Label the Training Data¶

Create Label(s)¶

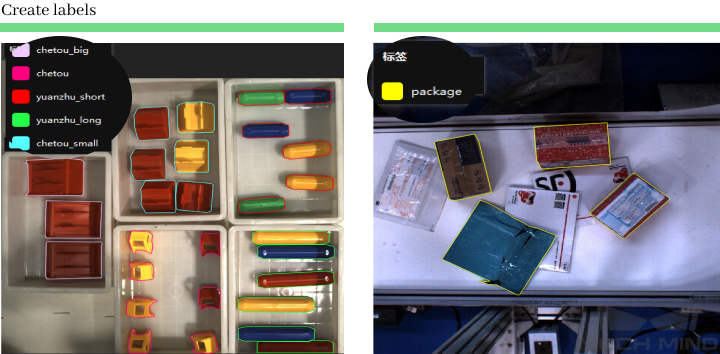

Please confirm whether the project requires the classification of objects. If so, please create multiple labels, each corresponding to an object class; otherwise, please create one label.

Figure 1. Cases of classification with multiple labels and no classification with a single label¶

Attention

Label names should be relevant to the objects and easily recognizable. Please do not use meaningless names like a, b, tmp, etc. Label names should only include letters or numbers.

Determine Method of Labeling¶

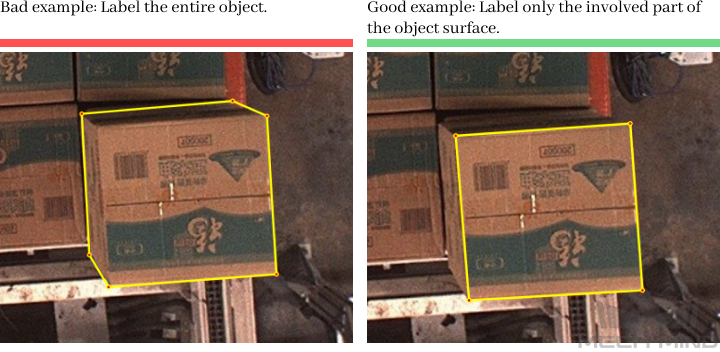

Label the contour of the upper surface: Suitable for orderly-placed and regularly-shaped objects, such as cartons, medicine boxes, rectangular workpieces, etc. Pick points are calculated based on the contour of the upper surface.

Figure 2. Label the contour of the upper surface¶

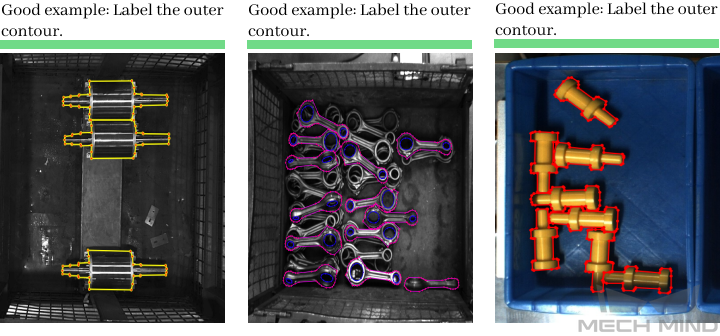

Label the contour of the entire object: Suitable for sacks, various workpieces, etc. Labeling the contour of the entire object is a general labeling method.

Figure 3. Label the contour of the entire object¶

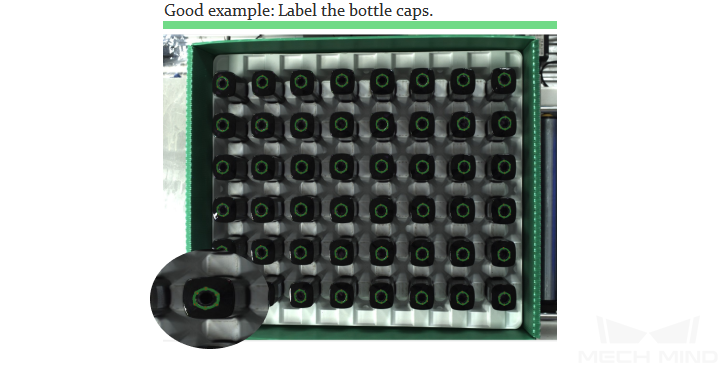

Special cases: Some picking tasks involve special end effectors and/or picking methods.

Case #1: The suction cup needs to fit perfectly with the bottle caps (requires high accuracy), thus only the contour of the bottle caps needs labeling.

Figure 4. Only label the bottle caps¶

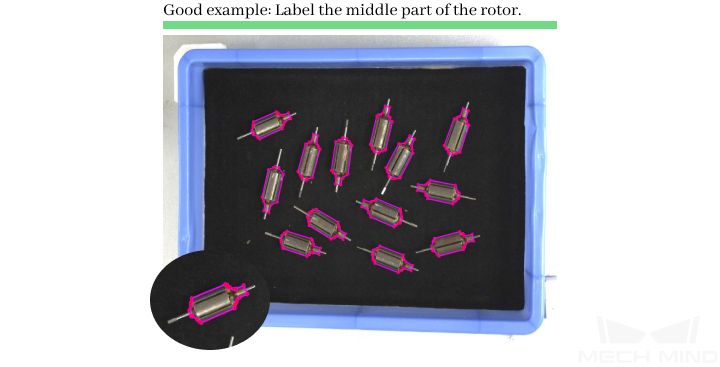

Case #2: The rotor picking task involves distinguishing the orientation of rotors. Only the middle parts where the orientation is easily recognizable need labeling and the thin rods at both ends should be excluded.

Figure 5. Only label the middle parts of rotors¶

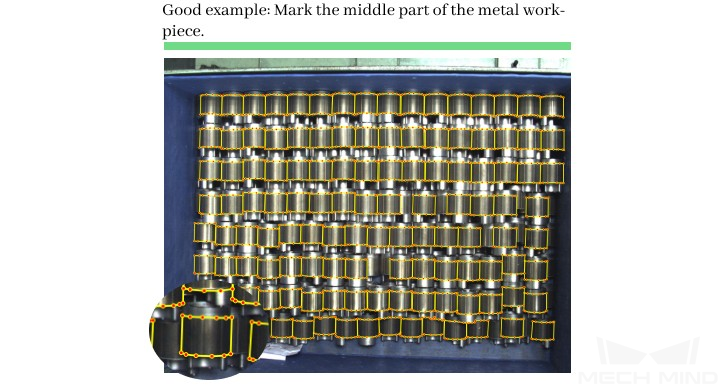

Case #3: The pick point is required to be in the middle part of the metal workpiece, so only the middle parts need labeling, and the two ends should be excluded.

Figure 6. Only label the middle parts of metal workpieces¶

Use Mech-DLK to Label Data¶

Different algorithms require different methods of data labeling. Please see Data Labeling in Mech-DLK for detailed instructions.

Attention

Please make sure to check the labeling quality: After labeling, be sure to check whether all images have been labeled and verify whether every label corresponds with the labeled object. Labeling errors act as counterexamples in the dataset and will adversely affect the training process and the model performance.

The quality of labeling should be evaluated in terms of completeness, correctness, consistency, and accuracy:

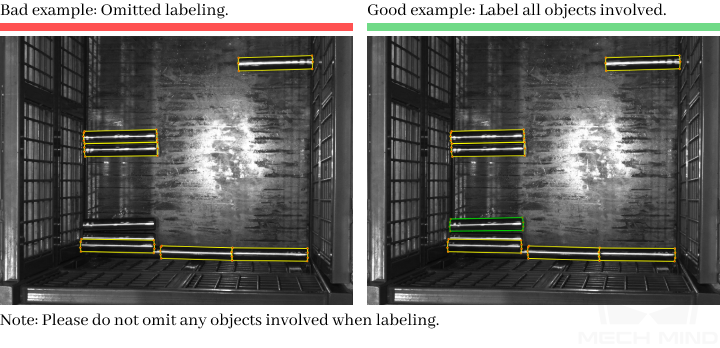

Completeness: Label all objects that meet the labeling rules without omission.

Figure 7. Completeness of labeling¶

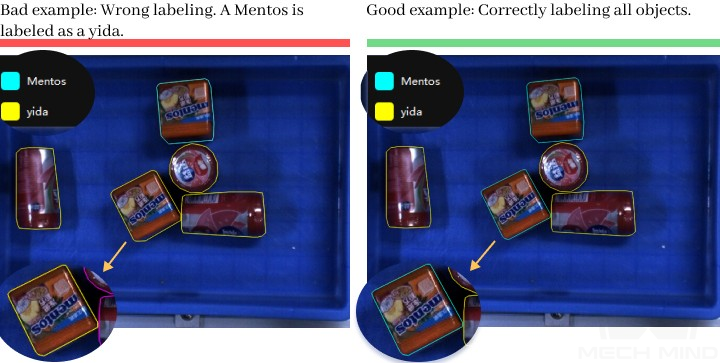

Correctness: Ensure that each object correctly corresponds to its label, without any mismatches between objects and their labels.

Figure 8. Correctness of labeling¶

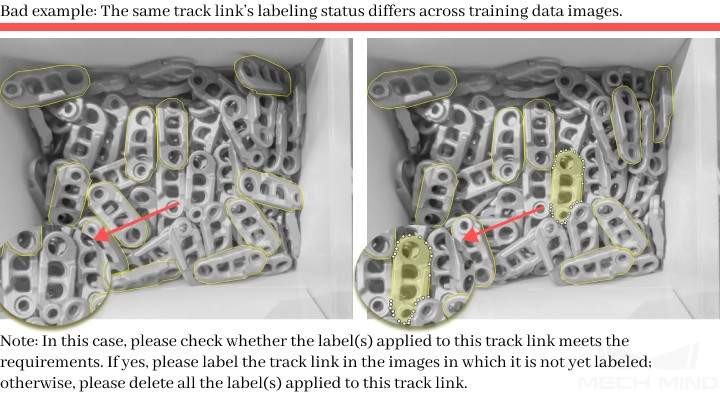

Consistency: All data should be labeled under the same rules. For example, if the labeling rules stipulate that only objects with 85% of the entire surface exposed should be labeled, then all objects that meet this rule should be labeled without exception.

Figure 9. Consistency of labeling¶

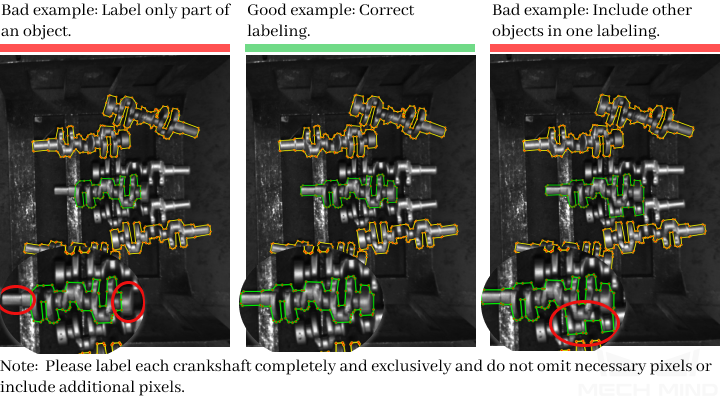

Accuracy: The drawn contour of the labeled object should closely fit the actual outline of the object, not excluding parts of the object or including parts of another object.

Figure 10. Comparison of different labeling accuracies¶