Mixed Pallet Pattern¶

Note

Contents of this Step are under maintenance. If you need more information about this Step with urgency, please contact us at docs@mech-mind.net.

Function¶

Automatically generate pallet patterns containing workobjects of various dimensions and perform palletizing.

Parameter Description¶

Move-Type Step Common Parameters¶

Please refer to General Parameters of Move-Type Steps for detailed information.

Held Workobject Collision Detection Settings¶

Please refer to Held Workobject Collision Detection Settings for detailed information.

Pallet Size¶

- Pallet X/Y/Z Len

Sets these parameters according to the actual pallet size.

- Pallet Z Overflow

During palletizing, boxes are allowed to exceed the height of the pallet pattern.

Example:

The height of the pallet pattern is 600mm and the “Pallet Z Overflow” parameter is set to 100mm, so the final height of the pallet pattern is 700mm. The known pallet pattern height is 450mm, the allowable pallet pattern height is 700mm - 450mm = 250mm.

IF the height of the box is greater than 250mm, it will not be possible to continue palletizing.

IF the height of the box is less than 250mm, it will be possible to continue palletizing.

Pallet Type¶

Online¶

Pallet Setting

- Gap Width

Sets the gap width of the boxes in the pallet pattern.

- Prior Corner

The preferred pallet angle when palletizing, which varies with the pallet pose.

OO

The corner of the pallet closest to the robot.

OY

The pallet angle in the positive Y direction of the robot with OO as the reference.

XY

The corner of the pallet furthest away from the robot.

XO

The angle of the pallet in the positive direction of robot X with OO as the reference.

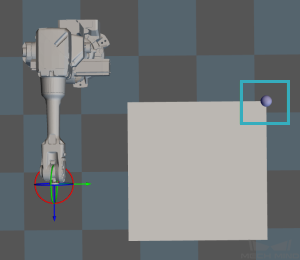

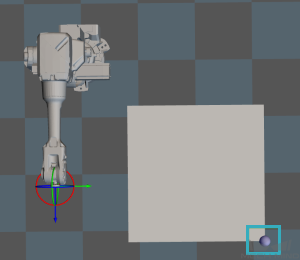

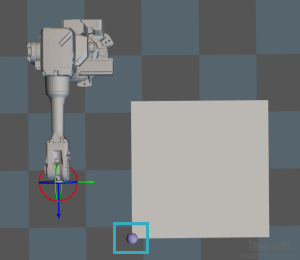

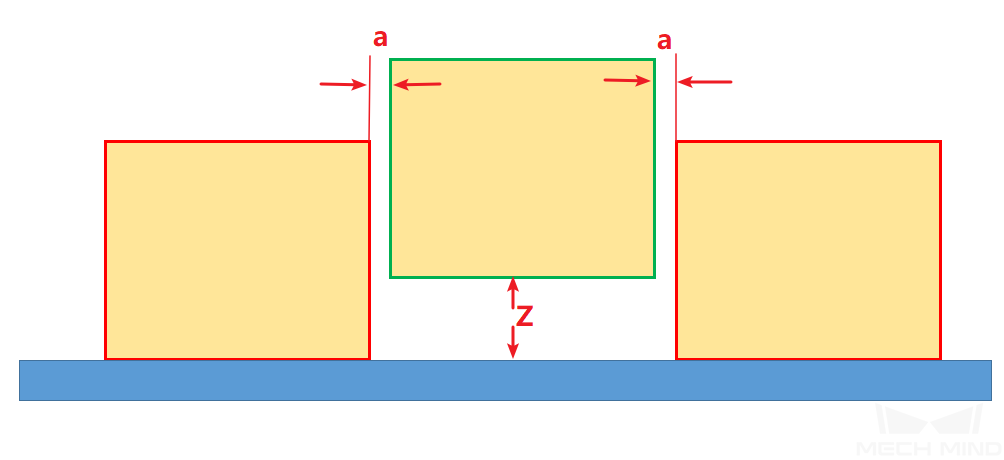

Placed By Drop

To reduce collisions, place short boxes between two taller boxes. Or when boxes are placed too closely together, place the boxes in free-drop mode.

- Enable Drop

If you check this parameter, the boxes will be placed in free-drop mode.

- Drop Height

When the box is at a certain height from the placement position Z, the box is allowed to be drop down.

- Drop Safe Margin

Minimum distance between the side of the box to be placed and the surrounding boxes.

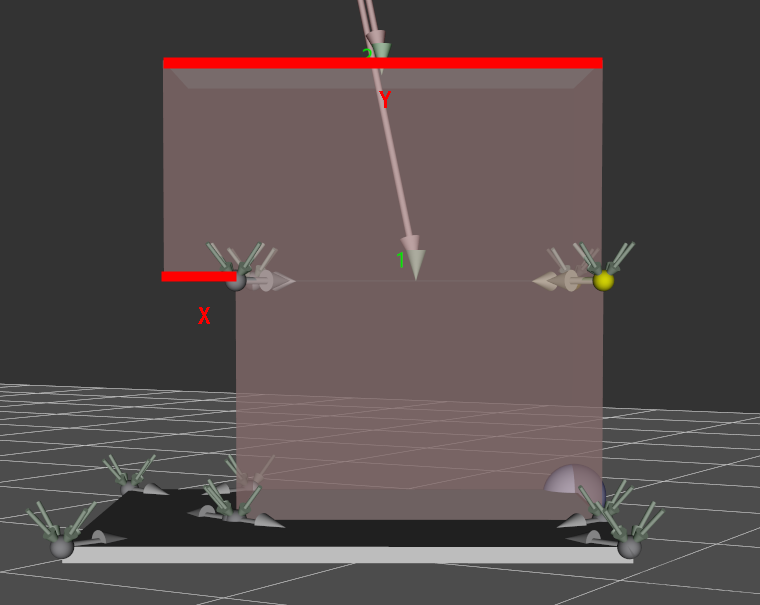

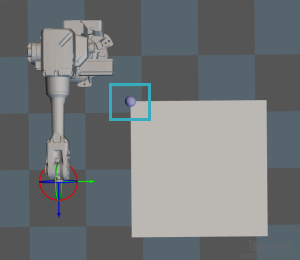

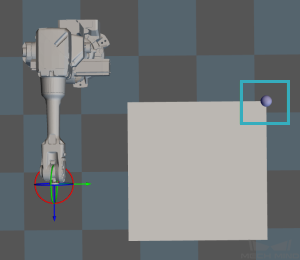

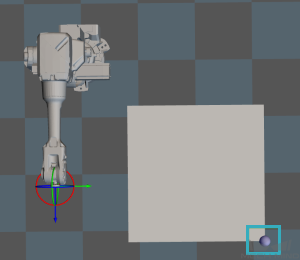

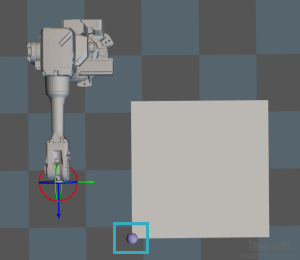

Z:Drop Height; a:Drop Safe Margin¶

Capture Twice to Update Carton Size

This step will estimate the height of the boxes and plan the palletizing according to the estimated height. After checking this parameter, when running to this step, it will take photos again to calculate the box height and use the box size calculated by two photos to plan the palletizing again.

Candidates Limit

- Candidates Limit Counts

This parameter is used to limit the total number of candidate locations for all boxes to speed up the subsequent path detection.

The candidate positions are the optional positions for planning palletizing. Assuming that there are 20 locations for robot path planning, if there is no limit, the robot will need to finish planning 20 times if there is a collision. If this parameter is set to 5, the robot will finish planning 5 times if there is a collision.

The default value is -1, which means that there is no limit on candidate positions.

- Candidates Limit Per Box Counts

This parameter is used to limit the total number of candidate locations for a single box to speed up the subsequent path detection.

The default value is -1, which means that there is no limit on candidate positions.

Box With Tags

- Tag on Boundary

Check this parameter when the box has a label on the side and the label must face outward when palletizing.

- Max Dist From Tag to Pallet Boundary

The maximum distance from the labeled side of the box to the pallet boundary.

Parameters for Find Candidates

- Allowed Excess

The width of the box beyond the edge of the pallet.

- Box Exceed Ratio

Upper level boxes are allowed to exceed the maximum percentage of the plane they are in.

- Layer Height Diff

When the size of the boxes to be placed on the upper level is larger than the boxes already placed on the lower level, the large boxes on the upper level are allowed to be placed on a plane where the height difference does not exceed this parameter.

- Sampling Rate

Sampling rate (sample/meter) when planning the box position. The higher the sampling rate the more accurate the result, but the slower it will be.

Recommended value: 200, 500, 1000

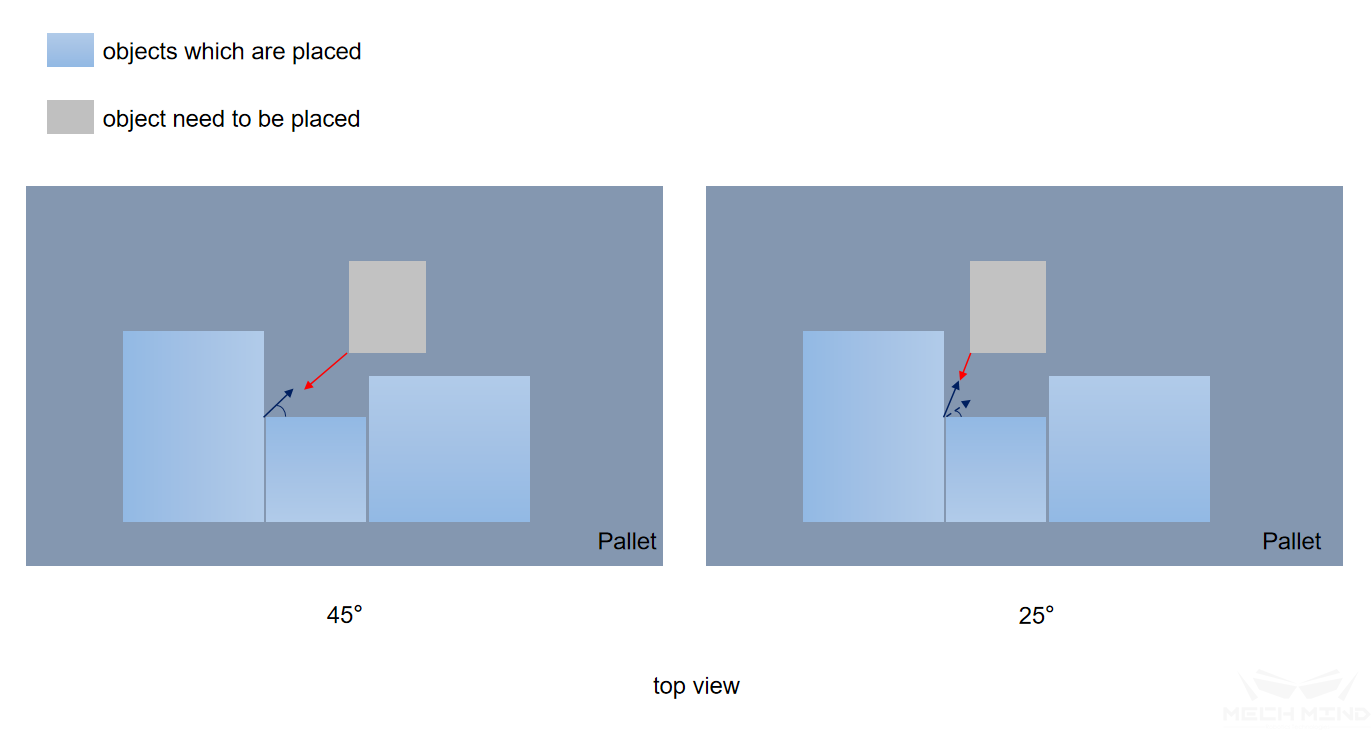

- Corner Free Angle

The angle between the box entry trajectory and the side of the adjacent box in the direction of the pallet projection.

If you set the value of this parameter too big, it may leave U-shaped free area when palletizing. If you set the value of this parameter too small, it may cause collisions when palletizing.

Recommended value is 15° – 30° .

- Enable Mid Point

The “mid point” is the middle point between the corner points of the box. when there is a U-shaped recess in pallet pattern, the box can be placed in the U-shaped recess from the direction perpendicular to the pallet.

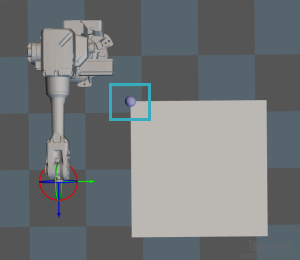

- Safe Radius

When determining the direction of entry of a corner point, detect whether there is an obstacle in the XOY projection plane within the radius of the corner point (unit: m) and in the direction of entry specified.

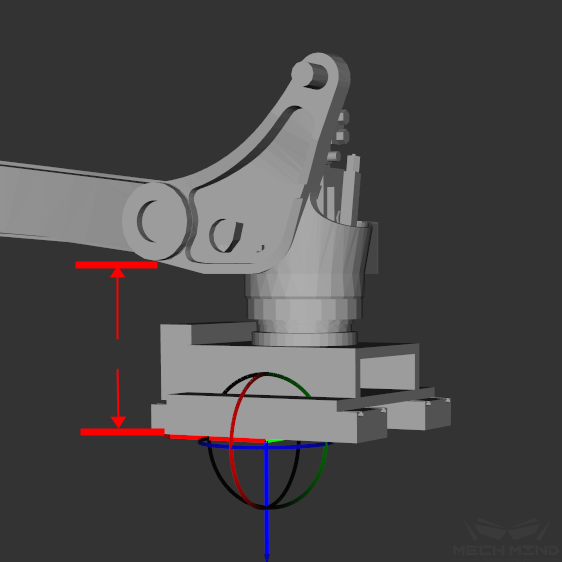

- End Effector Dim Z

Vertical distance from the lower surface of the end tool to the lower surface of the robot’s penultimate joint.

Mid Point Safe Gap

The minimum clearance value left on both sides when the box is inserted into the midpoint candidate position. This parameter can be set to a smaller value than the pitch width within the range of robot motion error and box size error. This parameter will significantly improve the flexibility and efficiency of palletizing when the operating mode is Online.

Scoring Weight

These parameters are all weighted and together determine the position of the box on the pallet.

- Adjacent Area Weight

The higher this value, the more likely it is that the position with the larger contact area between the side of the box to be placed and the side of the box already placed will be adopted.

- Support Area Weight

The higher the value, the easier it is to adopt a position with a larger support area (the smaller the area outside the lower surface).

- Base Height Weight

Base height refers to the Z-directional height difference between the bottom surface of the box to be placed and the pallet. The higher this value, the lower of the target position, the easier it is to place the boxes on a relatively low plane.

- Projected Dist to Corner Weight

The higher the value, the more likely it is to adopt a position where the diagonal position of the tray pattern is shorter from the projection of the preferred angle It is recommended to set this parameter in multiple intervals.

- Support Box Num Weight

The higher the value, the more likely a position that covers more boxes will be adopted, the more easily to form a stable pallet pattern but it will reduce compactness

- Bottom Area Weight

The higher the value,the easier it is to place the box on the placed boxes with the bigger bottom area.

- Dist to Edge Weight

The higher the value, the more likely the box will be placed on the edge of the pallet when palletizing.

Offline¶

Pallet Setting

- Gap Width

Sets the gap width of the boxes in the pallet pattern.

- Prior Corner

The preferred pallet angle when palletizing, which varies with the pallet pose.

OO

The corner of the pallet closest to the robot.

OY

The pallet angle in the positive Y direction of the robot with OO as the reference.

XY

The corner of the pallet furthest away from the robot.

XO

The angle of the pallet in the positive direction of robot X with OO as the reference.

- Offline Method

Best Fit: Select this option when stacking boxes of different sizes with large variations in size. The shape of the stack corresponding to this option is not as neat as the other options.

ByStack: Stack the boxes according to their size or type. Boxes within the same stack can be sorted according to certain rules.

ByLayer: Boxes of the same size will be placed on the same layer first. If a plane is not filled, the plane will be divided into four areas, and only one type of box will be placed in each area.

In Batches: After the boxes of one type of SKU are stacked, the boxes of another type of SKU are allowed to be stacked. This option can be used in the scenario where AGV is used for feeding, which can effectively reduce the feeding times of AGV.

- Offline Current Pallet Index

Specifies the index of the pallet currently being viewed.

- Min Box Length

When the box size is small, the planning time for offline mixing may be longer. Setting this value prevents order entry errors from causing long calculation times.