OBJ Models Simplification¶

Basic Methods¶

The size of the end effector model file should be as samll as possible and less than 1MB.

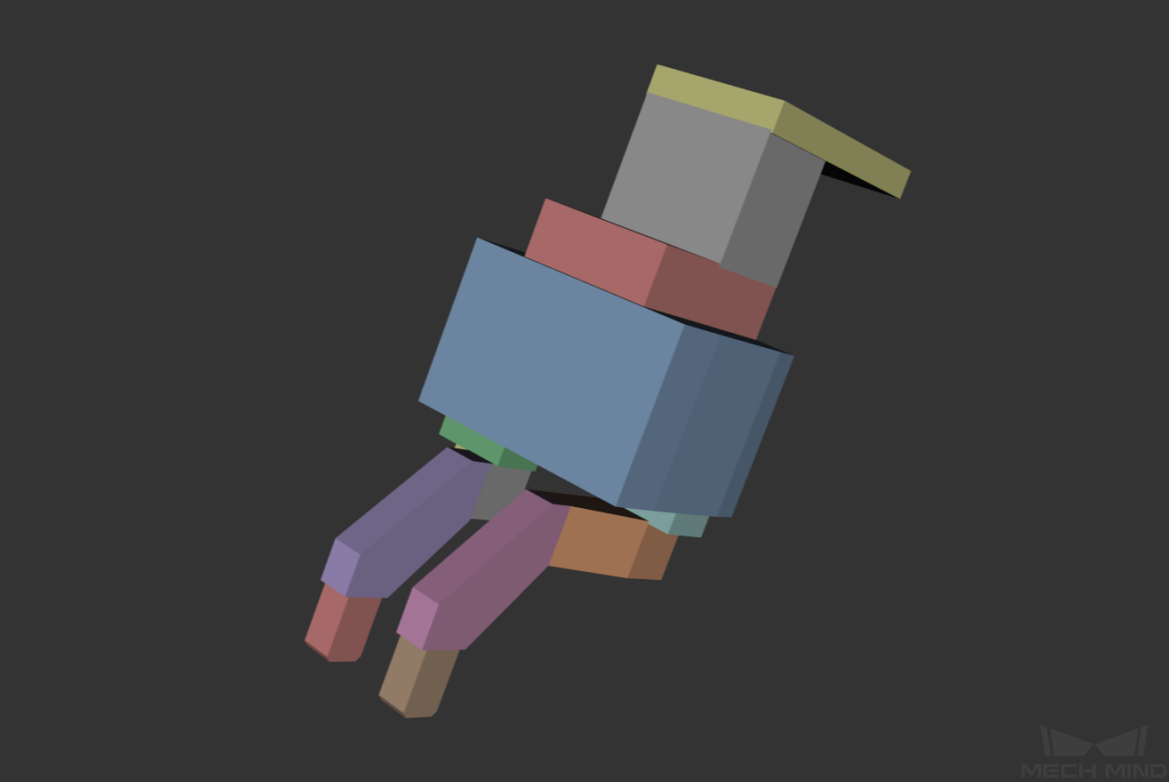

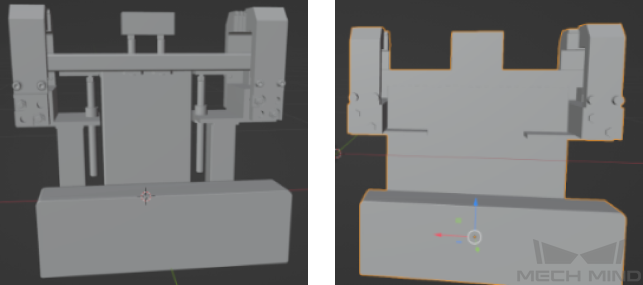

The end effector model should be processed into a combination of multiple convex polyhedra, as shown below.

The unnecessary details on the surface of the model should be removed.

Make the model into a combination of multiple convex polyhedra¶

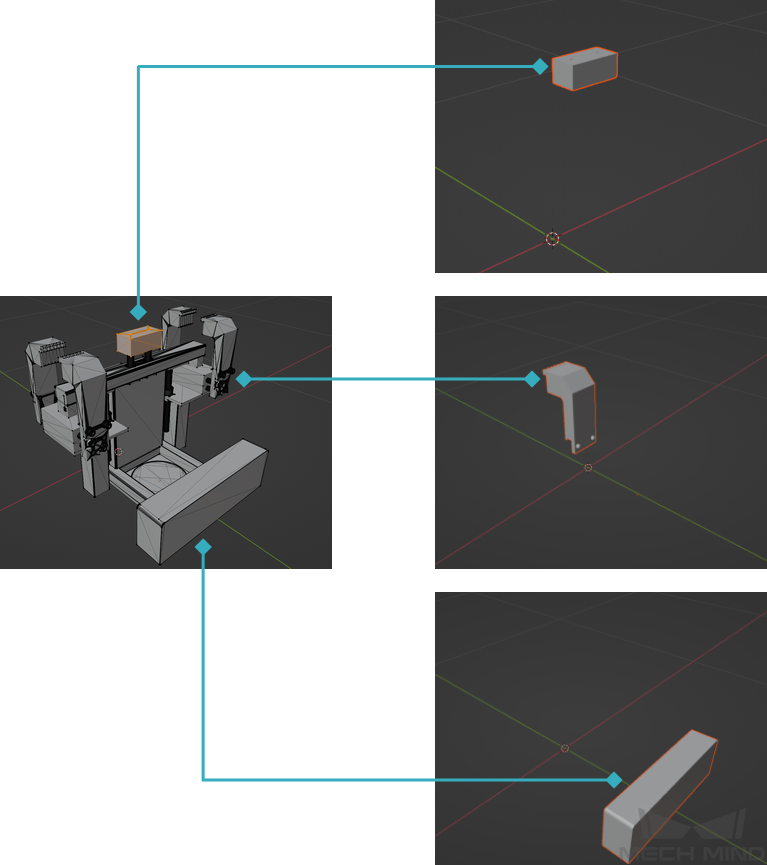

Split the object into multiple parts, as shown below. Process the parts into convex polyhedra, and then assembly the processed parts into one piece and export in OBJ format.

Remove unnecessary surface features¶

Similar as STL files, too many surface features of the model may slow down the computation speed in the project. In order to increase the processing efficiency, the unnecessary surface features of models in OBJ format should be removed as well.

The unnecessary surface features mainly includes the following:

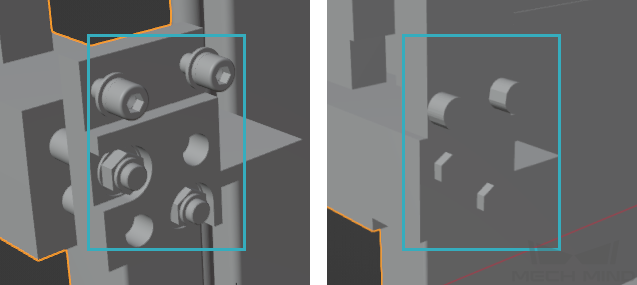

Round parts, such as screws, screw threads, through-holes, countersunk holes, gaskets, chamfers, fillets, suction cups, etc. The threaded holes, screws and other structures on the end effector should be kept and simplified as well, as shown in the following figure.

Interior structures, such as that of an end effector or camera. For example, the camera can be simplified as a cuboid, and the unnecessary interior structure can be wrapped inside the polyhedra directly, as shown below.

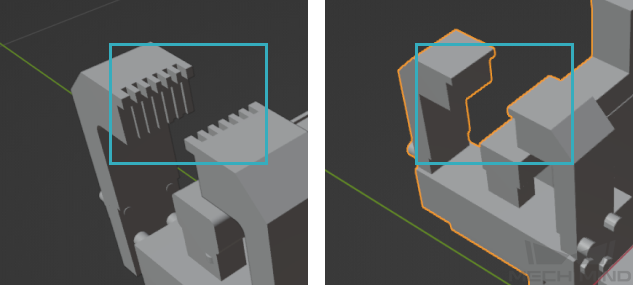

Surface features, such as serrations, screw threads, etc., as shown below.

Keep the original shape of the end effector¶

Keep the basic shape of the end effector, such as protrusions, curved parts, and the shape of the gripper, as shown below.

Adjust the shape of the end effector according to actual needs¶

For projects with high requirements on collision detection, even a slight deviation will lead to a collision or damage to the workobjects, and therefore the details of the end effector should be emphasized.

Parts of the end effector that will not collide with the point clouds of workobjects and scene objects during picking can be removed.

Adjust the lines of the end effector model according to the actual situation of the project to make it more reasonable.

Hint

Mech-Viz provides a built-in model editor to simplify models. Please refer to Model Editor for detailed instructions.