Siemens PLC Client - SIMATIC STEP 7¶

The SIMATIC STEP7 software communicates with the Mech-Mind Software Suite using the Mech-Center standard interface Siemens PLC Client.

The procedure is as follows:

Software and Hardware Prerequisites¶

Hardware¶

The following S7 series PLCs from Siemens are supported:

S7-300: Integrated PN network port or CP343-1

S7-400: Integrated PN network port or CP443-1

Power adapter of 220V AC to 24V DC

IPC or host for Mech-Mind Vision System

Network cable

Software¶

Siemens PLC programming software SIMATIC Manager Step7 V5.6.

Control center software Mech-Center 1.4.0 and above, machine vision software Mech-Vision 1.4.0 and above, robot programming software Mech-Viz 1.4.0 and above.

Communication interface file between Vision system and S7: MM_Interface_Step7.AWL.

Hint

MM_Interface_Step7.AWL file storage path: XXXX/Mech-Center-xxx/Robot_Interface/Siemens Snap7/Simatic Manager-STEP7 under the Mech-Center software installation path in the IPC of the Mech-Mind Vision System or the host.

PLC Project Building and Deployment¶

Create a PLC Project¶

Open the software SIMATIC Manager, click the button

in the upper left corner, enter the project name and storage path in the pop-up window.

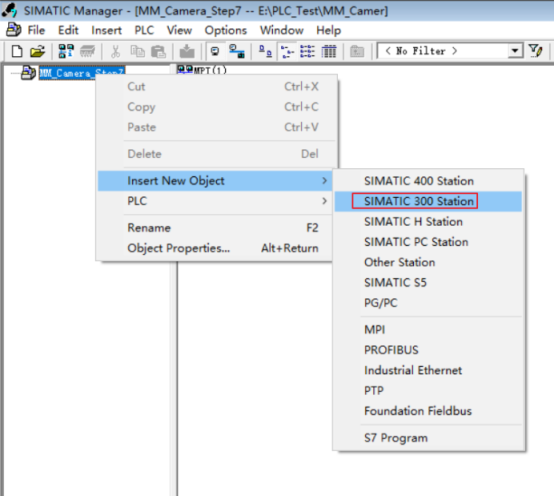

in the upper left corner, enter the project name and storage path in the pop-up window.Right-click MM_Camera_Step7 , select . After inserting, right-click and select Open Project to enter the hardware configuration interface.

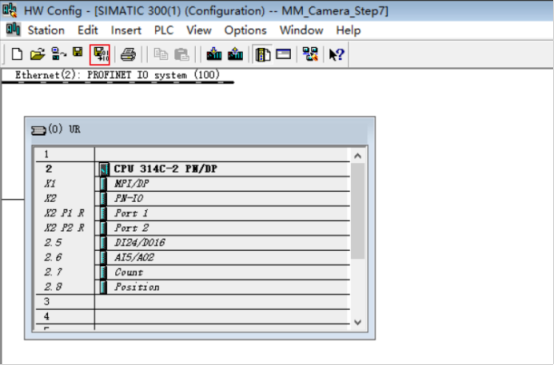

In the blank space of the hardware configuration interface, click the right mouse button and select to insert the mounting rail.

In the second row slot of the mounting rail, right-click, select Insert Object, select the module that is consistent with the PLC CPU (the module has to support the PN network port), and the Ethernet Interface Property window will pop up.

After setting the IP address, click New Subnet (the subnet name can be set as the default name), then select the newly created subnet, and click OK .

After clicking

Compile and Save on the title bar, close the Hardware Configuration window.

Compile and Save on the title bar, close the Hardware Configuration window.

Import the S7 Communication Interface¶

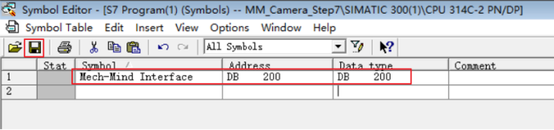

Return to the SIMATIC Manager main interface, select S7 Program, right-click, open the Symbols table, add a new symbol Mech-Mind Interface, and select an unoccupied number for the DB number in the address column.

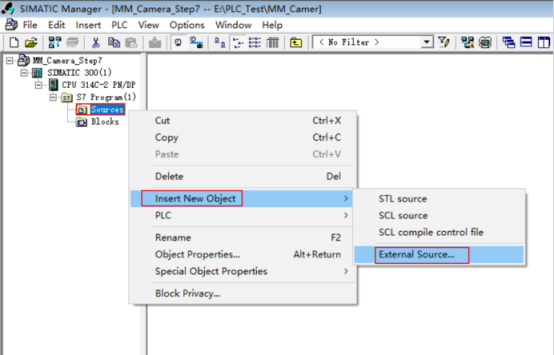

Right-click Sources in the project section on the left, select in turn, select MM_Interface_Step7.AWL in the pop-up window and open it.

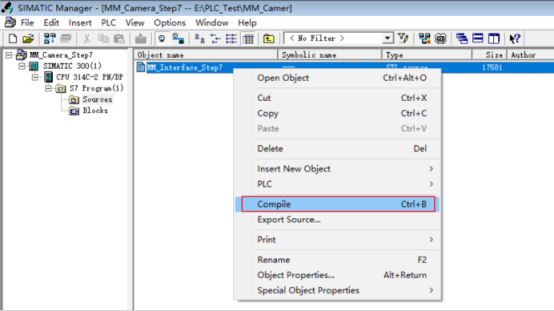

Right-click and select MM_Interface_Step7 , select Compile , and close the window after the compilation is successful.

Select Blocks , right-click and select Details , and you can find that Mech-Mind Interface has been imported successfully.

Right-click SIMATIC 300 in the project section on the left. Click the button

Download on the tool bar to download the project to the CPU.

Download on the tool bar to download the project to the CPU.

Configure Mech-Center and Start Communication¶

Mech-Center Communication Configuration¶

Make the IP address of the IPC and the IP of the PLC in the same network segment, such as 192.168.1.10, open the cmd command prompt of the industrial computer (you can enter by searching for cmd), and enter ping xxx.xxx.xxx.xxx (IP address of the PLC) to see whether the connection between the industrial computer and the PLC is normal.

Run Mech-Center and open Deployment Settings .

Do the following in Deployment Settings:

Under Mech-Interface, check Use Mech-Interface.

Select Standard Interface for Interface Service Type.

Select Siemens PLC Client under Interface Options;

Please select the robot model according to the actual usage.

Set the slot number to 2, set the DB number to 200, i.e., the number of Mech-Mind Interface in the PLC project. Click Save to exit Deployment Settings.

Start Mech-Center Communication¶

On the main interface of Mech-Center, click

Start Interface. If the connection is successfully established, Connect to PLC server successfully will be displayed in the log column on the right side of the interface; if not, please check the configuration and check whether the physical connection is normal.

Start Interface. If the connection is successfully established, Connect to PLC server successfully will be displayed in the log column on the right side of the interface; if not, please check the configuration and check whether the physical connection is normal.Start the deployed Mech-Vision and Mech-Viz projects.

Hint

For the specific usage of DB and interface communication instructions, please refer to Siemens PLC and PROFINET - Siemens SIMATIC S7 PLC 。