Introduction to Mech-Mind Vision System¶

Mech-Mind Vision System is a complete set of 3D vision solution provided by Mech-Mind. It provides rich application scenarios such as workpiece loading, depalletizing and palletizing, locating and assembly, piece picking, and quality inspection, and is widely used in automobiles, logistics, supermarkets, heavy industry and other fields.

Introduction¶

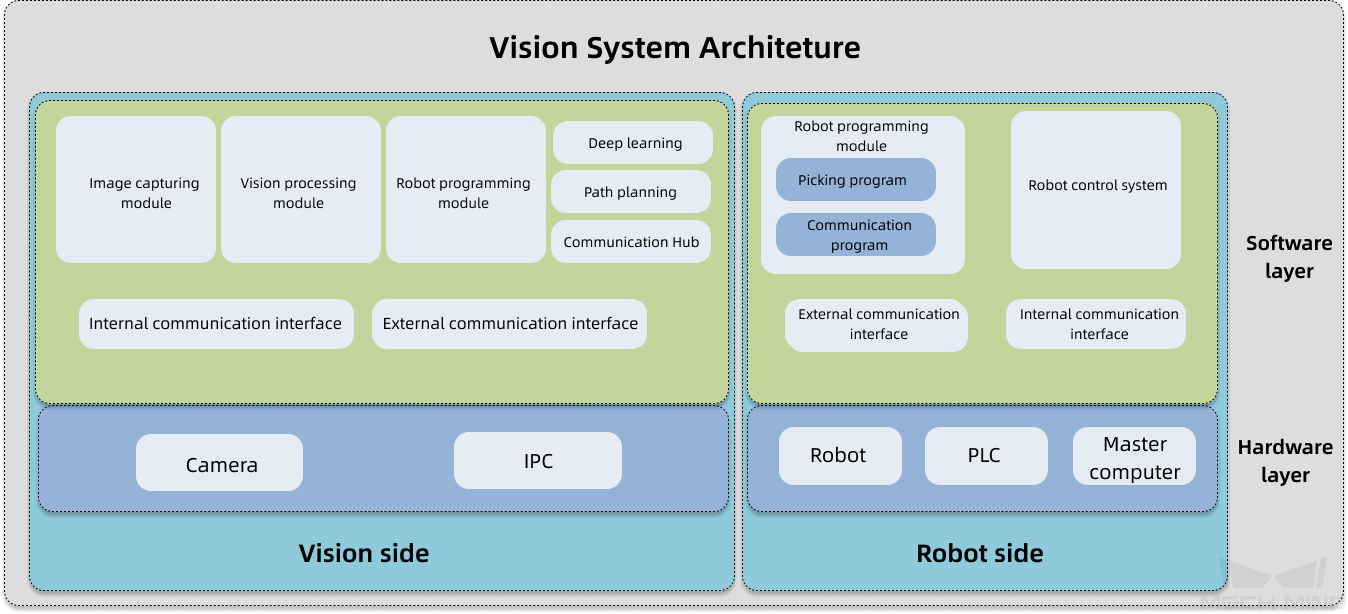

Mech-Mind Vision System consists of the vision side and the robot side. The vision side captures images, carries out vision processing, path planning and other processes, and then outputs the vision result or planned robot path for the robot side. The robot side performs intelligent production under the guidance of the vision side.

At the hardware level, the vision side includes Mech-Mind 3D industrial cameras, IPC (industrial computer) and a series of accessories. At the software layer, the visual side is the Mech-Mind software suite, which provides functional modules such as communication, image capturing, vision processing, path planning, and robot programming.

At the hardware level, the robot side is mainly composed of robot unit (robot body, robot controller, teaching pendant), PLC (Programmable Logic Controller) and host system. At the software level, the robot side interacts with the external communication interface of the vision side through the robot communication program, and obtains the vision result or robot planning path output by the vision side through picking or other applications.

Mech-Mind Vision System allows the robot side to integrate with the vision side through a variety of communication modes and protocols, which meets the deployment requirements of various application scenarios. For the supported communication modes and protocols, refer to Communication Overview.

Tip

For robots or PLCs that have adapted to Mech-Mind Vision System, Mech-Mind provides robot programs (namely, communication programs, calibration programs, and picking or other application programs) that can be directly installed on the robot side. For robots or PLCs that have not adapted to Mech-Mind Vision System, you need to develop the corresponding robot programs yourself.

Common Application Scenarios¶

Mech-Mind Vision System provides rich application scenarios, mainly including:

3D vision guided workpiece loading

3D vision guided depalletizing and palletizing

3D vision guided locating and assembly

3D vision guided piece picking

3D vision guided quality inspection

Mech-Mind provides an online solution library, which provides instructive and reproducible typical solution cases for each application scenario, so that you can quickly learn and get started with Mech-Mind Vision System.

Mech-Mind Software Products¶

Mech-Eye SDK: Software Development Kit for Mech-Eye Industrial 3D Cameras. Mech-Eye SDK includes camera application program interface Mech-Eye API, camera configuration and data visualization software Mech-Eye Viewer, and user manual. It helps obtain images and point clouds that fit requirements using Mech-Eye Industrial 3D Cameras.

Mech-Vision: A cutting-edge machine vision software. Through its fully graphical interface, advanced machine vision applications such as piece picking, high precision positioning, assembly, industrial inspection/measurement, and automatic path planning can be completed without code writing.

Mech-Viz: Robot path planning software. It uses the information including the point clouds and workpiece positions provided by the 3D vision to intelligently plan the robot path for picking, carrying, and palletizing, etc.

Mech-DLK: Deep learning software. With a variety of built-in industry-leading AI algorithms and through intuitive and simple UI interactions, it helps customers solve complex problems, including overlapping object recognition, highly difficult defect detection, and product grading and classification, etc., thus helping improve production efficiency and yield, and reduce labor costs. It is suitable for industries including consumer electronics, new energy, automobiles, home appliances, logistics, etc.

Mech-Center: Communication hub and control center. It provides standard interface protocols and can help customers customize communication services, thus implementing communication with external devices and jointly completing smart manufacturing tasks with vision-guided robots.