Pick Multi Carton + Parallel Suction Cups¶

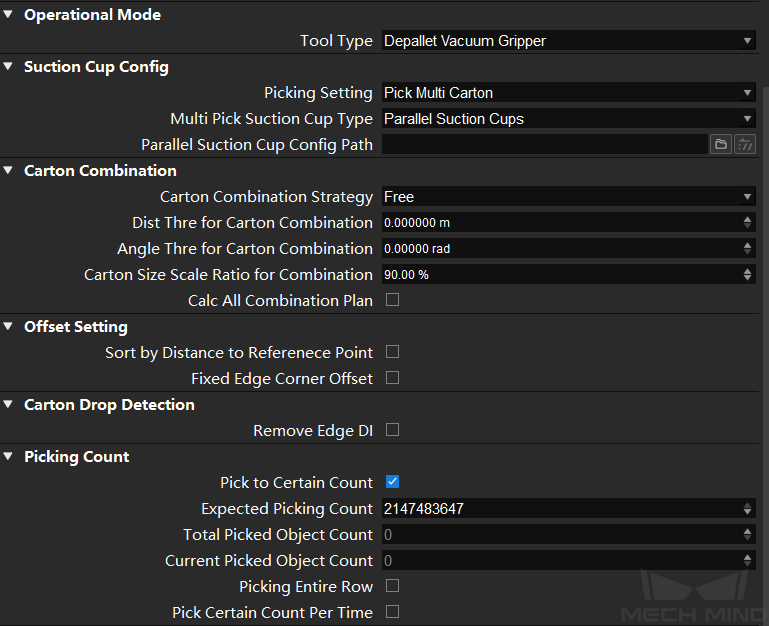

The parameters are shown below.

Suction Cup Config

- Parallel Suction Cup Config Path

Click

to select the suction cup configuration file. You can use the Depalletizing Vacuum Gripper to configure the suction cups and output a configuration file in JSON format.

to select the suction cup configuration file. You can use the Depalletizing Vacuum Gripper to configure the suction cups and output a configuration file in JSON format.

Carton Combination

- Calc All Combination Plan

- Select to calculate all possible carton combinations when different Carton Combination Strategies are used.Please refer to Carton Combination for detailed information.

Offset Setting

- Sort by Distance to Reference Point - Reference Point X/Y

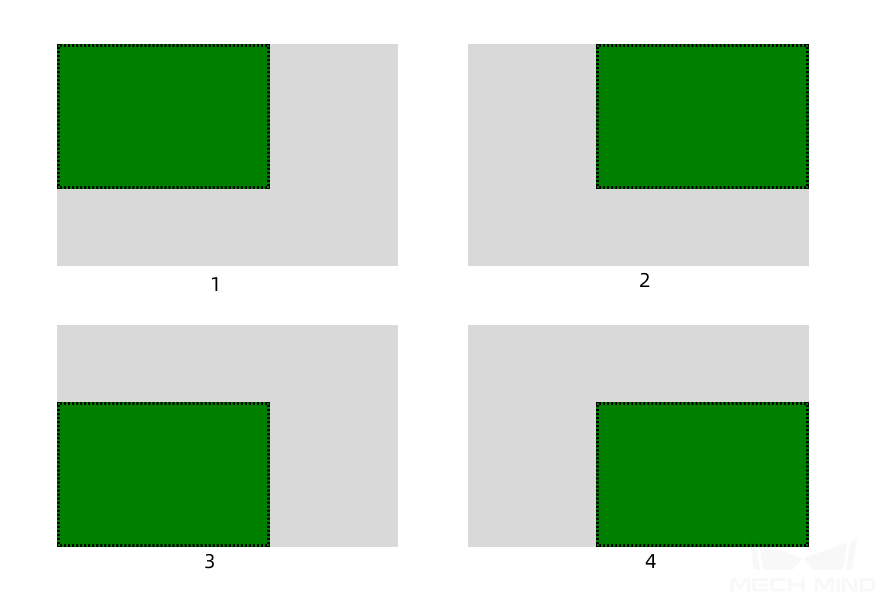

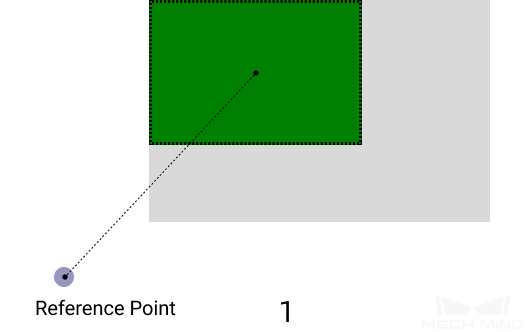

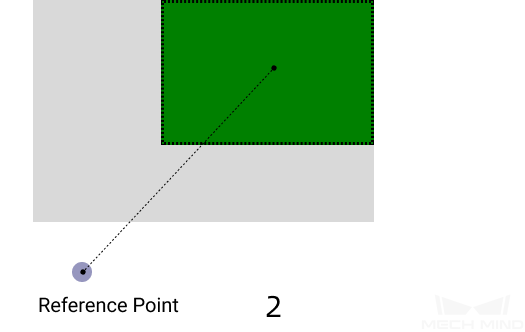

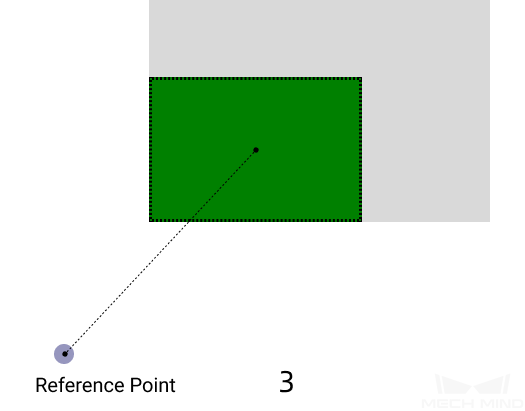

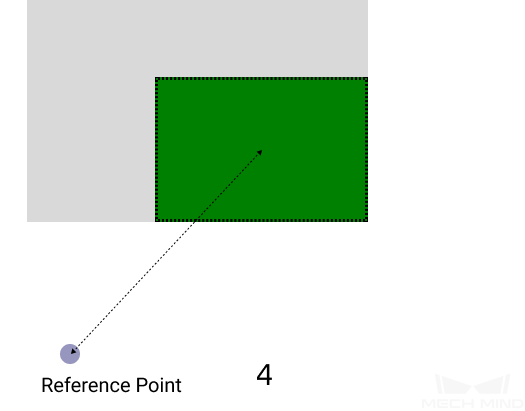

- Instruction: You need to set a reference point if you want to enable this parameter, and the robot will prioritize picking poses of which the suction cup is close to the reference point. This setting and the object symmetry settings cannot be enabled at the same time.Example:As shown in the figure (top view perspective) below, the green rectangles represent cartons, and the gray rectangles represent suction cups. There are four picking strategies in total.The reference point is in the lower left corner to the carton, and the relative position of the reference point and the carton is fixed. Picking poses of which the suction cup is nearest to the reference point will be tried first.Therefore, the picking poses in the figure below will be tried in the order of .

- Keep Only High Priority Offset - Max Plan Results Count

- Instruction: The default setting is 2. Please set the count according to the total planning results when a reference point is introduced.Example: If this option is enabled, only planning results No. 2 and No. 1 in the above example will be kept.

- Fixed Edge Corner Offset - Fixed Edge Corner Offset

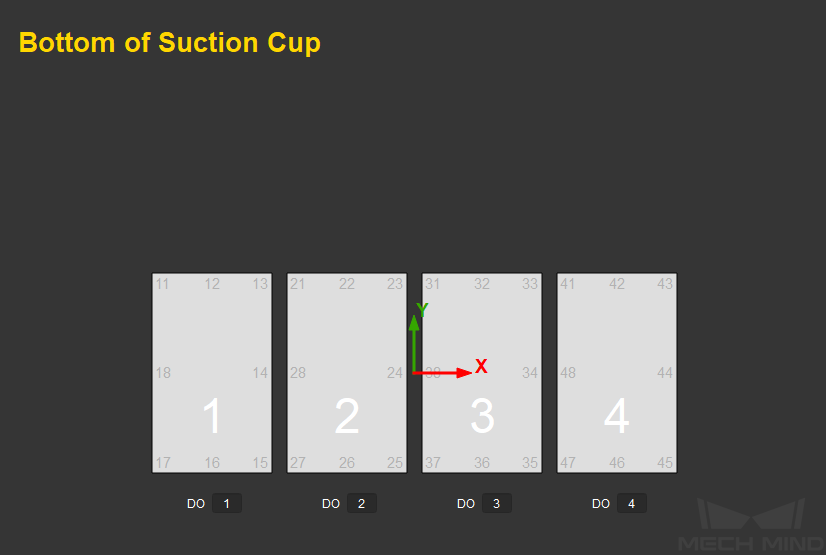

- Enter the edge corner label numbers.The numbering rules of the edge/corner: The first digit of the label number indicates the number of the suction cup, and the second digit of the label number indicates whether it is an edge or corner, where 1, 3, 5, and 7 represent the corner and 2, 4, 6, and 8 represent the edge. 0 represents the center of the suction cup.

Please refer to Offset Strategy for detailed information.

Carton Drop Detection

Application scenario:

In actual carton depalletizing projects, DI check points will be added on the working surface of the suction cups to monitor whether the cartons are picked successfully and whether the cartons are dropped by the robot.

Prerequisites:

Select the suction cup configuration file in . Please refer to Depalletizing Vacuum Gripper for more information about obtaining a suction cup configuration file.

If Set DO List is used in the project, select the Get Do List From VisualMove parameter, and select the corresponding visual_move.

If Check DI List is used in the project, select the Get DI List From VisualMove parameter, and select the corresponding visual_move.

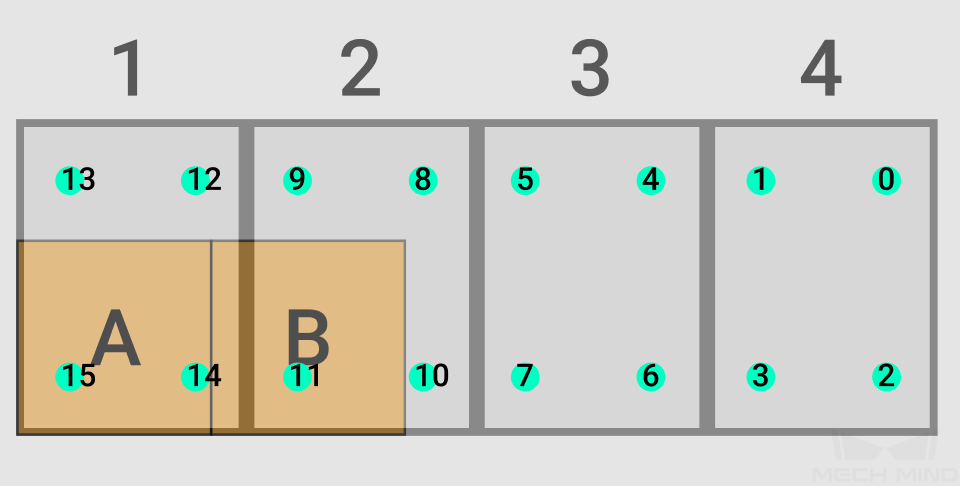

Example:

As shown in the figure below, the suction cup has 4 sections, and each section contains 4 DI check points. When the robot picks the combination of cartons A and B, the software will automatically determine which sections of the suction cup, that is, sections 1 and 2 in this example, should be started. Also, check points 8, 9, 10, 11, 12, 13, 14, and 15 will be used in the carton drop detection.

- Remove Edge DI

When DI check points are used in the carton drop detection and DI check points are at the edge of the carton, the software may mistakenly detect that the carton is dropped due to picking deviation, loose suction on the edge, deformation of the carton, or other reasons. Under such circumstances, you can set a Dist from Carton Edge To Remove DI to remove DI check points on the edge of the carton to avoid detection errors.

- Dist from Carton Edge To Remove DI

The distance inward from the carton edge, within which the DI check points will not trigger the carton drop detection. The part in which the DI will be removed is displayed in red in the 3D simulation area.

Picking Count

This parameter group is used to count the picked objects and calculate the rest objects to be picked. Once you enter an Expected Picking Count, the Total Picked Object Count and Current Picked Object Count will be calculated automatically.

- Expected Picking Count

The maximum number of picked objects.

- Total Picked Object Count

The number of picked objects, which is counted automatically and cannot be modified.

- Current Picked Object Count

The number of the currently picked object, which is counted automatically and cannot be modified.

- Picking Entire Row

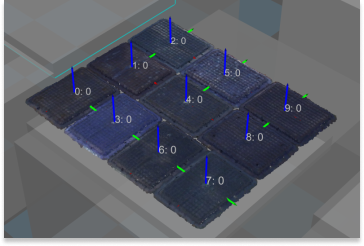

- Description: Once this parameter is enabled, the software will check whether there is another carton at the end of the row along the carton combination direction. If there is no other carton, the current carton combination will be kept, or else the carton combination will be discarded. For better performance, this parameter can be used with Carton Size Scale Ratio for Combination in Carton Combination.Example: The crates are combined along the Y-axis (in green) as shown below. The possible combinations include [0,3,6,7], [1,2], [4,5], and [8,9]. Since only [0,3,6,7] includes the entire row and there are no other cartons in the Y-axis direction, the carton combination [0,3,6,7] will be picked first.

- Pick Certain Count Per Time

This parameter specifies the number of objects picked at one time. Once this parameter is set, only combinations with the specified number of objects will be picked. If no combination meets the requirement, no object will be picked and the Step will take the Other failures exit port.

- Picking Count Per Time

The number of objects to be picked at one time. This value must be an integer starting from 1.