RobotWare7 Setup Instructions¶

Check Controller and Software Compatibility¶

Controller: OmniCore.

Controller system software version: RobotWare 7.3 or higher

Control module option: 3114-1 Multitasking

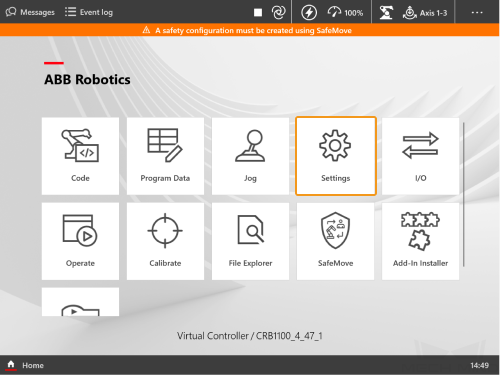

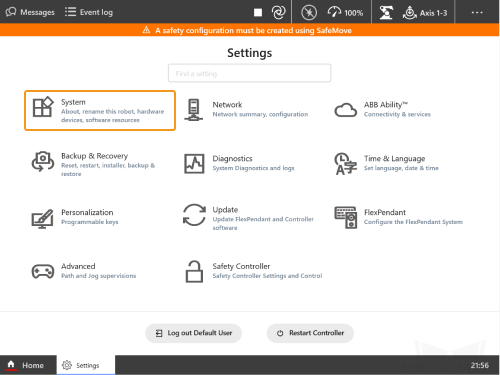

In the Home interface of the teach pendant, tap to check the RobotWare version.

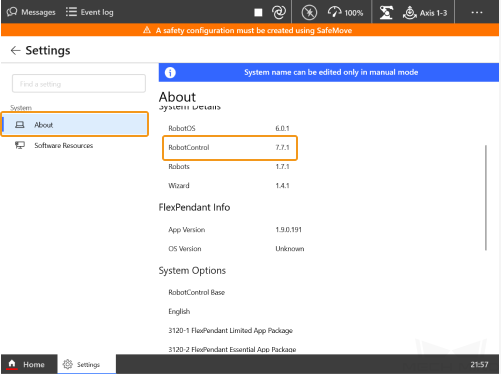

Tap About and you can confirm the RobotWare version in System Details.

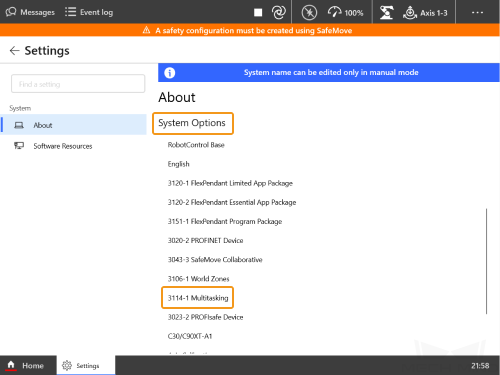

Check whether 3114-1 Multitasking is in the System Options.

Attention

The robot cannot be connected via Master-control if the system version does not meet the requirement.

Set up the Network Connection¶

Hardware Connection¶

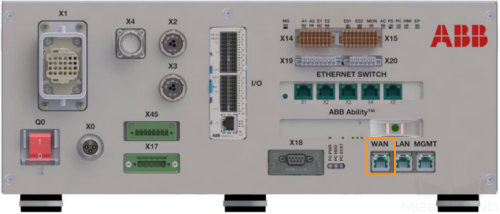

Plug the Ethernet cable of the IPC into the WAN port of the robot controller, as shown below.

IP Configuration¶

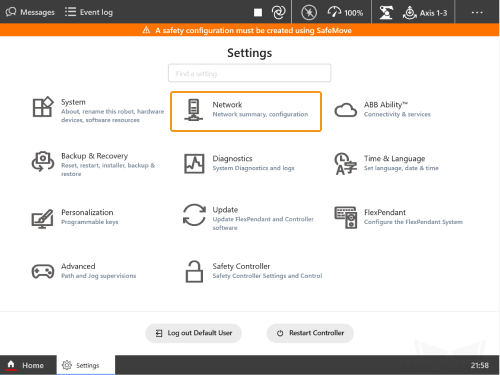

In the Home interface of the teach pendant, select .

Select Use the following IP address, and enter the IP Address, Subnet Mask, Default Getaway. The IP address of the robot should be in the same subnet as that of the IPC.

Attention

The Ethernet cable must be connected to the WAN port. When setting the IP, be careful to distinguish between the robot IP address of the WAN port and that of the LAN port.

Load the Program Files¶

Prepare the Files¶

Copy the program files into a USB flash drive. Please locate the folder where Mech-Mind Software Suite is installed and the files are stored in Mech-Center-xxx/Robot_Server/Robot_FullControl/abb/server on ABB.

Folder |

Description |

config_robware7 |

Robot configuration file that defines the signals required by the Master-control, the autoloaded module, and task types |

MM_robware7 |

The robot program module |

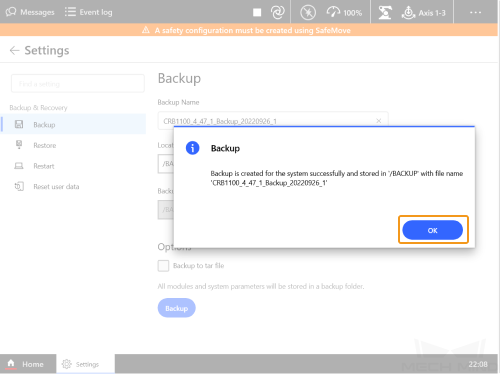

Backup¶

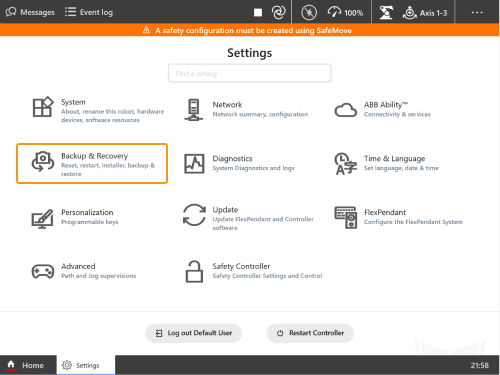

Before operating the robot, please follow the backup instructions below to back up the system so that the robot system can be recovered if a misoperation occurs.

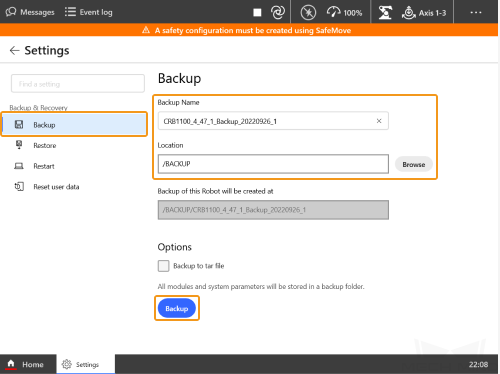

Select in the Home interface.

In the Backup window, modify the Backup Name and Location and then tap Backup.

Click OK in the pop-up window to complete the backup.

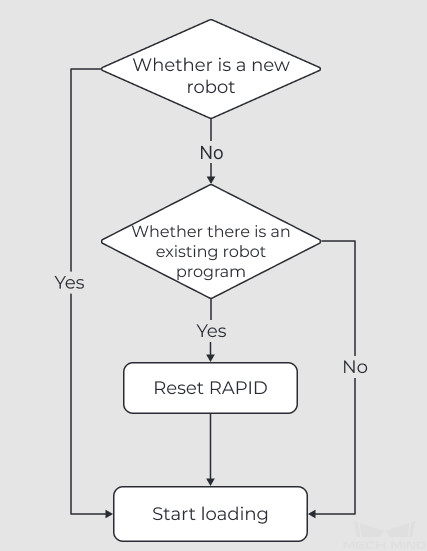

Reset¶

Note

There are two types of resets, which are resetting the system and resetting RAPID.

Resetting the system will restore the default system parameters and RAPID program, and the I/O configuration will be reset too. If a communication board or other communication devices are used, they should be re-configured after the system is reset.

Resetting RAPID will delete the current RAPID program and data, while the system parameter settings will be retained.

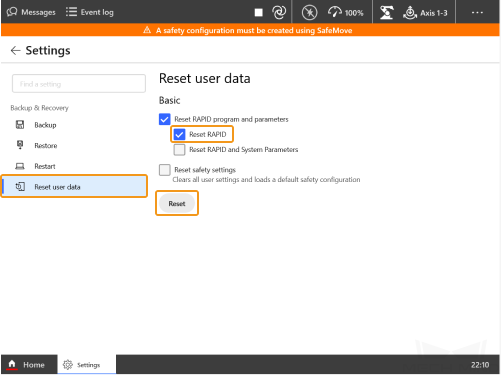

Reset RAPID¶

Please determine whether you should reset RAPID according to the following flowchart.

Select in the Home interface.

In the Reset user data window, select Reset RAPID, and then tap Reset.

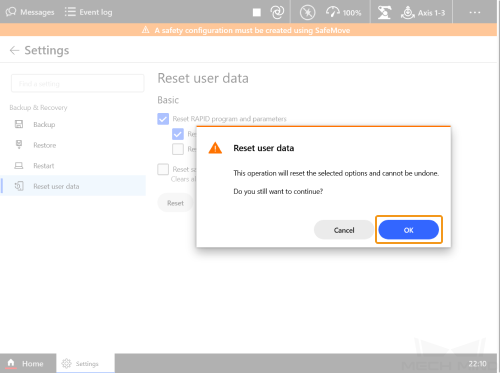

Click OK in the pop-up window.

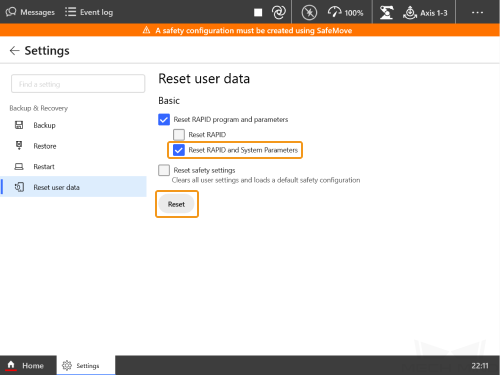

Reset the System (use with caution)¶

Select in the Home interface.

In the Reset user data window, select Reset RAPID and System Parameters, and then tap Reset.

Click OK in the pop-up window.

Load the Files to the Robot¶

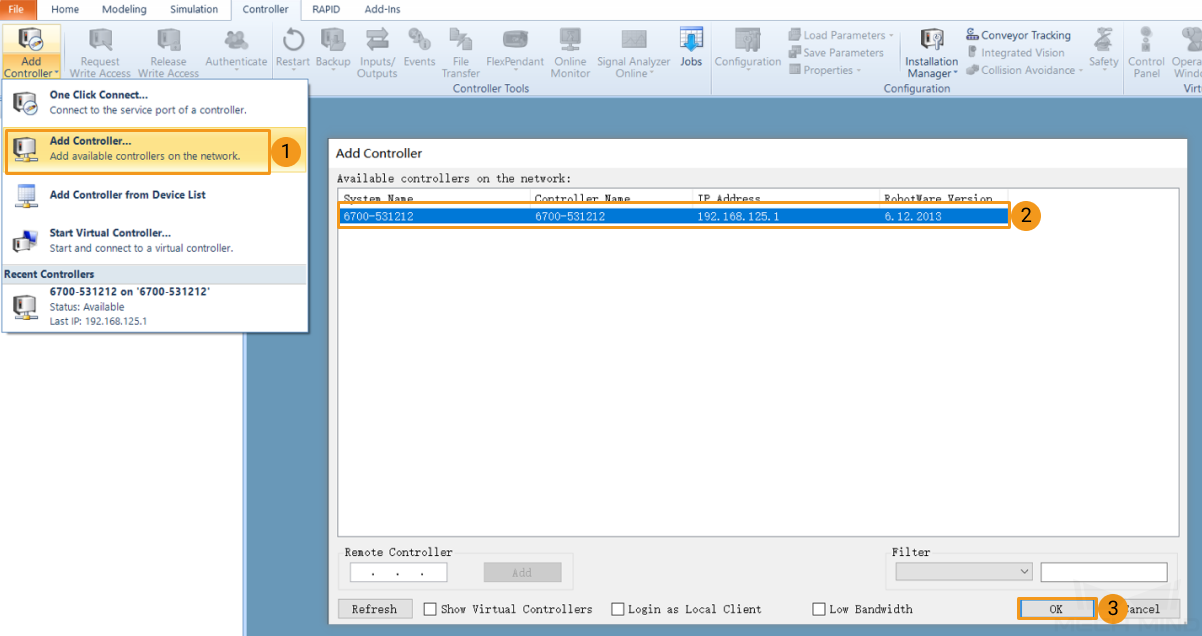

Open RobotStudio, since the Ethernet cable is connected to the WAN port of the controller, click Add Controller and then select the controller and click OK. After the controller is added successfully, the controller management port will be connected automatically.

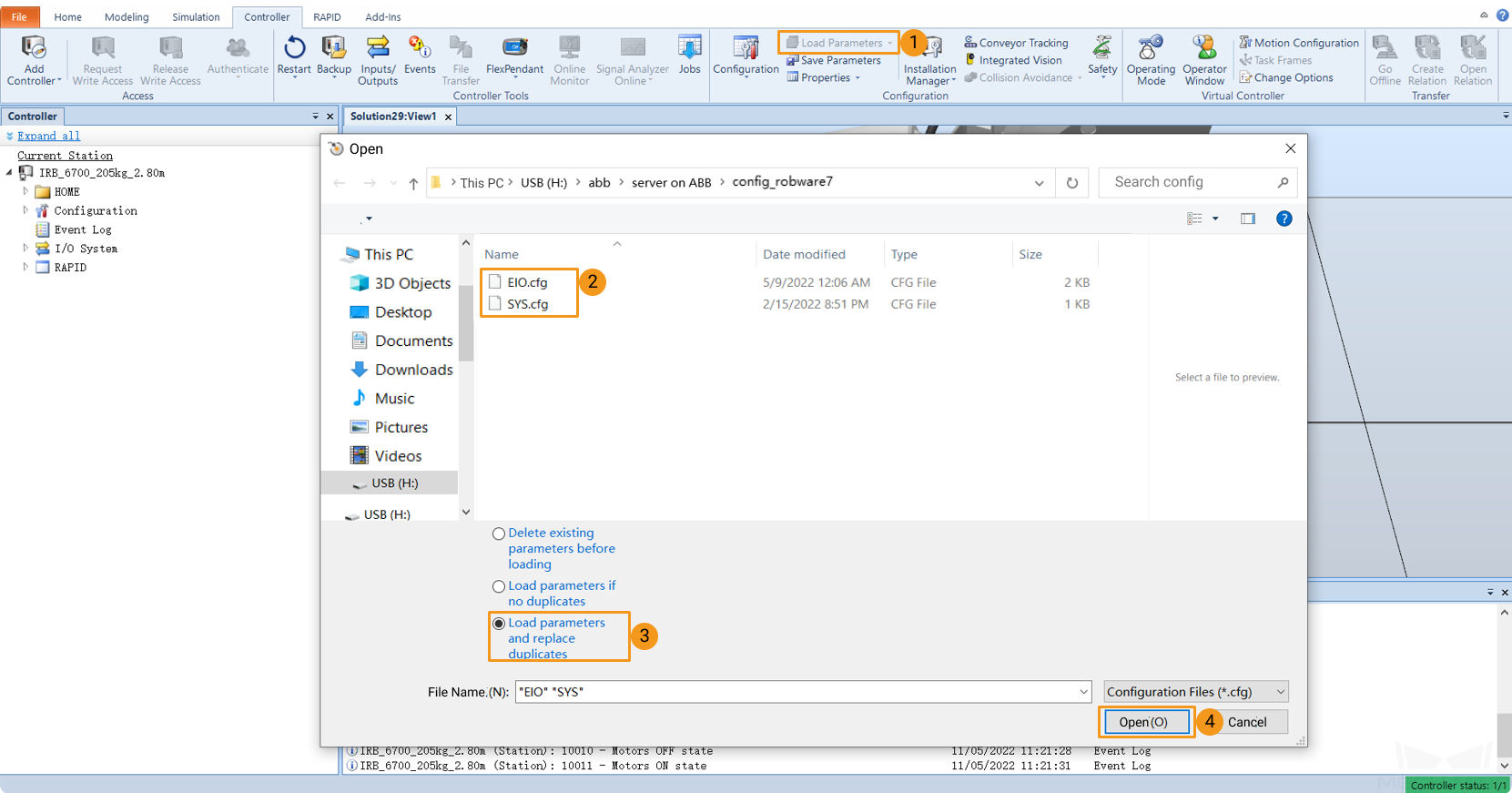

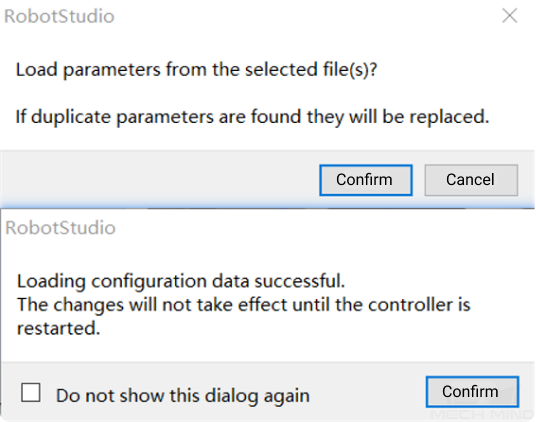

Import the two configuration files in the config_robware7 folder as shown below.

Select Confirm in the pop-up windows.

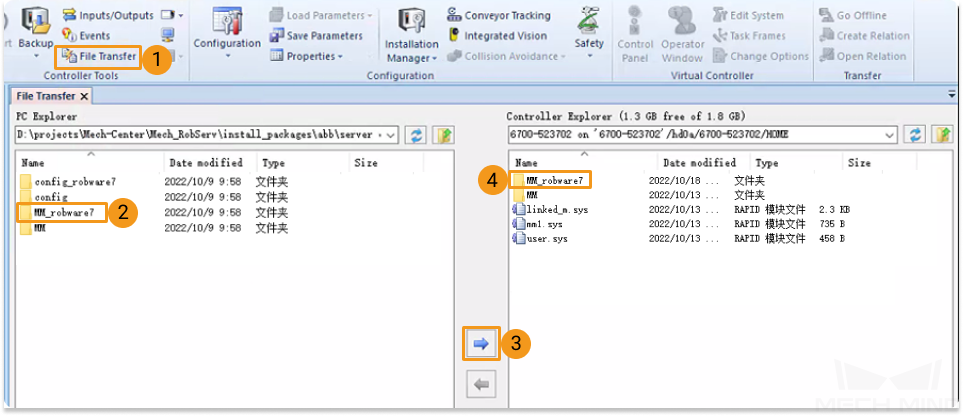

Follow the steps as shown in the figure below to copy the entire MM_robware7 folder and paste it to the HOME directory of the robot system.

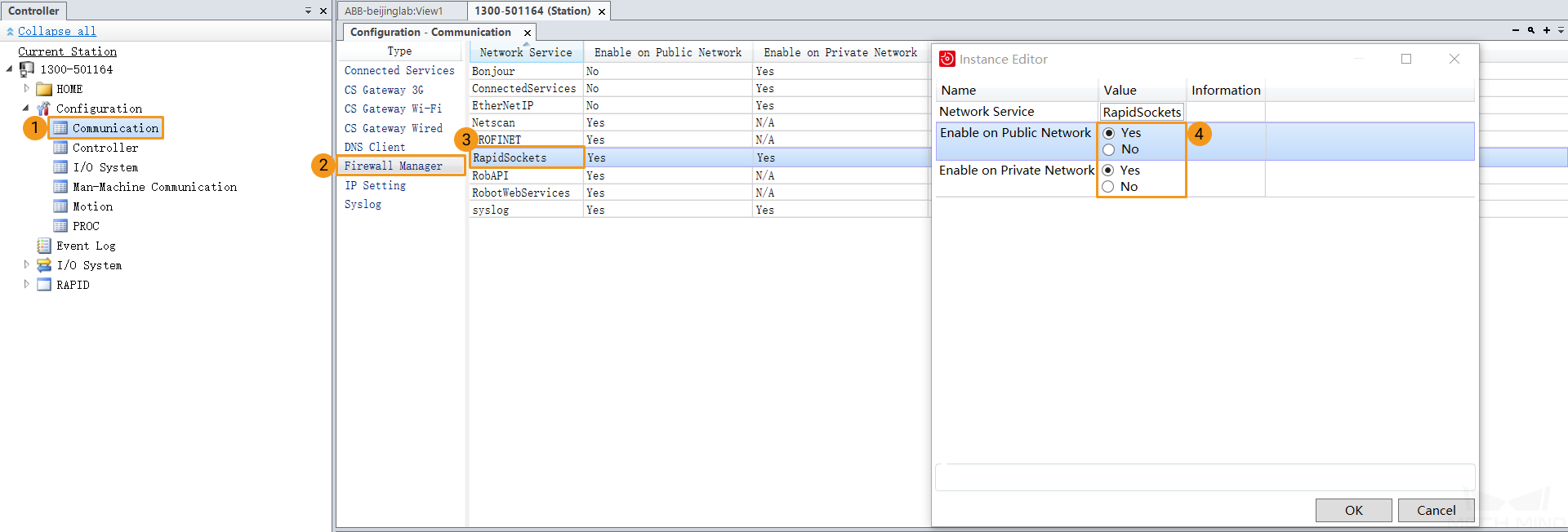

Follow the steps as shown in the figure below to enable the RapidSockets network service.

Modify the safe zone threshold (in mm) in the safe_area.mod program according to the actual on-site work space of the robot.

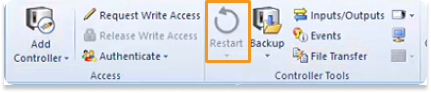

Click Restart to complete loading the program files.

Run the Program¶

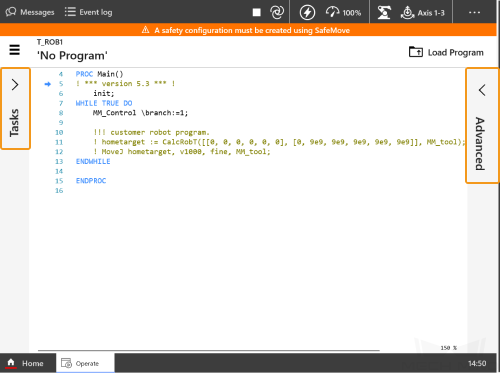

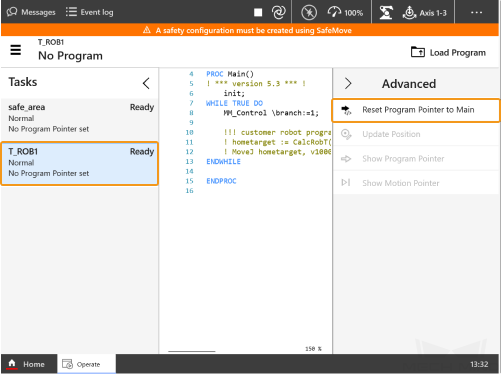

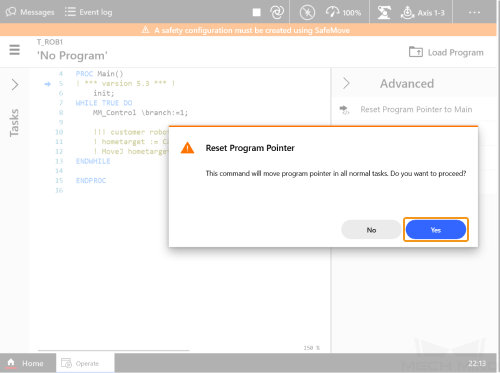

Reset the Program Pointer

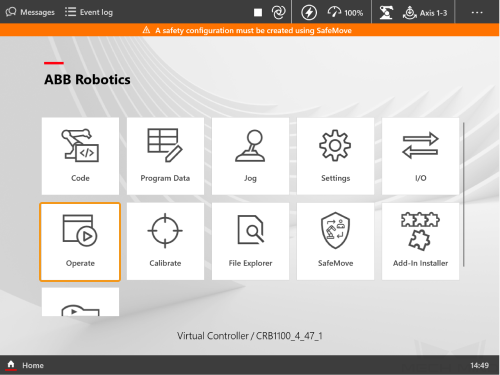

In the Home interface, tap Operate.

Tap Tasks on the left and the list of tasks will be expanded. Tap Advanced on the right and the advanced settings will appear.

In the list of tasks, select T_ROB1, and select Reset Program Pointer to Main.

Select Yes in the pop-up window.

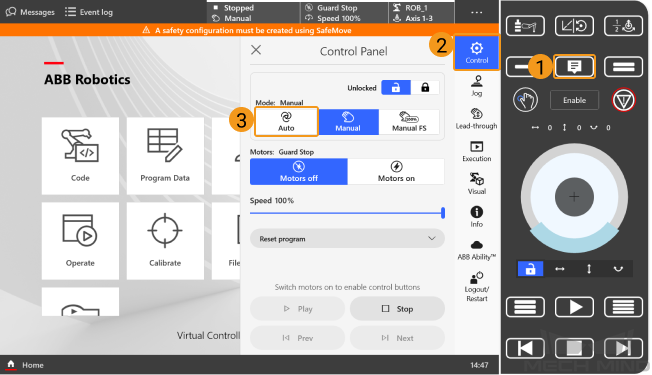

Run the Program

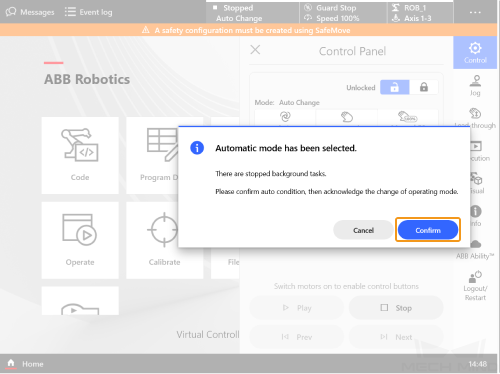

Tap

to open the Control Panel, and select .

to open the Control Panel, and select .Select Confirm in the pop-up window.

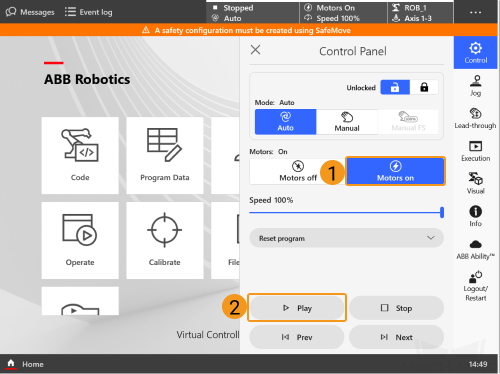

Select to run the program.

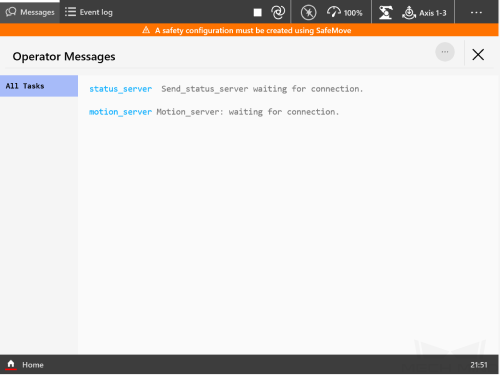

Tap Messages in the upper left corner to view the Operator Messages. If messages as shown below appear, the program has been successfully loaded on the robot end.

Test Robot Connection¶

Configure Robot in Mech-Viz¶

Open Mech-Viz, click New project to create a new project.

Select the robot model in use in the next page.

Save the project by pressing Ctrl + S.

In the toolbar, change the Vel. (velocity) and Acc. (acceleration) parameters to 5%.

Right-click the project name in Resources and select Autoload Project.

Configure Settings in Mech-Center¶

Open Mech-Center and click on Deployment Settings.

Go to Robot Server, and make sure Use robot server is checked.

Check if the robot model displayed next to Robot type in Mech-Viz project matches the one in use.

Set the Robot IP address, and click Save.

Connect to Robot in Mech-Center¶

Click Connect Robot on the toolbar.

The robot is successfully connected if:

A message saying Robot: server connected to the robot shows up in the Log panel, and

A robot icon with the robot model shows up in the Service Status panel.

Move the Robot¶

In Mech-Viz, click Sync Robot on the toolbar to synchronize the pose of the real robot to the simulated robot. Then, click Sync Robot again to disable the synchronization.

Click the Robot tab in the lower right, and change the joint position of J1 slightly (for example, from 0° to 3°). The simulated robot will move accordingly.

Click Move real robot, the real robot should move accordingly.

Attention

When moving the robot, please pay attention to safety hazards. In the case of an emergency, press the emergency stop button on the teach pendant!

Troubleshooting¶

If the program has been loaded but the robot cannot be connected successfully, please check whether the following requirements have been met.

IPC end:

The firewall is turned off.

The IPC can communicate with the robot IP address with the ping command in the command prompt.

There is no interference from any antivirus software.

Two network ports of the IPC belong to different subnets and there is no conflict.

If the IPC is connected via a router, there is no interference from other network cables.

Robot end:

The Ethernet cable is connected to the WAN port of the controller properly.

The robot IP address is set correctly. Please ensure that the set IP address is that of the WAN port instead of others.

You have run the program on the robot end.