Select robot drop-down menu, and then click Select robot model.

Select the robot model that you use, and then click Next.

Select the following options and click Apply.

Interface Type: Standard Interface

Protocol: Siemens PLC Client

PLC IP address: according to the setting in SIMATIC Manager

Slot number: 1

DB number: 2

Make sure the Interface Service is started: on the toolbar of Mech-Vision, the Interface Service switch on the far right is flipped and turned to blue.

The PLC is successfully connected if the following message is displayed in the Console tab of Mech-Vision Log panel:

Connect to PLC server successfully

If not, please check the configuration and check whether the physical connection is normal.

Test with Mech-Vision/Mech-Viz Project¶

This section describes how to use the Mech-Mind-Siemens TIA S7 interface program for the startup and data acquisition of Mech-Vision and Mech-Viz projects. For the specific functions and introduction of S7 communication parameters, please see Siemens PLC.

Prerequisites¶

Mech-Vision project(s):

Executable

Set to autoload: right-click the solution and select Autoload Solution. Projects in the solution are also autoloaded.

Mech-Viz project:

Executable

Set to autoload: right-click the project name in Resources and select Autoload Project

Contains a “Branch by Msg” Step that has been renamed to 1.

Get Vision Points from Mech-Vision¶

Parameter Settings¶

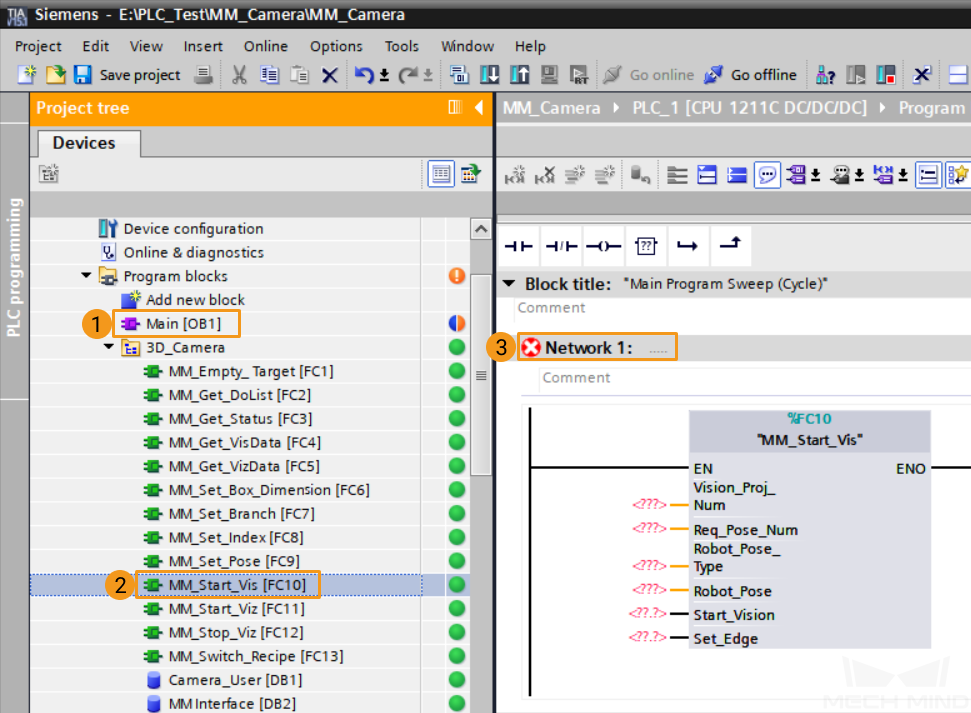

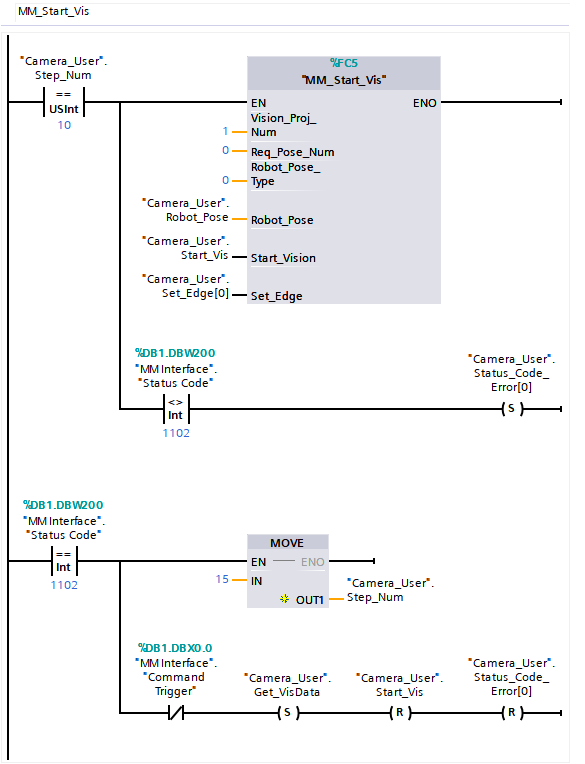

In the main interface of TIA Portal, under the project tree, double click Main [OB1] under Program blocks, and drag the function MM_Start_Vis to Network 1 of the main program.

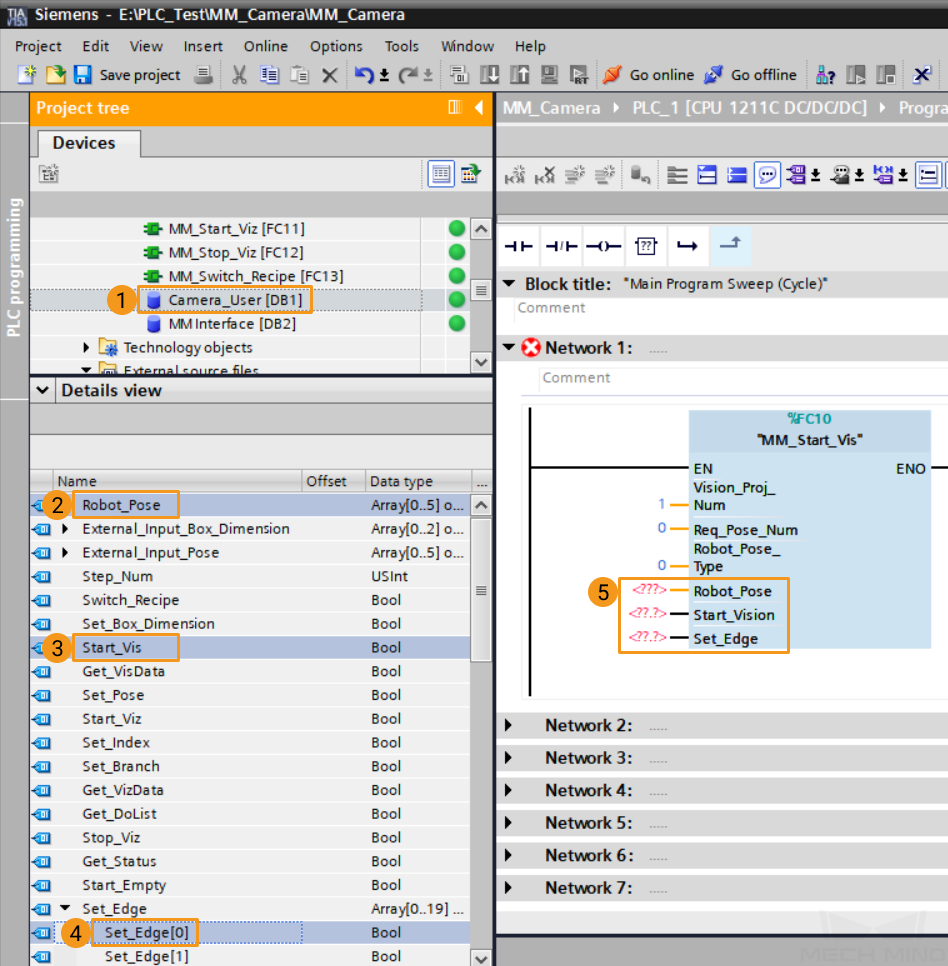

Set Mech-Vision project ID: change the value of the Vision_Proj_Num port to the ID of the Mech-Vision project you wish to run. For example, if the value is changed to 1, then project No. 1 in Mech-Vision will be started.

Set the number of poses expected in the vision result from the Mech-Vision project. In this example, set the port value of Req_Pose_Num, indicating expecting that all the poses in the vision result should be returned from Mech-Vision.

Set the type of pose expected from the robot. In this example, set the port value of Robot_Pose_Type to 0, indicating no image-capturing pose needs to be read from the robot (such as in the eye-to-hand mode).

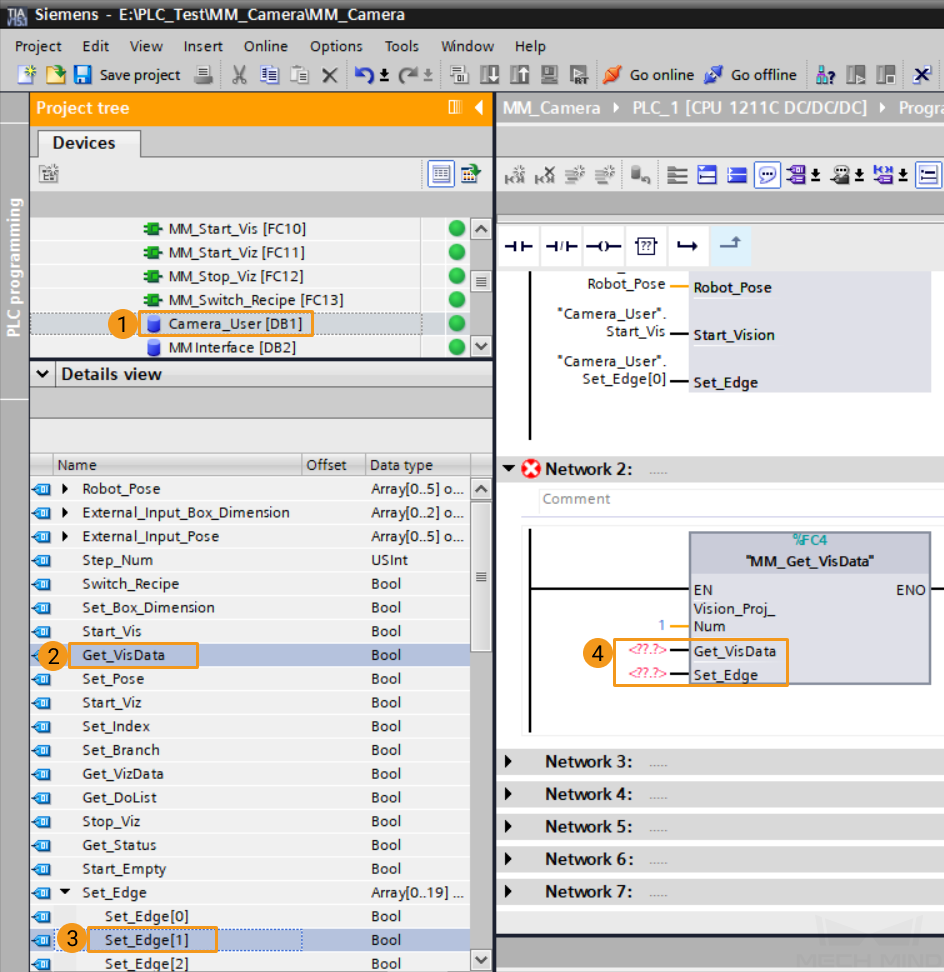

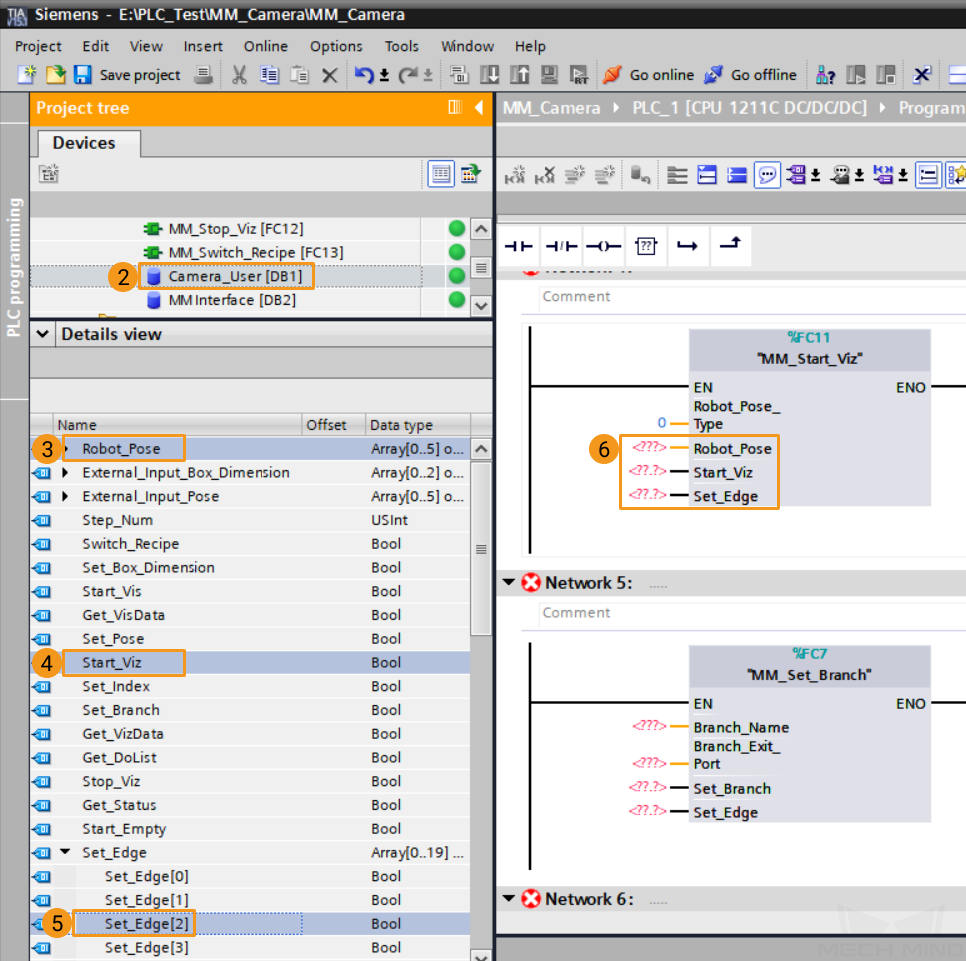

Under the project tree, click on the data block Camera_User, and drag the parameters under Details view to the corresponding ports of MM_Start_Vis.

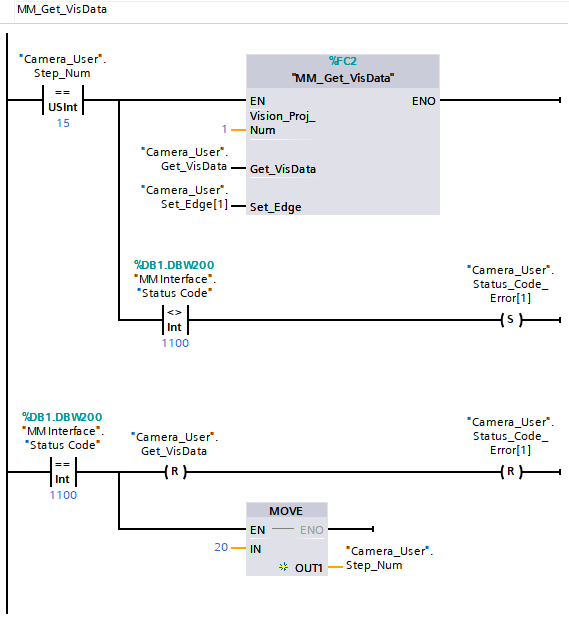

Drag the MM_Get_VisData function to Network 2 of the main program.

Set Mech-Vision project ID: change the value of the Vision_Proj_Num port to the ID of the Mech-Vision project you wish to run. For example, if the value is changed to 1, then project No. 1 in Mech-Vision will be started.

Under the project tree, click data block Camera_User, and drag the parameters under Details view to the corresponding ports of MM_Get_VisData.

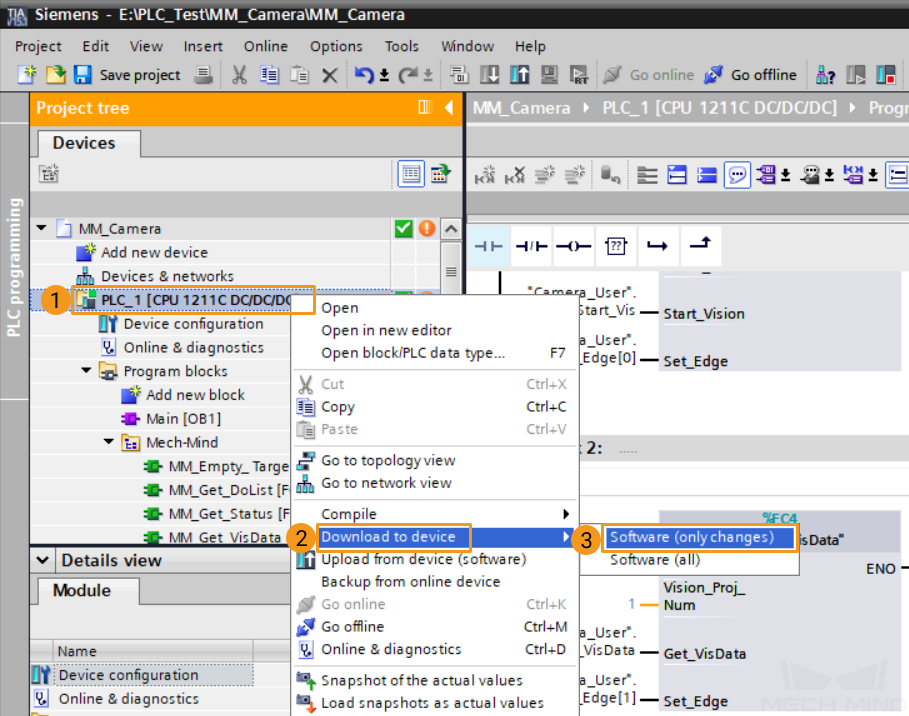

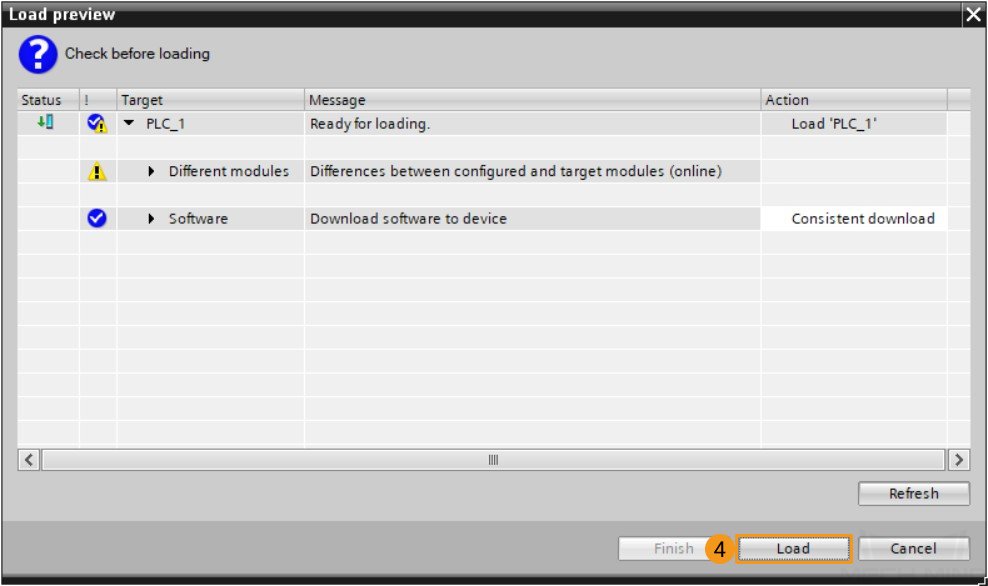

Under the project tree, click to select PLC_1, select . Click Load in the pop-up download window to download the latest program to the PLC.

Trigger the Running of the Mech-Vision Project¶

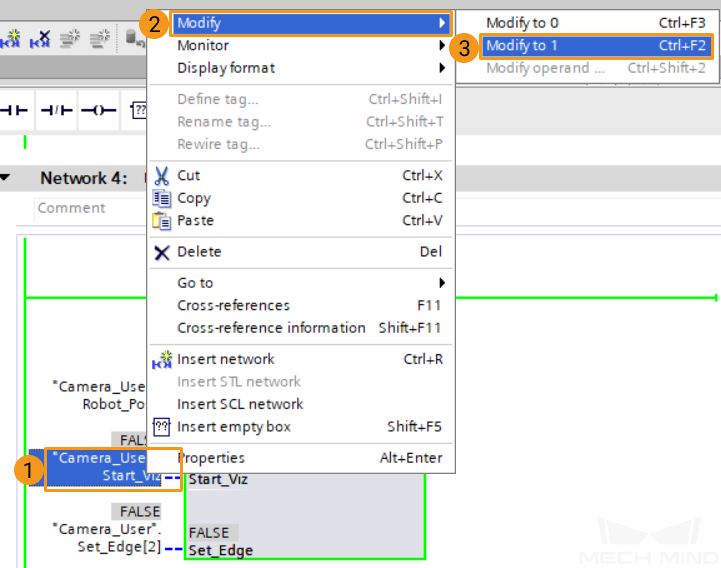

In the main program window of Main [OB1], click Enable/Disable Monitoring

to enable monitoring.

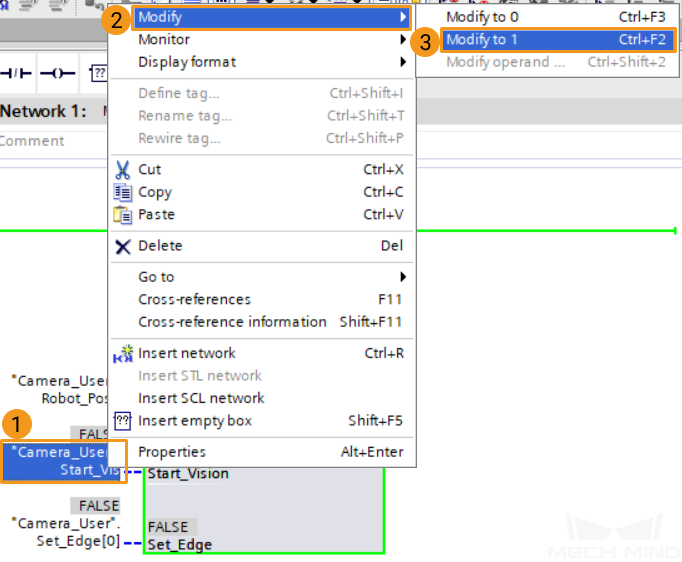

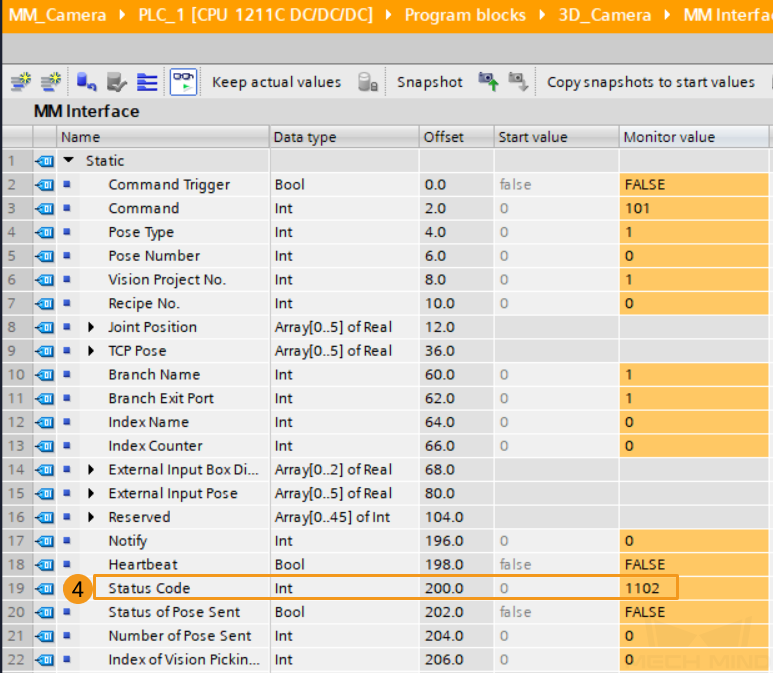

to enable monitoring.Right-click on the input-side parameter “Camera_User”.Start_Vis of MM_Start_Vis and change its value to 1 to trigger the running of the Mech-Vision project, and then reset this parameter. At this time, the parameter StatusCode of Mech-Mind Interface should have a returned value of 1102. Otherwise, an error has occurred, and please see Status Codes and Troubleshooting for further instructions.

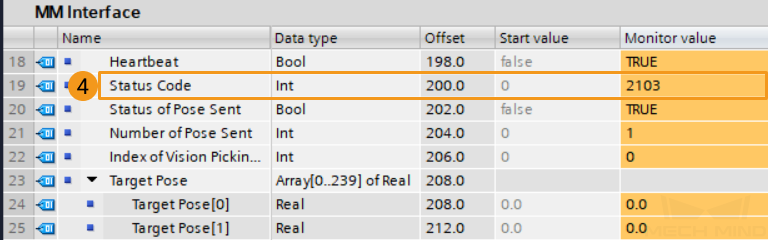

Get Vision Target(s) Calculated by Mech-Vision¶

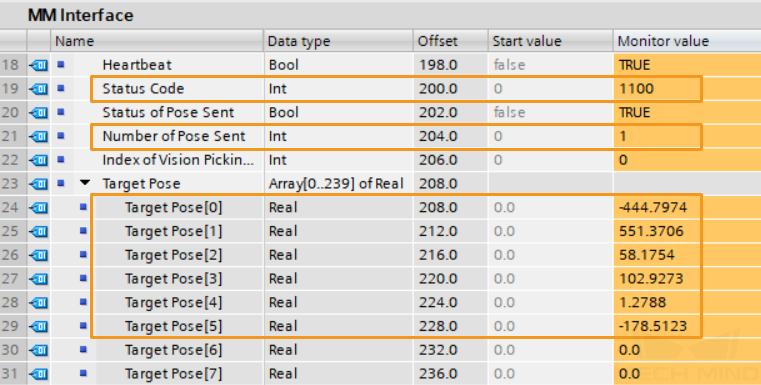

Right-click on the input-side parameter “Camera_User”.Start_Vis of MM_Get_VisData and change its value to 1 to obtain the vision result, and reset its value. At this time, the parameter StatusCode of Mech-Mind Interface should have a returned value of 1100. Otherwise, an error has occurred, and please see Status Codes and Troubleshooting for further instructions.

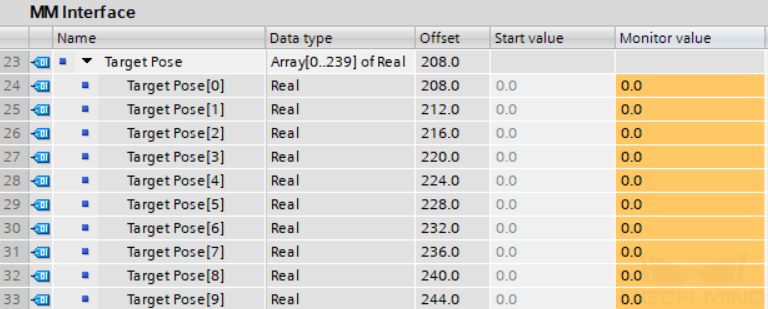

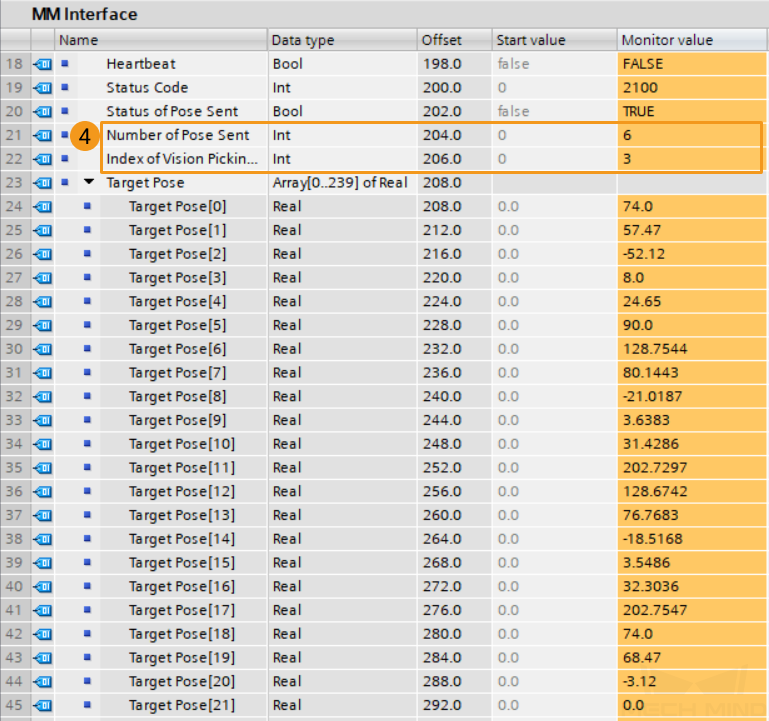

The returned data from Mech-Mind Interface is as follows. The value of “Number of Pose Sent” is 1, meaning 1 pose has been obtained. The pose data is stored in “TargetPose”.

Get Planned Path from Mech-Viz¶

Parameter Settings¶

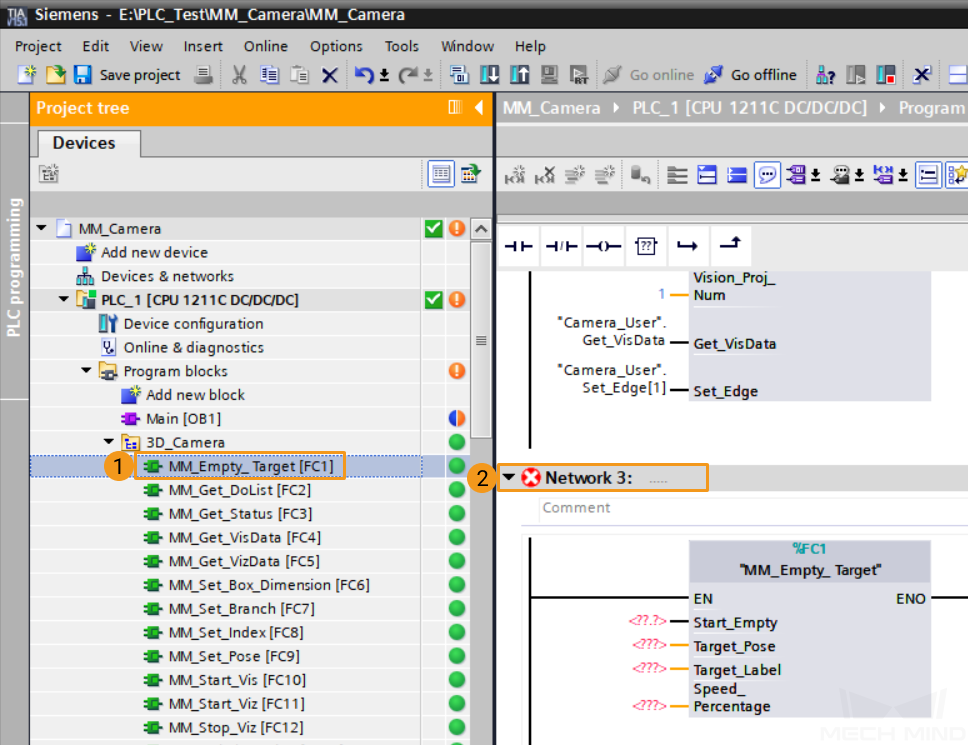

Drag the function MM_Empty_ Target to Network 2.

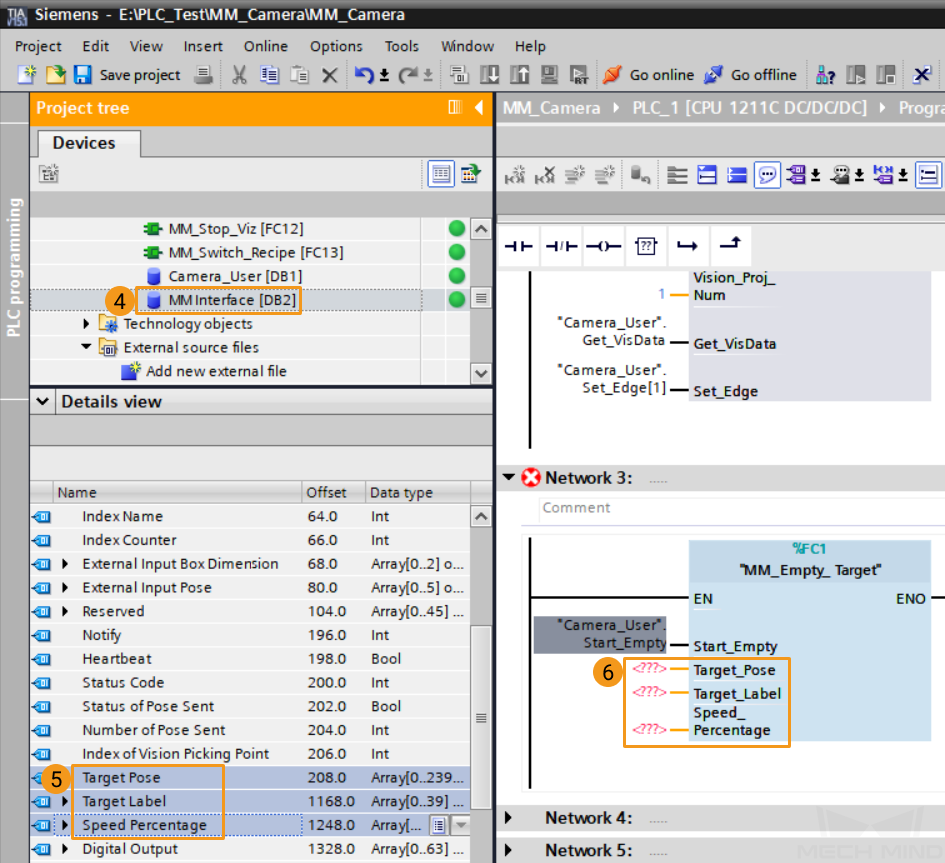

Click the data blocks Camera_User and Mech-Mind Interface respectively, and drag the parameters in the detailed view to the corresponding input-side ports of MM_Empty_ Target.

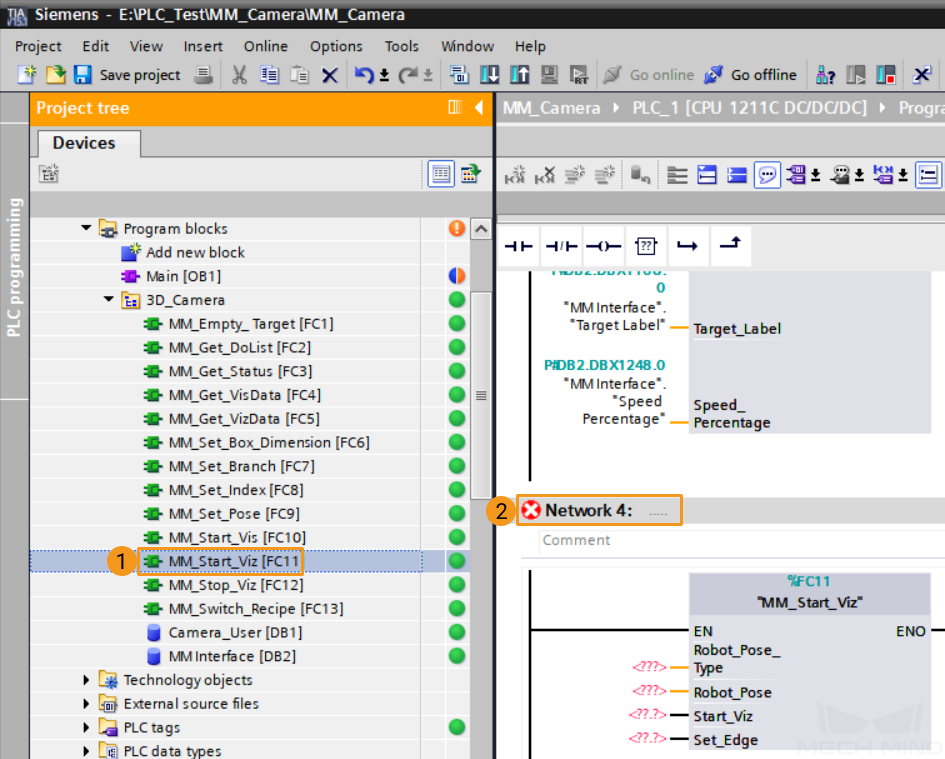

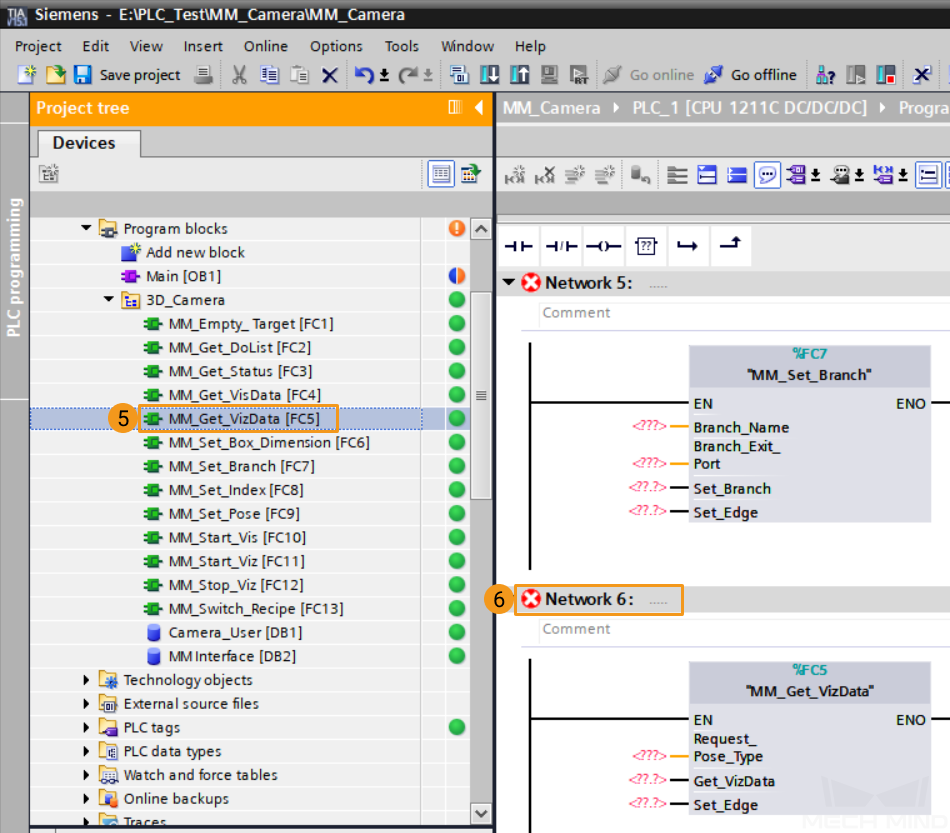

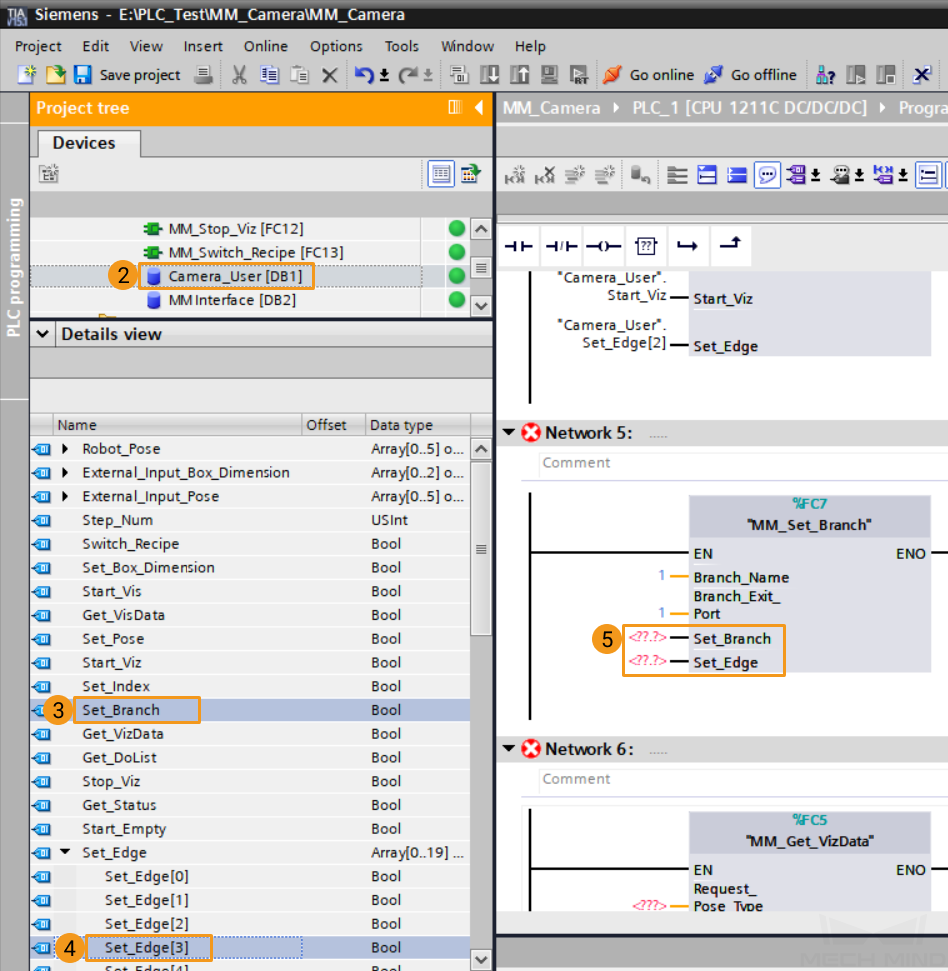

Drag and drop the functions MM_Start_Viz , MM_Set_Branch , MM_Get_VizData to Network 4, 5, and 6 respectively.

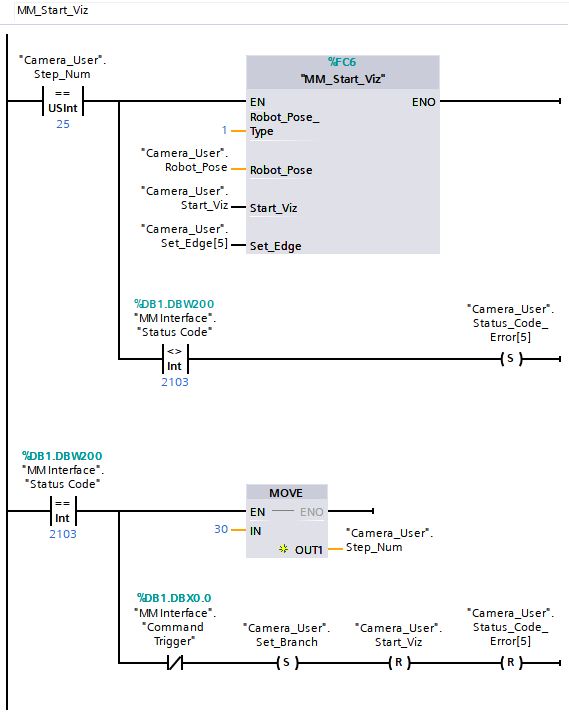

Set the type of pose expected from the robot. In this example, set the port value of Robot_Pose_Type to 0, indicating no image-capturing pose needs to be read from the robot (such as in the eye-to-hand mode). Click the data block Camera_User, and drag the parameters in the detailed view to the corresponding input-side ports of MM_Start_Viz.

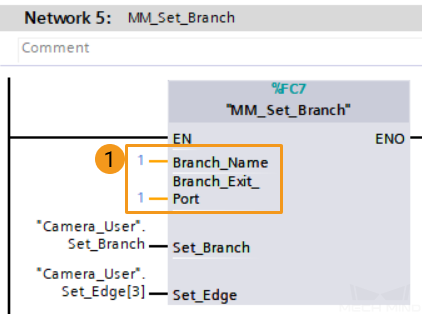

Set the branch parameters in the Mech-Viz project. In this example, set the port values of Branch_Name and Branch_Exit_Port to 1 respectively, which means that when the Mech-Viz project is controlled to execute to branch 1, it will continue to execute along exit 1. Click the data block Camera_User, and drag the parameters in the detailed view to the corresponding input-side ports of MM_Set_Branch.

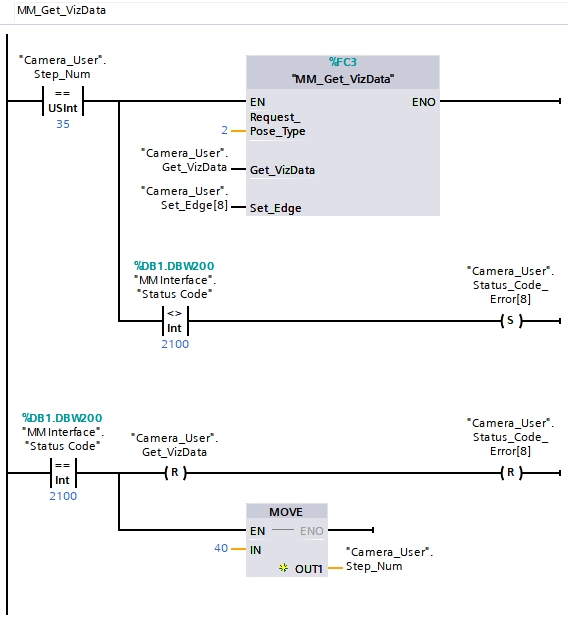

Set the expected type of waypoints on the planned path. In this example, set the port value of Request_Pose_Type to 1, indicating the expected waypoint pose type is JPs. Click the data block Camera_User, and drag the parameters in the detailed view to the corresponding input-side ports of MM_Get_VizData.

Under the project tree, right-click on PLC_1, select , and click Load in the pop-up download window to download the latest program to the PLC.

Trigger the Running of the Mech-Viz Project¶

In the main program window of Main [OB1], click Enable/Disable Monitoring

to enable monitoring.

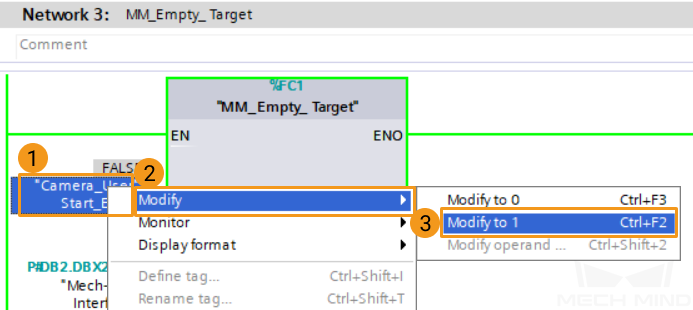

to enable monitoring.Right-click on the input-side parameter “Camera_User”.Start_Empty of MM_Empty_Target, set its value to 1 to empty the vision result obtained in the last round, and then reset its value.

Right-click on the input-side parameter “Camera_User”.Start_Viz of MM_Start_Viz, set its value to 1 to start the running of the Mech-Viz project and then reset its value. At this time, the parameter StatusCode of Mech-Mind Interface should have a returned value of 2103. Otherwise, an error has occurred, and please see Status Codes and Troubleshooting for further instructions.

Set the Mech-Viz Branch Exit¶

Right-click on the input-side parameter “Camera_User”.Set_Branch of MM_Set_Branch, set its value to 1 to specifiy the branch exit, and then reset its value.

At this time, the parameter StatusCode of Mech-Mind Interface should have a returned value of 2105. Otherwise, an error has occurred, and please see Status Codes and Troubleshooting for further instructions.

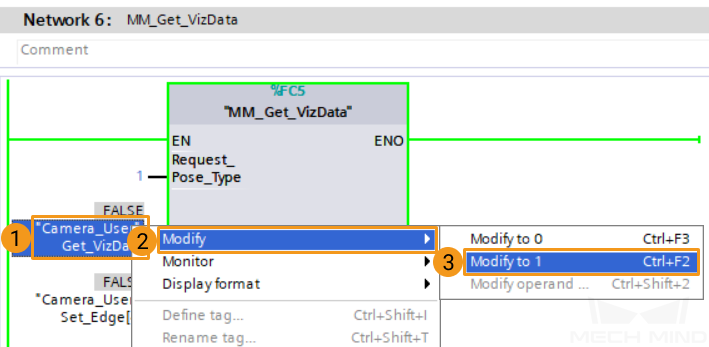

Obtain Planned Path from Mech-Viz¶

Right-click on the input-side parameter “Camera_User”.Get_VizData of MM_Get_VizData, set its value to 1 to obtain the planned path from Mech-Viz and then reset its value.

At this time, the parameter StatusCode of Mech-Mind Interface should have a returned value of 2100. Otherwise, an error has occurred, and please see Status Codes and Troubleshooting for further instructions.

The returned data of Mech-Mind Interface is as follows. The value of Number of Pose Sent is 6, which means that 6 sets of JPs data are obtained, and the data is stored in Target Pose. Index of Vision Move is 3, indicating that the position number of the vision point, i.e., the “Vision Move” Step in the path, is 3.