Illumination Control¶

When structured-light 3D scanners are used to generated 3D point clouds or used for deep learning, the light conditions affect the effect and stability of visual recognition.

For the 3D point cloud imaging, the point cloud quality is better when the light is even and the surface brightness of the object is low. In the actual environment, the maximum brightness for metal parts is recommended not to exceed 600lux; the surface brightness of boxes and sacks is recommended not to exceed 800lux; in other scenes, the maximum brightness should be kept below 500lux to ensure the ideal quality of point cloud. Adding a uniform surface light source in a dark room is the most ideal and stable method to control brightness. In this environment, the brightness of the surface of the workpiece can keep stable and does not show light and dark variations. For the non-darkroom environment, it is recommended to use a shading and supplemental light solution to improve the quality of 3D point cloud.

For the deep learning, ideal conditions includes a stable lighting environment, a clearly visible surface of the workpiece is clearly visible, and a stable brightness. In the actual environment, the ambient light changes over time, which may affect the recognition results of the deep learning. Reasonable use of the shading and supplemental light solution can effectively control the changing of ambient light and stabilize the recognition results of deep learning.

Tip

The white ordinary LED light with a color temperature of 6000k is generally used as light source.

In the actual factory environment, the following points should be checked and guaranteed:

White balance: The colors in the 2D image should be similar to the images observed via naked eyes; otherwise it is required to adjust the white balance of the camera;

Light intensity: There should be no direct sunlight and other strong infrared light source on site;

Reflection: The lighting on site should be even and soft; strong light or complex light directly on the workpiece surface should be avoided;

Stability: The lighting on site must be stable to avoid great differences in light intensity during the day and night.

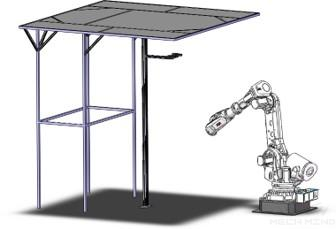

If the above points cannot be satisfied, it is necessary to consider the using of the shading and supplemental light. The following is the scheme for shading: